Materials:(M. Kirk) FF100 Snap Lock

Materials:(M. Kirk) FF100 Snap Lock

Division C - Accepted Materials

SS675 Mechanical Lock

by Mack Kirk Roofing & Sheet Metal Ltd.

| The metal panel listed and described below is accepted for use in the RoofStar Guarantee Program. |

The roofing assembly / material information published below and in the RCABC Roofing Practices Manual DOES NOT represent a complete set of the manufacturer's published data, nor does it represent a detailed specification. The preparation of a detailed specification is the responsibility of the design authority. For more information about this product or system, consult the manufacturer. |

OVERVIEW

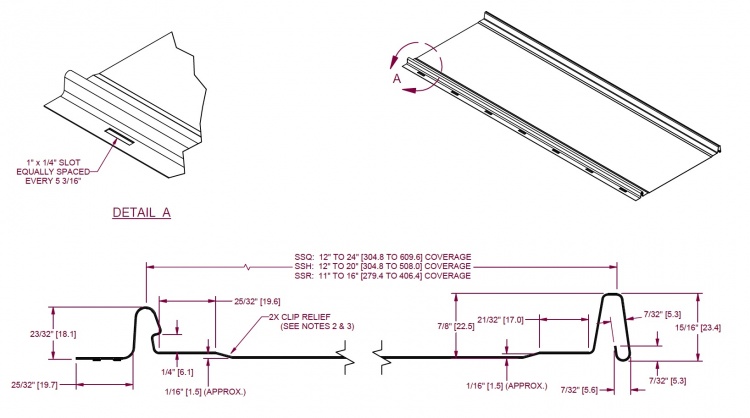

The New Tech SSQ2 is an on-site continuous panel metal roofing machine. Panel profiles vary from 300 mm (12") to 610 mm (24") wide; stiffening ribs are standard.

On-site roll forming provides for the elimination of end laps with continuous panel forming capabilities in lengths up to nominal 29 m (95').

SYSTEM DESCRIPTION

- General: The MK FF100 Snap Lock is a mechanically locking, concealed fastener roofing panel, secured with independent standing clips. The panel can be formed in any width between 300 mm (12") to 610 mm (24"). The male leg locks along the entire length of the panel and does not rely upon clips to provide additional locking.

- Range of application: on wood or metal sloped roofs; in commercial, institutional, industrial and residential construction; for re-roofing or new construction.

- Fabrication:

- Unless otherwise shown on drawings or specified herein, fabricate panels in continuous one piece lengths and fabricate flashings and accessories in longest practical lengths.

- Roofing panels shall be factory formed or site formed.

- Verify prior to fabrication.

- If field measurements differ from drawing dimensions, notify Architect / Professional Engineer prior to fabrication.

- Fasteners (Screws): Fasteners used to attach panel clips to steel to be No. 10 - 12 by 25 mm (1") long pancake head wood screws. Minimum two fasteners per clip to be used.

- Panel Clips: Two piece assembly, consisting of a steel base (length and width unspecified, subject to engineering requirements), minimum thickness 0.036" (No. 20 MSG), and an upper tab (length and width unspecified, subject to engineering requirements), minimum thickness 0.020" (No. 26 MSG). Spacing of clips is subject to engineering requirements.

- Deck Requirements: in keeping with the Standard for Architectural Sheet Metal (ASM) Systems.

PROFILE

| MK FF100 Snap Lock Panel |

|---|

|

TECHNICAL DATA SHEET

Click below for the Technical Data Sheet

SITE CONDITIONS

- Minimum roof slope is 1:4 (3" in 12"). Severe conditions (heavy snow or ice) minimum slope is 1:1.5 (8" in 12").

PERFORMANCE REQUIREMENTS

- Wind Uplift Resistance: Panel securement shall conform to the requirements in Part 3 of the Standard for Architectural Sheet Metal (ASM) Systems.

- Materials:RoofStar (RGC) accepted metal panel systems shall be formed of steel conforming to the requirements published in Section 9.2. of the Standard.