Difference between revisions of "SBS Plumbing Vent (Conventional Roof System)"

Difference between revisions of "SBS Plumbing Vent (Conventional Roof System)"

(→WORK INCLUDED) |

|||

| (8 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{Template:RPM Info}} | {{Template:RPM Info}} | ||

| + | |||

| + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | ||

| + | __NOTOC__ | ||

| + | |||

| + | <big><big>Division D - Construction Details</big></big> | ||

<hr> | <hr> | ||

| − | + | <big><big><big><big><big>SBS | Plumbing Vent (Conventional Roof System) ([[SBS_Roof_Systems_Standard#12.3.2.1._General_Requirements_for_Flashing_Penetrations | Article 12.3.2.1.]])</big></big></big></big></big> | |

| − | + | {{Template:Construction Details Header}} | |

| − | | | ||

| − | |||

| − | |||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

<div class="panel-heading"><big>'''SBS Details'''</big></div> | <div class="panel-heading"><big>'''SBS Details'''</big></div> | ||

| Line 11: | Line 13: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | [[File: | + | <br> |

| + | [[File:Part 12 - CD - Plumbing Vent - SBS.png| link=https://rpm.rcabc.org/images/7/78/Part_12_-_CD_-_Plumbing_Vent_-_SBS.png | class=img-responsive]] | ||

</div> | </div> | ||

</div><!-- COL-MD-6 --> | </div><!-- COL-MD-6 --> | ||

| Line 17: | Line 20: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

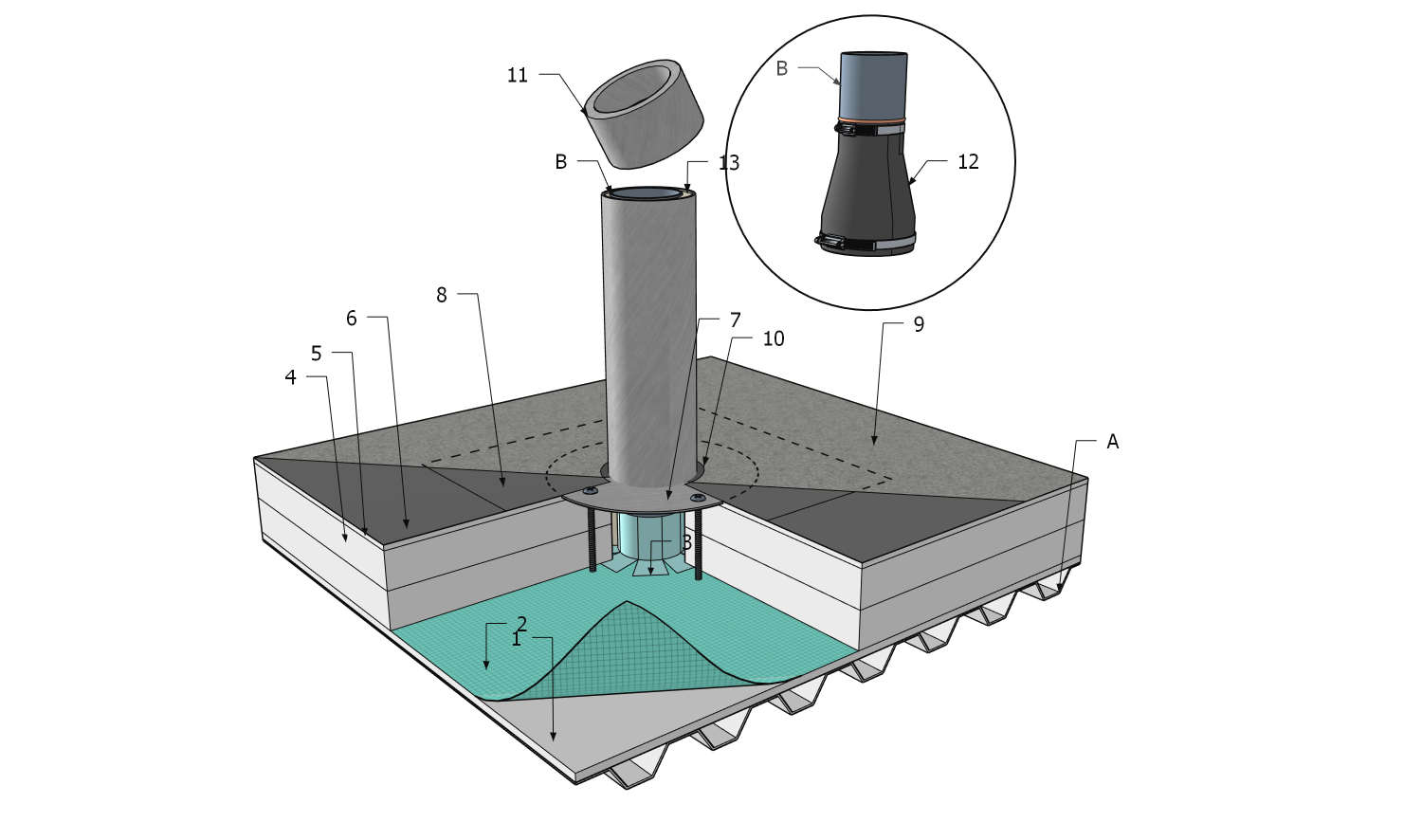

| − | ;(1) [[SBS Roof Systems Standard#PART_5|'''Supporting Deck Overlay''']]: If | + | ;(1) [[SBS Roof Systems Standard#PART_5|'''Supporting Deck Overlay''']]: If specified and included in a ''Tested Assembly'', an ''Assembly with Proven Past Performance'', or a custom-engineered assembly. |

| − | ;(2) [[SBS Roof Systems Standard#PART_6|'''Air or Vapour Control Layers''']]: | + | ;(2) [[SBS Roof Systems Standard#PART_6|'''Air or Vapour Control Layers''']]: As required by ''Design Authority''. |

| − | ;(3) [[SBS Roof Systems Standard# | + | ;(3) [[SBS Roof Systems Standard#PART_6|'''Air or Vapour Control Layer Tie-in''']]: Illustrated to show AVB continuity with penetration. |

| − | ;( | + | ;(4) [[SBS Roof Systems Standard#PART_7|'''Insulation''']]: Multiple layering shown (Refer to '''Part 7''' for design, material, and installation requirements). |

| − | ;( | + | ;(5) [[SBS Roof Systems Standard#PART_8|'''Insulation Overlay''']]: As required by the RGC Standard; see '''Part 8''' for design, material, and installation requirements. Additionally, an overlay is required is included in a ''Tested Assembly'', an ''Assembly with Proven Past Performance'', or a custom-engineered assembly. |

| − | ;( | + | ;(6) [[SBS Roof Systems Standard#PART_9|'''Field Base Sheet Membrane''']]: Selected to conform to the requirements in [https://rpm.rcabc.org/index.php?title=SBS_Roof_Systems_Standard#9.2.1.1._Membrane_Composition,_Thickness,_and_Selection '''Table 9.2.1.1.'''] and conforming to the options or requirements in a ''Tested Assembly'', an ''Assembly with Proven Past Performance'', or a custom-engineered assembly. |

| − | ;( | + | ;(7) [[SBS Roof Systems Standard#PART_12 | '''Penetration Flashing''']]: Purpose-made non-ferrous plumbing vent flashing with separate settlement cap (Item 11), sized to fit the penetration, bedded in a membrane-compatible mastic, and installed with screw fasteners. Aluminum flashings are required for torch-applied ''roof systems''. |

| − | ;( | + | ;(8) [[SBS Roof Systems Standard#PART_12 | '''Membrane Target Patch''']]: Sized to extend at least 101.6 mm (4”) past the edge of the penetration flashing flange and sealed to the field membrane and primed flange. |

| + | ;(9) [[SBS Roof Systems Standard#PART_9|'''Field Cap Sheet Membrane''']]: Selected to conform to the requirements in [https://rpm.rcabc.org/index.php?title=SBS_Roof_Systems_Standard#9.2.1.1. Membrane Composition, Thickness, and Selection '''Table 9.2.1.1.'''] and conforming to the options or requirements in a ''Tested Assembly'', an ''Assembly with Proven Past Performance'', or a custom-engineered assembly. | ||

| + | ;(10) '''Mastic''': Applied to edge of membrane and immediately covered with granules (not shown). | ||

| + | ;(11) [[SBS Roof Systems Standard#PART_12 | '''Settlement Cap''']]: Sized to fit both inside the penetration pipe (to direct rainwater into the penetration) and outside the flashing (a snug fit, secured with a screw, is required to keep the cap in place). | ||

| + | Optional: Vandal-proof cap (not shown). | ||

| + | ;(12) [[SBS Roof Systems Standard#PART_12 | '''EPDM Membrane Wrap (Optional)''']]: Used when the plumbing pipe cannot be cut down to fit inside the flashing (Refer to Article 12.3.2.1., Sentence (16)). | ||

| + | ;(13) [[SBS Roof Systems Standard#PART_12 | '''Flashing Insulation''']]: Factory-applied for insulated flashings, used where condensation between the pipe and the flashing is possible. | ||

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[SBS Roof Systems Standard#PART_2|''' | + | ;(A) [[SBS Roof Systems Standard#PART_2|'''Supporting (Structural) Roof Deck''']]: Steel deck illustrated. |

| − | ;(B) '''Plumbing | + | ;(B) '''Plumbing Penetration''': Extend to match top of metal flashing. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

</div><!-- PANEL BODY --> | </div><!-- PANEL BODY --> | ||

| Line 46: | Line 50: | ||

[[SBS Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''"SBS" Roof System Details'']] | [[SBS Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''"SBS" Roof System Details'']] | ||

| − | [[ | + | [[RCABC Roofing Practices Manual | <i class="fa fa-home fa"></i> Home]] |

{{Tempate:RPM Page Footer with Copyright and Current Date}} | {{Tempate:RPM Page Footer with Copyright and Current Date}} | ||

Latest revision as of 23:27, 6 November 2025

Division D - Construction Details

SBS | Plumbing Vent (Conventional Roof System) ( Article 12.3.2.1.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

SBS Details

1 WORK INCLUDED

- (1) Supporting Deck Overlay

- If specified and included in a Tested Assembly, an Assembly with Proven Past Performance, or a custom-engineered assembly.

- (2) Air or Vapour Control Layers

- As required by Design Authority.

- (3) Air or Vapour Control Layer Tie-in

- Illustrated to show AVB continuity with penetration.

- (4) Insulation

- Multiple layering shown (Refer to Part 7 for design, material, and installation requirements).

- (5) Insulation Overlay

- As required by the RGC Standard; see Part 8 for design, material, and installation requirements. Additionally, an overlay is required is included in a Tested Assembly, an Assembly with Proven Past Performance, or a custom-engineered assembly.

- (6) Field Base Sheet Membrane

- Selected to conform to the requirements in Table 9.2.1.1. and conforming to the options or requirements in a Tested Assembly, an Assembly with Proven Past Performance, or a custom-engineered assembly.

- (7) Penetration Flashing

- Purpose-made non-ferrous plumbing vent flashing with separate settlement cap (Item 11), sized to fit the penetration, bedded in a membrane-compatible mastic, and installed with screw fasteners. Aluminum flashings are required for torch-applied roof systems.

- (8) Membrane Target Patch

- Sized to extend at least 101.6 mm (4”) past the edge of the penetration flashing flange and sealed to the field membrane and primed flange.

- (9) Field Cap Sheet Membrane

- Selected to conform to the requirements in Membrane Composition, Thickness, and Selection Table 9.2.1.1. and conforming to the options or requirements in a Tested Assembly, an Assembly with Proven Past Performance, or a custom-engineered assembly.

- (10) Mastic

- Applied to edge of membrane and immediately covered with granules (not shown).

- (11) Settlement Cap

- Sized to fit both inside the penetration pipe (to direct rainwater into the penetration) and outside the flashing (a snug fit, secured with a screw, is required to keep the cap in place).

Optional: Vandal-proof cap (not shown).

- (12) EPDM Membrane Wrap (Optional)

- Used when the plumbing pipe cannot be cut down to fit inside the flashing (Refer to Article 12.3.2.1., Sentence (16)).

- (13) Flashing Insulation

- Factory-applied for insulated flashings, used where condensation between the pipe and the flashing is possible.

2 RELATED WORK BY OTHERS

- (A) Supporting (Structural) Roof Deck

- Steel deck illustrated.

- (B) Plumbing Penetration

- Extend to match top of metal flashing.

NOTE: See the Standard for additional requirements.

Back to "SBS" Roof System Details

© RCABC 2025

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.