Difference between revisions of "SBS Structural Planter"

Difference between revisions of "SBS Structural Planter"

| Line 1: | Line 1: | ||

{{Template:RPM Info}} | {{Template:RPM Info}} | ||

| + | |||

| + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | ||

| + | __NOTOC__ | ||

| + | |||

| + | <big><big>Division D - Construction Details</big></big> | ||

<hr> | <hr> | ||

| + | <big><big><big><big><big>SBS 14.3.3 Structures and Equipment (planter pre-curb)</big></big></big></big></big> | ||

{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | {| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | ||

| colspan="2" | <big>'''''Notice to Reader'''''</big> | | colspan="2" | <big>'''''Notice to Reader'''''</big> | ||

Revision as of 18:16, 7 September 2021

Division D - Construction Details

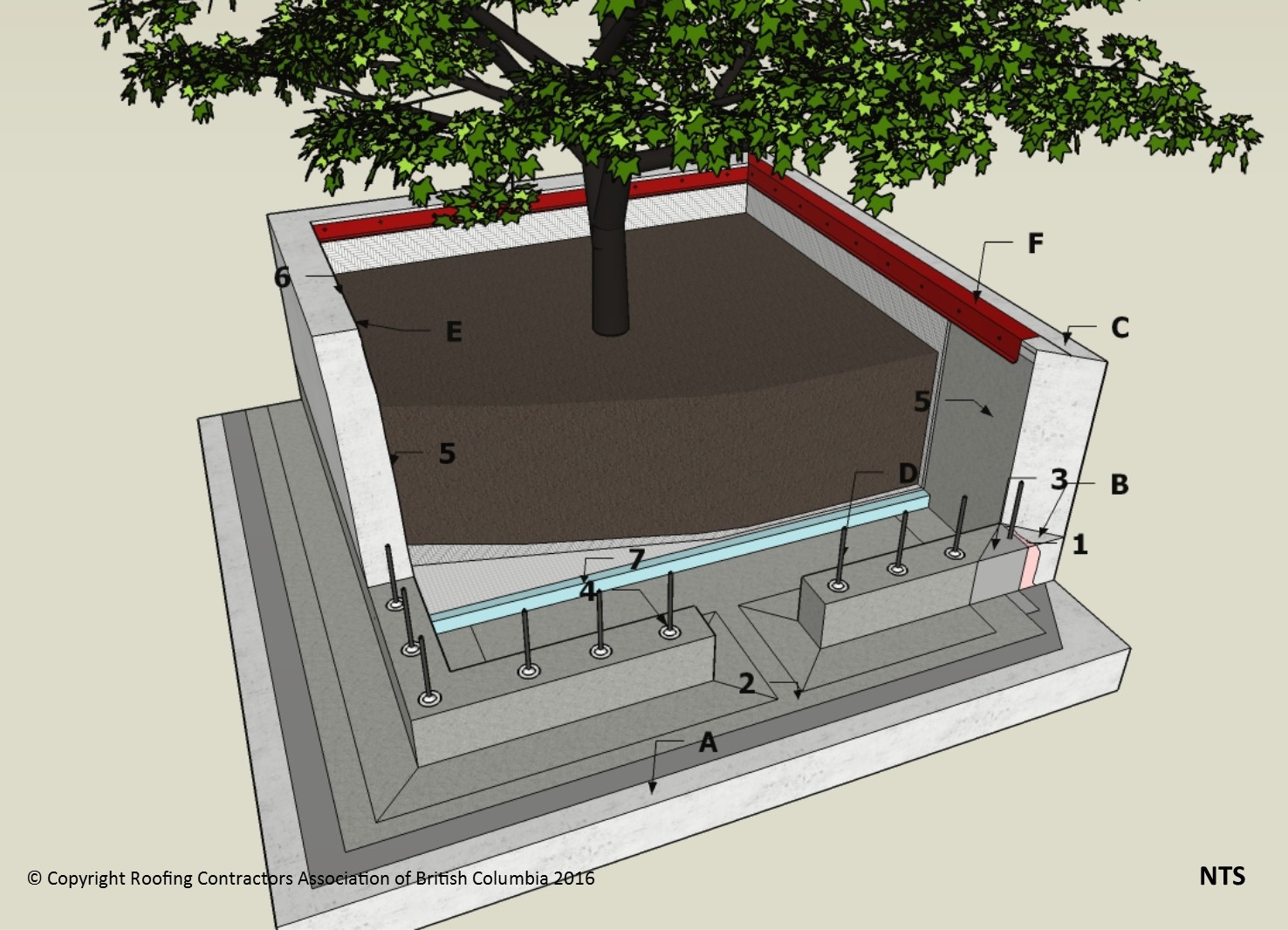

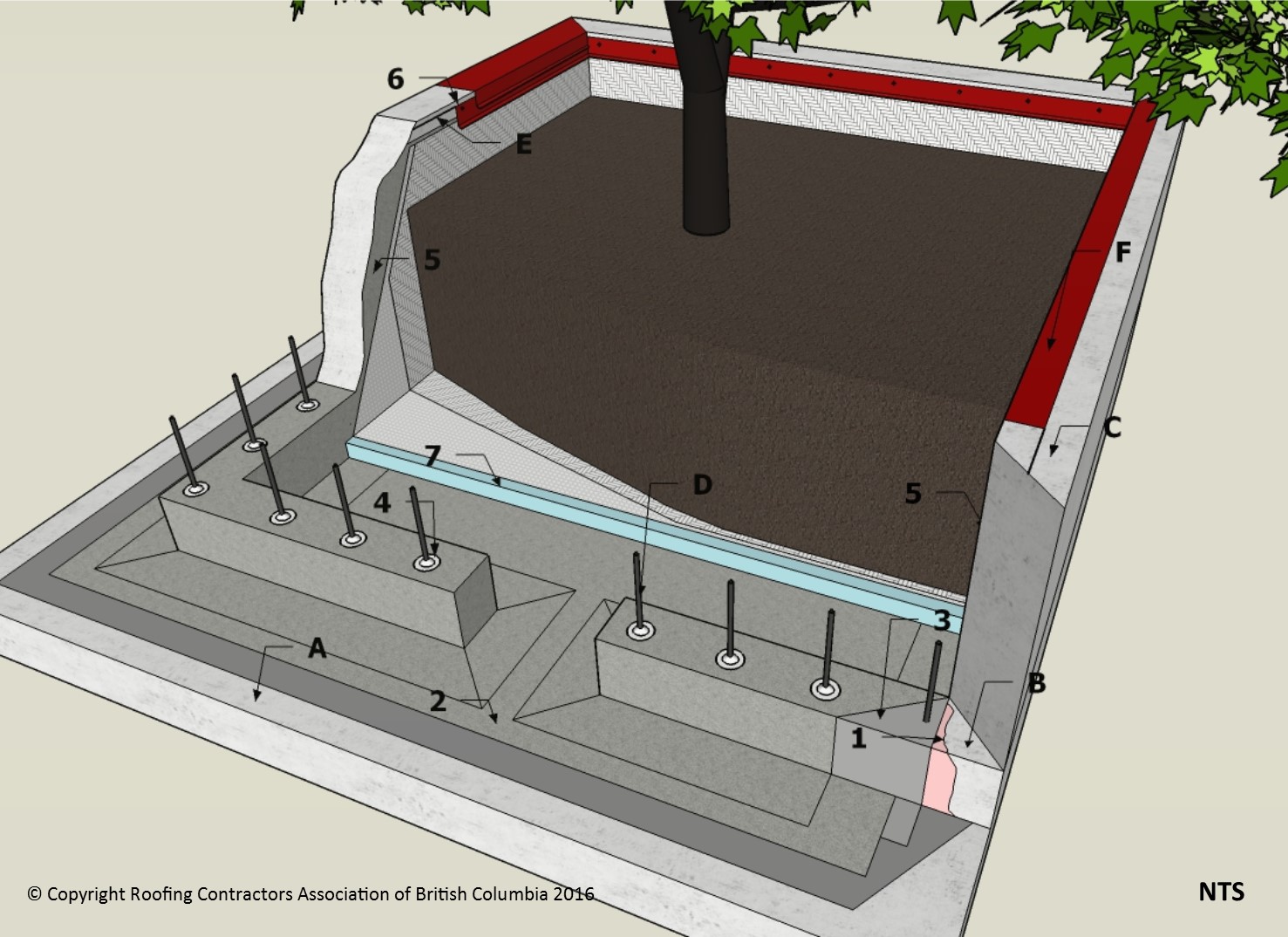

SBS 14.3.3 Structures and Equipment (planter pre-curb)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the requirements of the Standard they represent. Unless otherwise required by the Standard, dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of the referenced requirements in the Standard may be read by using the blue hyperlinks | |

SBS Details

1 WORK INCLUDED

- (1) Primer

- Application method and coverage rate as approved by Primary Membrane Manufacturer.

- (2) Primary Roof Membrane

- Modified Bituminous base and cap sheet membranes installed as per manufacturer's published application specifications.

- (3) Pre-Curb (Start-Up Curb) Membrane Flashing

- Modified Bituminous base and cap sheet membrane flashing installed as per manufacturer's published application specifications.

- (4) Proprietary Liquid Membrane Flashing

- RoofStar Guarantee Program accepted Liquid Membrane Flashing System(s) or hot melt SBS modified bitumen. (NOTE: Refer to Liquid Membrane Flashing Systems in Division C of this Manual). Install as per Manufacturer's published instructions.

- (5) Inside Planter Wall Membrane Flashing

- Adhered according to manufacturer's specifications using cold adhesive, self-adhered or torch-applied membrane. Torching directly to wood surfaces is not permitted. Carry membrane flashing plies to reglet termination near top of planter wall (stagger membrane seal minimum 300mm (6").

- (6) Reglet - Metal Counter Flashing

- As required by the RoofStar Guarantee Standards. Note that a coping flashing may be paired with the reglet flashing, as illustrated.

- (7) Plaza Deck / Planter Interior Assembly

- Extruded polystyrene insulation and filter mat over primary roof membranes. Concrete pavers placed above pre-curb membrane flashing height, on proprietary pedestals. Note: membrane flashing is not permitted above pre-curb membrane flashing on plaza deck side of planter walls.

2 RELATED WORK BY OTHERS

- (A) Acceptable Supporting Deck Structure

- Concrete slab shown. Each planter area must have a drain through the roof deck.

- (B) Pre-Curb

- Minimum of 100mm (4") in height above concrete deck, smooth dry and clean.

- (C) Cast over Concrete Planter Wall

- Form on top of membrane sealed Pre-curbs or Start-up curbs.

- (D) Re-Bar

- Placed at centre of Pre-curb.

- (E) Reglet

- Premanufactured purpose-made reglet cast in concrete wall or saw-cut.

- (F) Alternate Termination

- Horizontal Reglet alternative to pre-manufactured purpose-made reglet, cast in concrete wall or saw-cut on vertical surface of inside planter walls.

NOTE: See the Standard for additional requirements.

Back to "SBS" Roof System Details

© RCABC 2024

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.