Difference between revisions of "Requirements"

Difference between revisions of "Requirements"

(→Hot Works: {{hilite | Design || 2021-February-7 }}) |

(→Contractor Qualifications for Roof and Grade-level Waterproofing) |

||

| (15 intermediate revisions by the same user not shown) | |||

| Line 7: | Line 7: | ||

<div class="col-md-9" id="mainBodyDiv"> | <div class="col-md-9" id="mainBodyDiv"> | ||

| − | == | + | =General= |

| + | |||

| + | ==Definitions== | ||

| + | <ol> | ||

| + | <li>Words that appear in italics are defined in the [http://rpm.rcabc.org/index.php?title=Glossary '''Glossary'''] in this ''Manual''. | ||

| + | </li></ol> | ||

| + | |||

| + | ==All Guarantees== | ||

| + | <ol> | ||

| + | <li>The requirements in this Part apply to all Standards for all ''projects'' unless expressly varied by the ''Guarantor'' under the terms of the Guarantee issued for a ''project''. | ||

| + | </li></ol> | ||

| + | |||

| + | ==RoofStar 15-Year Guarantee== | ||

<ol> | <ol> | ||

| − | <li>The requirements | + | <li>The requirements for a '''''RoofStar 15-year Guarantee''''' shall be as described in Part 1 of the governing Standard located in Division D, Division E or Division F. |

</li></ol> | </li></ol> | ||

| − | + | =Hot Works= | |

| + | ==Design== | ||

<span class="reference">When any portion of a waterproofing system is installed with heat, the work is classified as Hot Work. Some tools used in the course of Hot Work can ignite combustible materials, and some building environments are more sensitive to fire than others, such as a building containing, or close to, flammable liquids. Hot work may occur during</span> | <span class="reference">When any portion of a waterproofing system is installed with heat, the work is classified as Hot Work. Some tools used in the course of Hot Work can ignite combustible materials, and some building environments are more sensitive to fire than others, such as a building containing, or close to, flammable liquids. Hot work may occur during</span> | ||

:*<span class="reference">tear off (sparks)</span>. | :*<span class="reference">tear off (sparks)</span>. | ||

| Line 21: | Line 34: | ||

<ol> | <ol> | ||

<li><span class="recommended">{{hilite | The ''Design Authority'' may specify that the contractor must maintain compliance with the RCABC Hot Work Program and consequently manage the Hot Work conducted on site || 2020-October-22 }}</span>. | <li><span class="recommended">{{hilite | The ''Design Authority'' may specify that the contractor must maintain compliance with the RCABC Hot Work Program and consequently manage the Hot Work conducted on site || 2020-October-22 }}</span>. | ||

| − | <li>{{hilite | When the project involves Hot Work, the ''Design Authority'' must either || 2020-October-22 }} | + | <li>{{hilite | When the ''project'' involves Hot Work, the ''Design Authority'' must either || 2020-October-22 }} |

<ol> | <ol> | ||

<li>{{hilite | pre-approve alternate applications already written within the RPM, when the specified application is deemed to be fire sensitive by the contractor as part of the risk assessment process || 2020-October-22 }}. | <li>{{hilite | pre-approve alternate applications already written within the RPM, when the specified application is deemed to be fire sensitive by the contractor as part of the risk assessment process || 2020-October-22 }}. | ||

| − | <li>{{hilite | provide alternate material and application requirements in the Specification for fire sensitive locations on the '' | + | <li>{{hilite | provide alternate material and application requirements in the Specification for fire sensitive locations on the ''project'' || 2020-October-22 }}. |

</li></ol> | </li></ol> | ||

</li></ol> | </li></ol> | ||

| − | |||

| − | |||

| − | == | + | ==Contractor Requirements== |

<ol> | <ol> | ||

| − | <li>The Contractor must maintain the requirements of the RCABC Hot Work Program. This includes the following, without limitation: | + | <li>The ''Contractor'' must maintain the requirements of the RCABC Hot Work Program. This includes the following, without limitation: |

<ol> | <ol> | ||

<li>'''Insurance Coverage''' – limits carried on the ''Contractor’s'' policy must equal or exceed the minimum requirements set by RCABC, and coverage must be unhindered by warranties that limit or exclude coverage when Hot Work is required. | <li>'''Insurance Coverage''' – limits carried on the ''Contractor’s'' policy must equal or exceed the minimum requirements set by RCABC, and coverage must be unhindered by warranties that limit or exclude coverage when Hot Work is required. | ||

<li>'''Education and training''' – workers who perform hot work must be trained by the ''Contractor'' and kept current with acceptable methods. | <li>'''Education and training''' – workers who perform hot work must be trained by the ''Contractor'' and kept current with acceptable methods. | ||

<li>'''British Columbia Fire Code''' – a Fire Safety Plan, preventative methods or alternative work procedures, fire watches, and the use and placement of equipment at the Project site must comply with the BC Fire Code requirements for Hot Work. | <li>'''British Columbia Fire Code''' – a Fire Safety Plan, preventative methods or alternative work procedures, fire watches, and the use and placement of equipment at the Project site must comply with the BC Fire Code requirements for Hot Work. | ||

| − | <li>'''Fire Safety Plan''' – the ''Contractor'' must assess the hazards to property and persons and produce a written Fire Safety Plan prior to the start of work. The Fire Safety Plan must be kept on the '' | + | <li>'''Fire Safety Plan''' – the ''Contractor'' must assess the hazards to property and persons and produce a written Fire Safety Plan prior to the start of work. The Fire Safety Plan must be kept on the ''project'' site and must be kept current until the ''Project'' is completed. |

| − | <li>'''RoofStar Guarantee Standards''' – the Contractor must adhere to the '''''RoofStar Guarantee Standards''''' at each juncture where the interface of different membranes applications constitutes part of the Fire Safety Plan. | + | <li>'''RoofStar Guarantee Standards''' – the ''Contractor'' must adhere to the '''''RoofStar Guarantee Standards''''' at each juncture where the interface of different membranes applications constitutes part of the Fire Safety Plan. |

<li>'''Fire Watch''' – the ''Contractor'' must, as part of the Fire Safety Plan, conduct a fire watch | <li>'''Fire Watch''' – the ''Contractor'' must, as part of the Fire Safety Plan, conduct a fire watch | ||

<ol> | <ol> | ||

| Line 45: | Line 56: | ||

<li>documented in a written fire watch log. | <li>documented in a written fire watch log. | ||

</li></ol> | </li></ol> | ||

| − | <li>'''Hot Work Notification''' – notify the '' | + | <li>'''Hot Work Notification''' – notify the ''project'' authority or the AHJ, as and when required, that Hot Works will be performed. |

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | =Workmanship= | ||

| + | ==General Requirements== | ||

| + | <ol> | ||

| + | <li>While integrity and functionality of a new roof or waterproofed ''deck'' is the foundation of a '''''RoofStar Guarantee''''', it is no less important to ensure that the finished ''Project'' exhibits excellent workmanship. {{hilite | Therefore, the following Standards apply|| 2021-February-7 }}: | ||

| + | <ol> | ||

| + | <li>{{hilite | The ''Contractor'' must take reasonable measures to protect the ''Project'' from damage by the weather, during and at the completion of construction. Open penetrations and flashings must be temporarily sealed off from the weather, even when other trades are responsible to make a permanent seal or install overlapping materials. See also '''4.1 General''' || 2021-February-7 }}. | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | ==Contractor Qualifications for Roof and Grade-level Waterproofing== | ||

| + | <ol> | ||

| + | <li>Supervision and installation of a RoofStar-guaranteed ''Waterproofing System'' may be conducted only by established employees of ''Contractors'', and every ''project'' must be supervised by a Journeyperson employee who holds a valid ticket. In keeping with RCABC Membership policy, a Journeyperson may supervise a maximum of three (3) apprentices and/or three (3) labourers (ref. RCABC Policy A-248, Current Ed.). | ||

| + | </li></ol> | ||

| + | |||

| + | ==Contractor Qualifications for Architectural Sheet Metal Roof Systems== | ||

| + | <ol> | ||

| + | <li>Supervision, manufacturing and installation of a RoofStar-guaranteed Architectural Sheet Metal Roof System may be conducted only by established employees of ''Contractors'' who possess at least one of the following valid qualifications: | ||

| + | <ol> | ||

| + | <li>Architectural Sheet Metal Journeyperson Certificate of Qualification. | ||

| + | <li>Sheet Metal trade ticket, together with at least five (5) years of documented experience installing and supervising the installation of ASM roofing. | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | =Integrity Scanning and Electronic Leak Detection= | ||

| + | <span class="reference">An integrity scan is performed after the installation of the waterproofing ''roof system'', before any ''Overburden'', equipment or amenity space is installed on top of it. An integrity scan typically uses low-voltage electrical current to detect even the smallest breaches in the roof membrane, but some waterproofing materials may require the use of other technologies to verify the roof system’s integrity.</span> <span class="principles">Therefore, ''Design Authority'' should specify the appropriate technology, keeping in mind the limitations of each scan and detection methodology, and of the membranes that are specified.</span> | ||

| + | |||

| + | <span class="reference">Electronic Leak Detection (ELD) utilizes low-voltage electrical current, typically conducted through wires installed in a grid pattern, and are used in response to a leak, to isolate its location in order to minimize investigation time and material removal. This can benefit a building owner who will have to bear the costs of demolition or overburden removal when the standard limits of coverage afforded by the</span> '''''RoofStar Guarantee''''' <span class="reference">are exceeded by the ''Project'' design and construction. ELDs may be passive (installed but not monitored) or actively monitored (by the installer, through real-time data collection)</span>. | ||

| + | <ol> | ||

| + | <li><span class="recommended">Flood testing (as an alternative to an integrity scan) is not recommended</span>. When flood testing is specified, testing shall be conducted prior to installation of insulation and roof coverings, and must be performed to ''ASTM D5957''. | ||

| + | <li>Neither an integrity scan nor an Electronic Leak Detection (ELD) system are considered Accepted Materials, but firms that provide these services are nevertheless specifically recognized and approved by the '''''RoofStar Guarantee Program'''''. | ||

| + | <li>An integrity scan is required for some ''Projects'' (see '''1.6 RoofStar Guarantee: Coverage and Limitations'''), <span class="recommended">but is nevertheless strongly recommended before the completed ''roof assembly'' is covered with ''Overburden'', equipment or living (amenity) spaces</span> (see '''14.1.2.1'''). | ||

| + | <ol> | ||

| + | <li><span class="recommended">for ''Projects'' where multiple trades will have access to a roof that is under construction and completed, in order to identify breaches in the waterproofing membrane in a timely way and avoid future costly delays</span>. | ||

| + | <li><span class="recommended">when the ''roof assembly'' protects a sensitive occupied space (i.e. data centres, hospitals, critical infrastructure)</span>. | ||

| + | <li><span class="recommended">when the roof supports any type of ''Overburden'', equipment or living (amenity) space</span>. | ||

| + | </li></ol> | ||

| + | <li> <span class="principles">When Electronic Leak Detection is specified, it should provide detection capabilities for all waterproofed surfaces, and should extend at least 50 mm (2") vertically from the water plane at</span> | ||

| + | <ol> | ||

| + | <li> <span class="principles">all transitions</span>. | ||

| + | <li> <span class="principles">any point along the entire deck perimeter</span>. | ||

| + | <li> <span class="principles">protrusions</span>. | ||

</li></ol> | </li></ol> | ||

</li></ol> | </li></ol> | ||

| − | = | + | =Variances= |

| − | + | When a design is unable to conform to the Standard, the ''Design Authority'' may apply to the RGC for a written Variance. Application must be made in writing (email correspondence is common), and the request must | |

<ol> | <ol> | ||

| − | <li> | + | <li>identify the ''project'' name, its civic address and the applicable '''''RoofStar Guarantee''''' number (if already initiated). |

| − | <li> | + | <li>articulate the nature of the design problem. |

| − | <li> | + | <li>cite the '''''RoofStar Guarantee''''' standard reference to which the Variance will apply. |

| − | <li> | + | <li>provide design drawings (and photographs, if available) as supporting information. |

</li></ol> | </li></ol> | ||

| − | + | We may ask for more information in order to fully consider a request for a Variance and will issue a completed Variance only to the ''Design Authority'' for distribution to the ''Contractor''. | |

| − | + | A Variance may be unrestricted in its scope, or it may include one or more conditions that will affect the design and construction of the ''Water-shedding System'' or ''Waterproofing System'', in order to accommodate the varied Standard. Occasionally, a Variance may also restrict coverage offered by the '''''RoofStar Guarantee'''''. | |

| − | + | Variances are issued only for the specific issue on the ''project'' identified in the written request, and do not constitute general permission to depart from the published Standards in this ''Manual'', for any aspect of the same ''project'' or for future ''projects'', designed or constructed by any other firm. | |

| − | + | ={{hilite | Guarantee Coverage and Limitations || 2020-July-3 }}= | |

| − | The following governs all Standards published for | + | The following governs all Standards published for ''waterproofing'' or ''water-shedding systems''. |

{{Template:Section 1.6 (All Standards)}} | {{Template:Section 1.6 (All Standards)}} | ||

Latest revision as of 22:03, 3 May 2021

1 General

1.1 Definitions

- Words that appear in italics are defined in the Glossary in this Manual.

1.2 All Guarantees

- The requirements in this Part apply to all Standards for all projects unless expressly varied by the Guarantor under the terms of the Guarantee issued for a project.

1.3 RoofStar 15-Year Guarantee

- The requirements for a RoofStar 15-year Guarantee shall be as described in Part 1 of the governing Standard located in Division D, Division E or Division F.

2 Hot Works

2.1 Design

When any portion of a waterproofing system is installed with heat, the work is classified as Hot Work. Some tools used in the course of Hot Work can ignite combustible materials, and some building environments are more sensitive to fire than others, such as a building containing, or close to, flammable liquids. Hot work may occur during

- tear off (sparks).

- deck preparation (drying wet surfaces).

- cold temperatures (warming materials or surfaces).

- equipment use (sparks within electrical tools, or from cutting, drilling or grinding metal, concrete, stone or other hard surface products).

- The Design Authority may specify that the contractor must maintain compliance with the RCABC Hot Work Program and consequently manage the Hot Work conducted on site.

- When the project involves Hot Work, the Design Authority must either

- pre-approve alternate applications already written within the RPM, when the specified application is deemed to be fire sensitive by the contractor as part of the risk assessment process.

- provide alternate material and application requirements in the Specification for fire sensitive locations on the project.

2.2 Contractor Requirements

- The Contractor must maintain the requirements of the RCABC Hot Work Program. This includes the following, without limitation:

- Insurance Coverage – limits carried on the Contractor’s policy must equal or exceed the minimum requirements set by RCABC, and coverage must be unhindered by warranties that limit or exclude coverage when Hot Work is required.

- Education and training – workers who perform hot work must be trained by the Contractor and kept current with acceptable methods.

- British Columbia Fire Code – a Fire Safety Plan, preventative methods or alternative work procedures, fire watches, and the use and placement of equipment at the Project site must comply with the BC Fire Code requirements for Hot Work.

- Fire Safety Plan – the Contractor must assess the hazards to property and persons and produce a written Fire Safety Plan prior to the start of work. The Fire Safety Plan must be kept on the project site and must be kept current until the Project is completed.

- RoofStar Guarantee Standards – the Contractor must adhere to the RoofStar Guarantee Standards at each juncture where the interface of different membranes applications constitutes part of the Fire Safety Plan.

- Fire Watch – the Contractor must, as part of the Fire Safety Plan, conduct a fire watch

- that complies with the British Columbia Fire Code.

- assigned to competent, trained personnel using suitable equipment, including the use of a hand-held infrared thermometer.

- documented in a written fire watch log.

- Hot Work Notification – notify the project authority or the AHJ, as and when required, that Hot Works will be performed.

3 Workmanship

3.1 General Requirements

- While integrity and functionality of a new roof or waterproofed deck is the foundation of a RoofStar Guarantee, it is no less important to ensure that the finished Project exhibits excellent workmanship. Therefore, the following Standards apply:

- The Contractor must take reasonable measures to protect the Project from damage by the weather, during and at the completion of construction. Open penetrations and flashings must be temporarily sealed off from the weather, even when other trades are responsible to make a permanent seal or install overlapping materials. See also 4.1 General.

3.2 Contractor Qualifications for Roof and Grade-level Waterproofing

- Supervision and installation of a RoofStar-guaranteed Waterproofing System may be conducted only by established employees of Contractors, and every project must be supervised by a Journeyperson employee who holds a valid ticket. In keeping with RCABC Membership policy, a Journeyperson may supervise a maximum of three (3) apprentices and/or three (3) labourers (ref. RCABC Policy A-248, Current Ed.).

3.3 Contractor Qualifications for Architectural Sheet Metal Roof Systems

- Supervision, manufacturing and installation of a RoofStar-guaranteed Architectural Sheet Metal Roof System may be conducted only by established employees of Contractors who possess at least one of the following valid qualifications:

- Architectural Sheet Metal Journeyperson Certificate of Qualification.

- Sheet Metal trade ticket, together with at least five (5) years of documented experience installing and supervising the installation of ASM roofing.

4 Integrity Scanning and Electronic Leak Detection

An integrity scan is performed after the installation of the waterproofing roof system, before any Overburden, equipment or amenity space is installed on top of it. An integrity scan typically uses low-voltage electrical current to detect even the smallest breaches in the roof membrane, but some waterproofing materials may require the use of other technologies to verify the roof system’s integrity. Therefore, Design Authority should specify the appropriate technology, keeping in mind the limitations of each scan and detection methodology, and of the membranes that are specified.

Electronic Leak Detection (ELD) utilizes low-voltage electrical current, typically conducted through wires installed in a grid pattern, and are used in response to a leak, to isolate its location in order to minimize investigation time and material removal. This can benefit a building owner who will have to bear the costs of demolition or overburden removal when the standard limits of coverage afforded by the RoofStar Guarantee are exceeded by the Project design and construction. ELDs may be passive (installed but not monitored) or actively monitored (by the installer, through real-time data collection).

- Flood testing (as an alternative to an integrity scan) is not recommended. When flood testing is specified, testing shall be conducted prior to installation of insulation and roof coverings, and must be performed to ASTM D5957.

- Neither an integrity scan nor an Electronic Leak Detection (ELD) system are considered Accepted Materials, but firms that provide these services are nevertheless specifically recognized and approved by the RoofStar Guarantee Program.

- An integrity scan is required for some Projects (see 1.6 RoofStar Guarantee: Coverage and Limitations), but is nevertheless strongly recommended before the completed roof assembly is covered with Overburden, equipment or living (amenity) spaces (see 14.1.2.1).

- for Projects where multiple trades will have access to a roof that is under construction and completed, in order to identify breaches in the waterproofing membrane in a timely way and avoid future costly delays.

- when the roof assembly protects a sensitive occupied space (i.e. data centres, hospitals, critical infrastructure).

- when the roof supports any type of Overburden, equipment or living (amenity) space.

- When Electronic Leak Detection is specified, it should provide detection capabilities for all waterproofed surfaces, and should extend at least 50 mm (2") vertically from the water plane at

- all transitions.

- any point along the entire deck perimeter.

- protrusions.

5 Variances

When a design is unable to conform to the Standard, the Design Authority may apply to the RGC for a written Variance. Application must be made in writing (email correspondence is common), and the request must

- identify the project name, its civic address and the applicable RoofStar Guarantee number (if already initiated).

- articulate the nature of the design problem.

- cite the RoofStar Guarantee standard reference to which the Variance will apply.

- provide design drawings (and photographs, if available) as supporting information.

We may ask for more information in order to fully consider a request for a Variance and will issue a completed Variance only to the Design Authority for distribution to the Contractor.

A Variance may be unrestricted in its scope, or it may include one or more conditions that will affect the design and construction of the Water-shedding System or Waterproofing System, in order to accommodate the varied Standard. Occasionally, a Variance may also restrict coverage offered by the RoofStar Guarantee.

Variances are issued only for the specific issue on the project identified in the written request, and do not constitute general permission to depart from the published Standards in this Manual, for any aspect of the same project or for future projects, designed or constructed by any other firm.

6 Guarantee Coverage and Limitations

The following governs all Standards published for waterproofing or water-shedding systems.

A RoofStar Guarantee is available for almost any roof design, provided its design and construction conforms to the requirements published in the RGC Standards. Nevertheless, there are limitations and conditions. They are listed on the Guarantee Certificate, and include (without limitation) the following (as they are applicable to the type of project):

- The RoofStar Guarantee covers leaks resulting from new materials purchased, supplied and installed by the Contractor. All new materials incorporated into a Project intended to qualify for a RoofStar Guarantee must be expressly accepted by the RGC and listed in the Roofing Practices Manual. Accepted Materials include (without limitation)

- Primary and Secondary Materials.

- penetration flashings and drains.

- roof-related linear metal flashings.

All materials or products supplied by anyone other than an Associate Member of the RCABC, or which are installed by someone other than the Contractor, will be excluded from coverage under the Guarantee, and may void the Guarantee entirely.

- Notwithstanding the definition of a waterproofing system or water-shedding system, the RoofStar Guarantee does not cover the quality, installation or performance of the supporting deck.

- The RoofStar Guarantee (subject to the limitations described herein or stated on the Guarantee certificate) is a guarantee against leaks only, caused only by a failure of new materials installed by the Contractor, or resulting from the Contractor 's installation of new materials.

The term "new materials" includes Primary and Secondary Materials, linear metal flashings, and both penetration flashings and roof drains that have been expressly accepted for use on a project designed and constructed to qualify for a RoofStar Guarantee. Only materials listed in the Accepted Materials Division of the Roofing Practices Manual qualify for a RoofStar Guarantee.

The re-use of any existing material on a project may void the Guarantee. - Notwithstanding any of the Guarantee requirements in this Manual, a RoofStar Guarantee will not cover

- leaks resulting from

- improper design.

- overloading.

- water entry from other building components (walls, skylights, etc.).

- the failure of a drain or flashing supplied or installed by anyone other than the Contractor.

- neglected maintenance of the project.

- building air leakage, or the use or absence of air or vapour controls.

- modifications to the project made by anyone other than the Contractor.

- changes in building use or occupancy.

- drain leaders, which are not considered part of the roof system.

- the costs to remove and reinstall irrigation or other services (including, without limitation, electrical and gas services).

- replacement (new for old) of any overburden.

- damage or leaks caused by the roots of invasive plant species (for example, certain varieties of bamboo or willow), regardless of measures taken to protect the membrane.

- a sacrificial third ply or a coating, used as a walkway or warning zone, which is not considered part of the roof system.

- leaks resulting from

- Overburdens may be installed on a Conventionally Insulated waterproofing system or Protected (“inverted”) Membrane Roof Assembly, but not all designs are suitable for any type, size or depth of overburden (see Part 14 THE ROOF as a PLATFORM). The RGC recommends that a roof supporting overburden be designed and constructed as a Protected Membrane Roof Assembly. The RoofStar Guarantee may be void if a roof is designed and constructed with Overburden that exceeds the capabilities of a Conventionally Insulated waterproofing system.

- Only a fully adhered membrane may be used in a Protected (“inverted”) Membrane Roof Assembly.

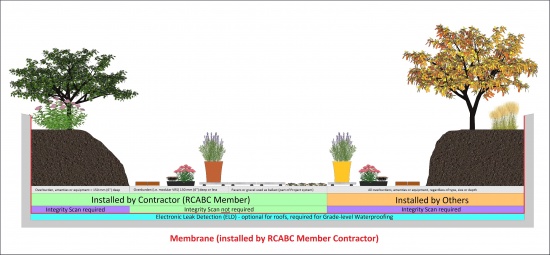

- An Integrity Scan

- must be performed by an RGC-recognized service provider listed in this Manual.

- is required on all Waterproofing Systems, to ensure the waterproofing is leak and damage-free, when overburdens, amenities or equipment are or will be installed on the completed Waterproofing System by

- anyone other than the Contractor.

- the Contractor but only when

- the total project area (footprint), inclusive of planters or other waterproofed features, exceeds 18.58 m2 (200 sf), and

- the overburdens, amenities or equipment exceed 150 mm (6”) in depth.

- is not required when the Contractor installs overburden, amenities or equipment

- equal to or less than 150 mm (6”) in depth.

- the total project area (footprint), inclusive of planters or other waterproofed features, is less than 18.58 m2 (200 sf), but the Contractor must nevertheless protect all membrane-covered surfaces (including walls and parapets) with RoofStar-accepted protection materials immediately after the membrane is installed.

See Figure 1.1 for further reference.Figure 1.1 (Click to expand)

- Electronic Leak Detection is mandatory for grade-level Waterproofing Systems, but optional for roof Waterproofing Systems.

- Pre-curbs and Concrete Features:

- When concrete walls or structures are constructed without a pre-curb, all concrete surfaces must be fully and continuously enveloped with the primary roof membrane.

- While the application of non‐penetrating bonded tiling or other architectural finishes to the waterproofing membrane is acceptable for a RoofStar Guarantee, and is subject to approval by the membrane manufacturer, the removal, reinstallation or replacement of any bonded finish, in order to investigate and repair leaks under the terms of the Guarantee, is the responsibility of others.

- Modifications during the Guarantee Term:

- The Guarantor must be notified in writing of any modifications or repairs to the RoofStar-guaranteed project.

- The Owner must ensure that any modification or repair work done on the project during the guarantee period is performed to RoofStar Guarantee Standards by a Contractor, and is inspected by a RoofStar-accepted observation firm.

- Maintenance: the building owner must ensure that the project and its components are properly maintained. Debris in drains, caulking on or around metal flashings, and wind scouring of gravel are considered maintenance issues.

- Removal and Reinstallation of Overburdens: in order to investigate and repair a leak, the RoofStar Guarantee Program must be allowed to remove overburdens, to expose the membrane. The RoofStar Guarantee pays for the removal and reinstallation of accessible overburdens only (subject to the limits published below), when they are installed by the Contractor, regardless of the project design. The cost to remove, care for and reinstall any overburden that exceeds these limits or conditions, which is inaccessible, or which was supplied or installed by others, will be borne by the building owner.

- Maximum coverage area: limited to one physically defined project area (no maximum size)

- The RoofStar Guarantee pays for removal and reinstallation of accessible overburdens up to the following limits:

- Extensive vegetated roof systems, provided they are comprised of trays or other recognized modular methods and are less than 150 mm (6”) in depth, exclusive of the plants.

- other accessible coverings, provided they are unitized (for example, pavers on pedestals) and do not exceed 1 M2 or 90 Kg (200 lb.) per unit.

- gravel ballast and its associated drainage or protection material components, provided the ballast is less than 150 mm (6”) deep.

- structures, furnishings or planters provided each item, or any single component of each item, is easily detachable, does not require a specialty trade, and is no heavier than 90 Kg (200 lb).

© RCABC 2021

No reproduction of this Manual, in whole or in part, is lawful without the expressed permission of the RGC Guarantee Program.