Difference between revisions of "Materials:(Nielsen) SS 100"

Difference between revisions of "Materials:(Nielsen) SS 100"

(→PROFILE) |

|||

| Line 35: | Line 35: | ||

| [[File:Nielsen_SS_100_Profile.jpg|frameless|link=http://rpm.rcabc.org/images/c/ca/Nielsen_SS_100_Profile.jpg|750px]] | | [[File:Nielsen_SS_100_Profile.jpg|frameless|link=http://rpm.rcabc.org/images/c/ca/Nielsen_SS_100_Profile.jpg|750px]] | ||

|} | |} | ||

| + | |||

| + | :Click below for the manufacturer's panel profile sheet. | ||

| + | |||

| + | <div style="width:150px; text-align: left;"> | ||

| + | :[[File:Pdf.png|75 px|link=http://rpm.rcabc.org/images/7/74/Lam_Metals_SS_200_Panel_Profile_sheet.pdf|'''Panel Profile sheet''']] | ||

| + | </div> | ||

| + | |||

====TECHNICAL DATA SHEET==== | ====TECHNICAL DATA SHEET==== | ||

N/A | N/A | ||

Revision as of 22:01, 4 February 2021

| The metal panel listed and described below is accepted for use in the RoofStar Guarantee Program. |

The roofing assembly / material information published below and in the RCABC Roofing Practices Manual DOES NOT represent a complete set of the manufacturer's published data, nor does it represent a detailed specification. The preparation of a detailed specification is the responsibility of the design authority. For more information about this product or system, consult the manufacturer. |

OVERVIEW

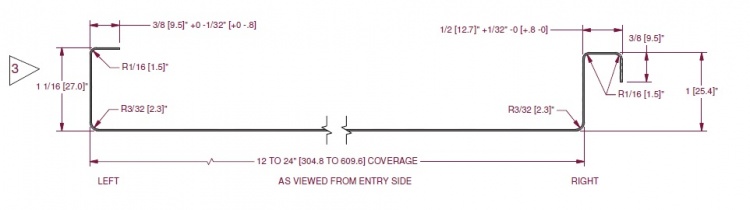

The New Tech Machinery Panel Machine is an on-site continuous metal roofing panel roll forming machine. This machine produces Standing Seam - SS 100 with a seam height of 23.4 mm (15/16"). The panel profile varies from 305 mm (12") to 610 mm (24") wide.

On-site roll forming provides for the elimination of end laps with continuous panel forming capabilities in lengths up to nominal 46m (150').

SYSTEM DESCRIPTION

- General: Metal panels employ a hidden fastening system for securement to a solid substrate. 1" Snap-Lock panels are produced with a nail strip to eliminate the use of clips and allows the panel seams to interlock without having to use a mechanical seaming device.

- Range of application: on wood or metal sloped roofs; in commercial, institutional, industrial and residential applications; for re-roofing or new construction.

- Fasteners (Screws): used to attach to plywood to be #10-12 x 25mm (1") long, pancake head, No. 2 Phillips or Robertson drive, A-point, coated steel screw. Fasteners to be spaced min. 610 mm (24") on centre fastened to plywood deck.

- Deck Requirements: in keeping with the RoofStar Guarantee Standards for ASM Systems.

PROFILE

| SS 100 Standing Seam Panel |

|---|

|

- Click below for the manufacturer's panel profile sheet.

TECHNICAL DATA SHEET

N/A

SITE CONDITIONS

- Minimum roof slope is 1:4 (3" in 12"). Severe conditions (heavy snow or ice) minimum slope is 1:2.5 (8" in 12").

PERFORMANCE REQUIREMENTS

- Wind Uplift Standards: Engineered designs to resist wind uplift may refer to the British Columbia Building Code, Div. B, Appendix C, Table C-2 which lists various types of loads, including wind loads, for specific reference locations throughout the province. See also Guides and Notes (Wind Resistance) for a simplified calculation procedure. Regardless of the resources indicated here, the Design Authority is responsible to perform accurate wind load calculations and specify securement requirements.

- Materials:RoofStar (RGC) accepted metal panel systems shall be formed of steel conforming to the standards published in the RoofStar Guarantee Standards for ASM Systems.