Difference between revisions of "SBS Expansion Joint (Field)"

Difference between revisions of "SBS Expansion Joint (Field)"

(→RELATED WORK BY OTHERS) |

(→WORK INCLUDED) |

||

| (36 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | {{Template:RPM Info}} | |

| − | = | + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} |

| − | ( | + | __NOTOC__ |

| − | ( | + | <big><big>Division D - Construction Details</big></big> |

| + | <hr> | ||

| + | <big><big><big><big><big>SBS | Expansion Joint (Field) ([[SBS_Roof_Systems_Standard#10.3.6.1._Expansion_Joints | Article 10.3.6.1.]])</big></big></big></big></big> | ||

| + | {{Template:Construction Details Header}} | ||

| + | <div class="panel panel-success"> | ||

| + | <div class="panel-heading"><big>'''SBS Details'''</big></div> | ||

| + | <div class="panel-body"> | ||

| + | <div class="col-md-6"> | ||

| + | <div style="text-align:center; vertical-align:center"> | ||

| + | [[File:Part 10 - SBS Expansion Joint (field).png|link=https://rpm.rcabc.org/images/3/3a/Part_10_-_SBS_Expansion_Joint_%28field%29.png | class=img-responsive]] | ||

| + | </div> | ||

| + | </div><!-- COL-MD-6 --> | ||

| − | (3) | + | <div class="col-md-6"> |

| + | === WORK INCLUDED === | ||

| + | ;(1) [[SBS Roof Systems Standard#PART_10|'''Base sheet membrane flashing''']]: Waterproofs the expansion joint structure and provides a base layer for the control joint material to bond with. | ||

| + | ;(2) [[SBS Roof Systems Standard#PART_10|'''Expansion joint (elastomeric product illustrated)''']]: This joint is proprietary to its manufacturer and will be fitted, manufactured, and installed (or its installation supervised) by others. Secured to substrate as required by manufacturer. | ||

| + | ;(3) '''Reinforced membrane strip''': Applied to cover the control joint and seal it to the base membrane system. | ||

| + | ;(4) [[SBS Roof Systems Standard#PART_10|'''Cap sheet membrane flashing''']]: Installed as required in Part 10 and applied as the second or third of a two or three-ply membrane system, providing required coverage above the finished roof system surface. Smooth membrane is shown on parapet coping (may be granule-surfaced, depending on material specified). | ||

| + | ;(5) [[SBS Roof Systems Standard#PART_13|'''Metal cap (coping) flashing''']]: Fabricated and installed as required in Part 13. | ||

| + | ;(6) [[SBS Roof Systems Standard#PART_13|'''Metal counter-flashing''']]: The counter-flashing below the cap flashing is secured independently of the metal cap flashing to permit movement of the expansion joint assembly across the planes of anticipated structural movement. Dimensions are project-specific. | ||

| − | |||

| − | + | <hr> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | (A) | + | ;(A) [[SBS Roof Systems Standard#PART_2|'''Acceptable deck''']] |

| − | + | ;(B) '''Expansion joint structure''' | |

| − | (B) < | + | </div><!-- COL-6-MD --> |

| − | + | </div><!-- PANEL BODY --> | |

| − | + | </div><!-- PANEL --> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | '''NOTE''': See the [[SBS Roof Systems Standard | '''Standard''']] for additional requirements. | ||

<hr> | <hr> | ||

| + | [[SBS Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''"SBS" Roof System Details'']] | ||

| + | [[Main Page | <i class="fa fa-home fa"></i> Home]] | ||

| − | + | {{Tempate:RPM Page Footer with Copyright and Current Date}} | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 16:29, 12 December 2022

Division D - Construction Details

SBS | Expansion Joint (Field) ( Article 10.3.6.1.)

| Notice to Reader | |

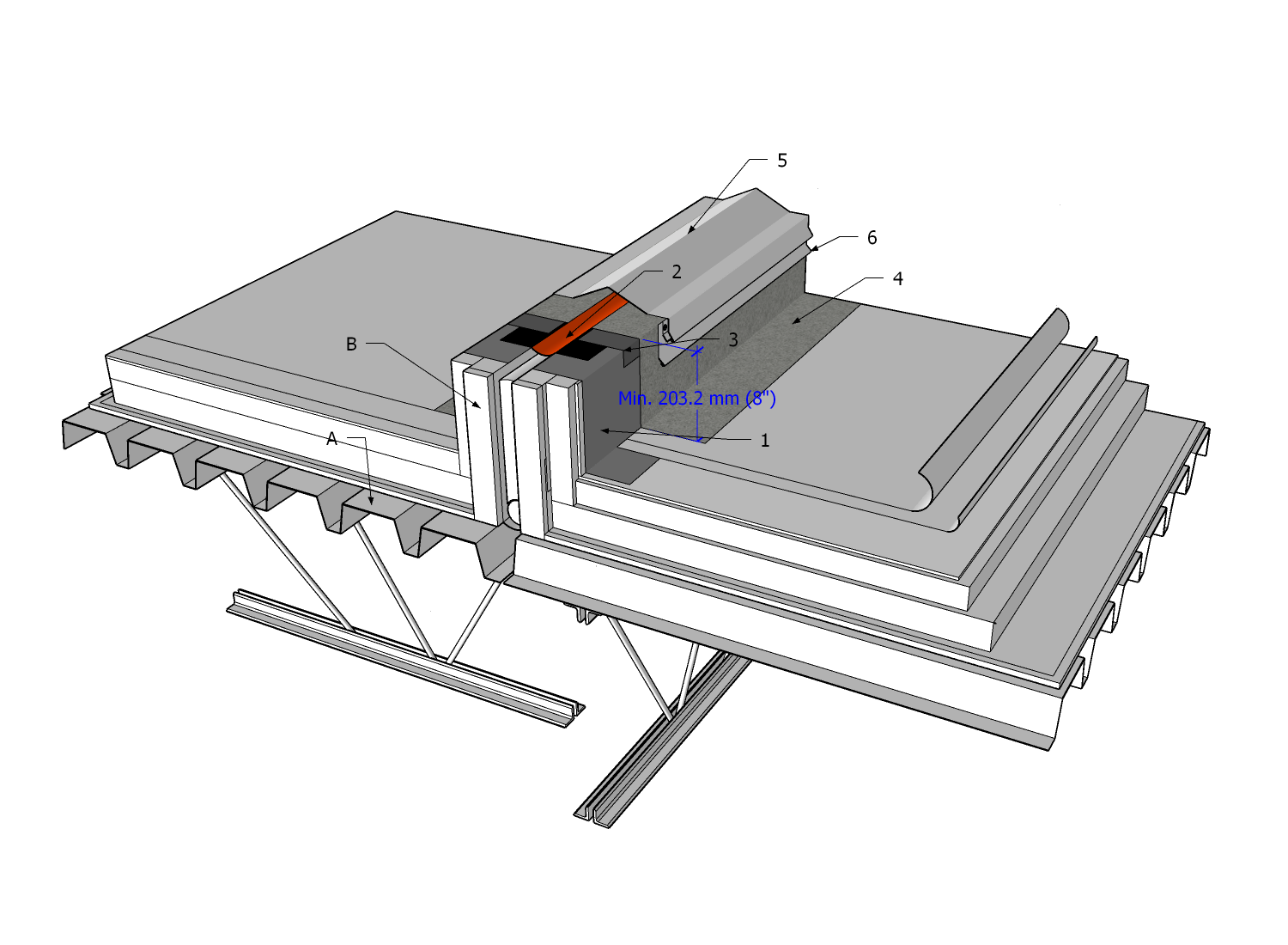

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

SBS Details

1 WORK INCLUDED

- (1) Base sheet membrane flashing

- Waterproofs the expansion joint structure and provides a base layer for the control joint material to bond with.

- (2) Expansion joint (elastomeric product illustrated)

- This joint is proprietary to its manufacturer and will be fitted, manufactured, and installed (or its installation supervised) by others. Secured to substrate as required by manufacturer.

- (3) Reinforced membrane strip

- Applied to cover the control joint and seal it to the base membrane system.

- (4) Cap sheet membrane flashing

- Installed as required in Part 10 and applied as the second or third of a two or three-ply membrane system, providing required coverage above the finished roof system surface. Smooth membrane is shown on parapet coping (may be granule-surfaced, depending on material specified).

- (5) Metal cap (coping) flashing

- Fabricated and installed as required in Part 13.

- (6) Metal counter-flashing

- The counter-flashing below the cap flashing is secured independently of the metal cap flashing to permit movement of the expansion joint assembly across the planes of anticipated structural movement. Dimensions are project-specific.

2 RELATED WORK BY OTHERS

- (A) Acceptable deck

- (B) Expansion joint structure

NOTE: See the Standard for additional requirements.

Back to "SBS" Roof System Details

© RCABC 2024

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.