LMF Metal Cap Flashing (Parapet-to-Wall Transition - Site Formed)

LMF Metal Cap Flashing (Parapet-to-Wall Transition - Site Formed)

Division D - Construction Details

LMF | Metal Cap Flashing (Parapet-to-Wall Transition - Site Formed)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the requirements of the Standard they represent. Unless otherwise required by the Standard, dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of the referenced requirements can be read in any Standard and may be read by using the blue hyperlinks | |

Metal Flashing Details

1 FABRICATION PROCEDURE

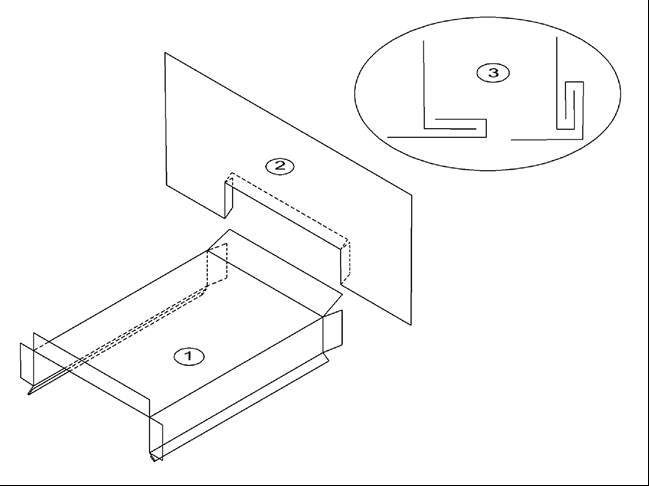

- (1) Metal Cap Flashing

- Cut to form a 25mm (1") wide flange for seam fabrication at cap flashing /wall transitions. Fasten outside face with continuous concealed clip-type fasteners or with two concealed discontinuous clips or cladding screws evenly spaced between seams. Cap flashing over 100 mm (4") in width must provide positive slope to roof area.

- (2) Gusset Flange

- Site fabricated a minimum of 100mm (4") wider than the top, inside and outside face of metal cap flashing. Metal gusset flange to match profile of cap flashing with an additional allowance of 12.7 mm (1/2") of material for seaming. Gusset Flange must lap under sheathing membrane and wall cladding or finish by a minimum of 75mm (3").

- (3) Double Fold Seam

- Site formed standing seam folded flat on back surface of wall transition gusset to form double fold seam. Optional: Install polyurethane caulking seam tape prior to forming double folded seam.

NOTE: See the related Standard for additional requirements.

© RCABC 2025

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.