Difference between revisions of "SBS Protected Roof Assembly (typical)"

Difference between revisions of "SBS Protected Roof Assembly (typical)"

| (28 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | { | + | {{Template:RPM Info}} |

| − | | | + | |

| − | + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | |

| + | __NOTOC__ | ||

| + | |||

| + | <big><big>Division D - Construction Details</big></big> | ||

| + | <hr> | ||

| + | <big><big><big><big><big>SBS | Protected Membrane Roof Assembly (Typical) ([[SBS_Roof_Systems_Standard#1.1.3.1._Permitted_Roof_Systems | Article 1.1.3.1.]])</big></big></big></big></big> | ||

| + | {{Template:Construction Details Header}} | ||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

| − | <div class="panel-heading"><big>''' | + | <div class="panel-heading"><big>'''Metal Flashing Details'''</big></div> |

<div class="panel-body"> | <div class="panel-body"> | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | [[File: | + | [[File:SBS 1.3.1-3 PMRA.jpg|class=img-responsive]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</div> | </div> | ||

| Line 20: | Line 19: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[ | + | ;(1) [[SBS Roof Systems Standard#PART_9|'''Base Membrane (field)''']]: See Tables '''9.1''' and '''9.2''' for acceptable membrane types and application methods. |

| − | + | ;(2) [[SBS Roof Systems Standard#PART_10|'''Base Membrane (flashing)''']]: Carried vertically up a wall or parapet (membrane flashing must extend up the vertical plane, and above the ''Finished Roof/Waterproofing Surface'', at least 200 mm (8”), and must extend onto the roof field at least 100 mm (4”) (greater if required by the membrane manufacturer). | |

| − | ;(2) [[ | + | ;(3) [[SBS Roof Systems Standard#PART_9|'''Cap Membrane (field)''']]: May be an ungranulated base membrane when protected from UV light. See Tables '''9.1''' and '''9.2''' for acceptable ‘film’ cap membrane types. |

| − | ;(3) [[ | + | ;(4) [[SBS Roof Systems Standard#PART_10|'''Cap Membrane (flashing)''']]: Extended vertically past the termination of the base membrane flashing, to provide a positive seal at the top edge. Membrane flashing must be protected from UV light exposure; use a granulated surface membrane (as illustrated) or cover with metal flashing. Terminate membrane following the requirements in '''10.1.2.2''' ('''16'''). For perimeters that require hot works-specific applications, see '''10.3.3 Alternate Membrane Flashing Approaches'''. |

| − | ;(4) [[ | + | ;(5) [[SBS Roof Systems Standard#PART_12|'''Drainage Layer''']]: Required below XPS insulation in a PMRA (an additional drainage layer is sometimes required above the insulation. See '''14.1.2.1''' ('''5''')('''4'''). In all other cases, a second drainage layer above the insulation is discretionary). Turn the drainage layer up at the perimeter to convey water to the drains. |

| − | ;(5) [[ | + | ;(6) [[SBS Roof Systems Standard#PART_7|'''Insulation''']]: XPS insulation, ideally installed in multiple layers that are offset and staggered as illustrated (for both system stability and thermal effectiveness). |

| − | ;( | + | ;(7) [[SBS Roof Systems Standard#PART_12|'''Filter Fabric''']]: Installed above XPS insulation, and tucked behind the base metal flashing, to contain insulation and prevent ‘stacking’ (see '''12.1.1''' ('''1''')('''3''')('''1''')), and to prevent fine material from settling down to the membrane ('''12.1.1''' ('''1''')('''3''')('''2''')). |

| − | ;( | + | ;(8) [[SBS Roof Systems Standard#PART_12|'''Ballast''']]: Considered part of the roof system (ballast functions as securement against both flotation and wind uplift), ballast must be installed by the Contractor (see '''Section 12.1'''). This requirement is waived when a ''Vegetated Roof System'' (VRS) that is installed by others serves as ballast (see '''12.1.3.1''' ('''1''')); in such situations, the VRS must be installed immediately after the Contractor’s work and coordinated with the Contractor to ensure the roof system remains unaffected by wind or flotation and is not damaged by others. See also '''1.6 RoofStar Guarantee: Coverage and Limitations''' concerning integrity scans when overburden is installed by someone other than the Contractor ('''1.6''' ('''6''')). |

| − | ;( | + | ;(9) [[SBS Roof Systems Standard#PART_13|'''Metal Base Flashing''']]: Fabricated and secured according to the requirements in Part '''13 METAL FLASHINGS'''. |

| − | |||

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[ | + | ;(A) [[SBS Roof Systems Standard#PART_2|'''Acceptable Deck''']]: |

| − | + | ;(B) Suitable Wall Sheathing: If and as required. | |

| − | ;(B) | + | ;(C) [[SBS Roof Systems Standard#PART_10|'''Sloped Parapet Top''']]:Sloped to roof where parapet is over 100 mm (4") in width. |

| − | + | ;(D) Wall or Parapet Structure | |

| − | ;(C) [[ | ||

| − | :Sloped to roof where parapet is over 100 mm (4") in width. | ||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

</div><!-- PANEL BODY --> | </div><!-- PANEL BODY --> | ||

</div><!-- PANEL --> | </div><!-- PANEL --> | ||

| − | '''NOTE''': | + | '''NOTE''': See the [[SBS Roof Systems Standard | '''Standard''']] for additional requirements. |

| − | |||

<hr> | <hr> | ||

| + | [[SBS Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''"SBS" Roof System Details'']] | ||

| − | [[ | + | [[Main Page | <i class="fa fa-home fa"></i> Home]] |

| − | |||

| − | |||

| − | + | {{Tempate:RPM Page Footer with Copyright and Current Date}} | |

Latest revision as of 17:37, 27 October 2023

Division D - Construction Details

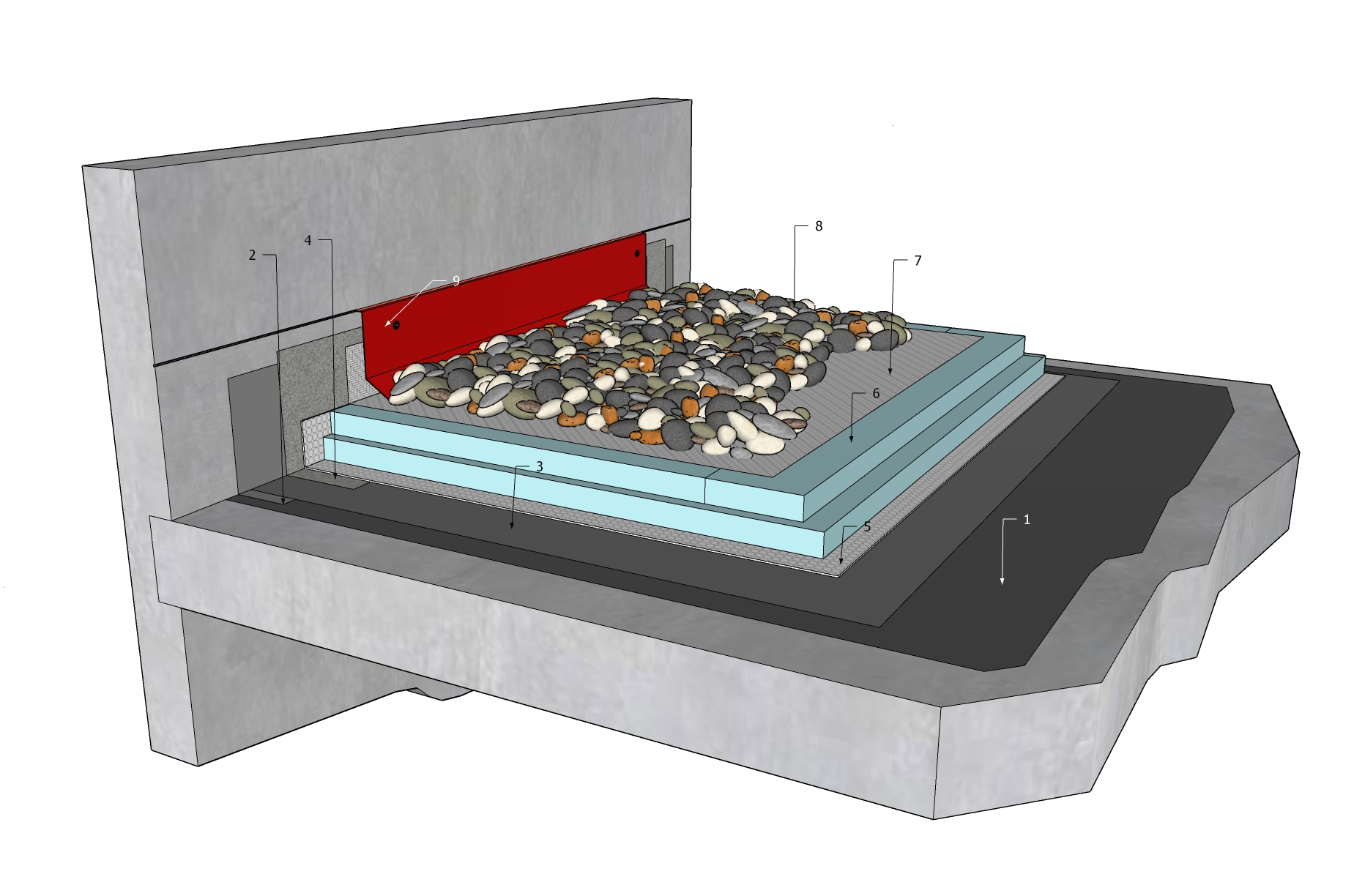

SBS | Protected Membrane Roof Assembly (Typical) ( Article 1.1.3.1.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

Metal Flashing Details

1 WORK INCLUDED

- (1) Base Membrane (field)

- See Tables 9.1 and 9.2 for acceptable membrane types and application methods.

- (2) Base Membrane (flashing)

- Carried vertically up a wall or parapet (membrane flashing must extend up the vertical plane, and above the Finished Roof/Waterproofing Surface, at least 200 mm (8”), and must extend onto the roof field at least 100 mm (4”) (greater if required by the membrane manufacturer).

- (3) Cap Membrane (field)

- May be an ungranulated base membrane when protected from UV light. See Tables 9.1 and 9.2 for acceptable ‘film’ cap membrane types.

- (4) Cap Membrane (flashing)

- Extended vertically past the termination of the base membrane flashing, to provide a positive seal at the top edge. Membrane flashing must be protected from UV light exposure; use a granulated surface membrane (as illustrated) or cover with metal flashing. Terminate membrane following the requirements in 10.1.2.2 (16). For perimeters that require hot works-specific applications, see 10.3.3 Alternate Membrane Flashing Approaches.

- (5) Drainage Layer

- Required below XPS insulation in a PMRA (an additional drainage layer is sometimes required above the insulation. See 14.1.2.1 (5)(4). In all other cases, a second drainage layer above the insulation is discretionary). Turn the drainage layer up at the perimeter to convey water to the drains.

- (6) Insulation

- XPS insulation, ideally installed in multiple layers that are offset and staggered as illustrated (for both system stability and thermal effectiveness).

- (7) Filter Fabric

- Installed above XPS insulation, and tucked behind the base metal flashing, to contain insulation and prevent ‘stacking’ (see 12.1.1 (1)(3)(1)), and to prevent fine material from settling down to the membrane (12.1.1 (1)(3)(2)).

- (8) Ballast

- Considered part of the roof system (ballast functions as securement against both flotation and wind uplift), ballast must be installed by the Contractor (see Section 12.1). This requirement is waived when a Vegetated Roof System (VRS) that is installed by others serves as ballast (see 12.1.3.1 (1)); in such situations, the VRS must be installed immediately after the Contractor’s work and coordinated with the Contractor to ensure the roof system remains unaffected by wind or flotation and is not damaged by others. See also 1.6 RoofStar Guarantee: Coverage and Limitations concerning integrity scans when overburden is installed by someone other than the Contractor (1.6 (6)).

- (9) Metal Base Flashing

- Fabricated and secured according to the requirements in Part 13 METAL FLASHINGS.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Suitable Wall Sheathing

- If and as required.

- (C) Sloped Parapet Top

- Sloped to roof where parapet is over 100 mm (4") in width.

- (D) Wall or Parapet Structure

NOTE: See the Standard for additional requirements.

Back to "SBS" Roof System Details

© RCABC 2024

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.