Difference between revisions of "AS Details:E2.7.11 (Counter-flashing - Diverter Flashing)"

Difference between revisions of "AS Details:E2.7.11 (Counter-flashing - Diverter Flashing)"

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

<hr> | <hr> | ||

[[File:7.1.5.9.jpg]] | [[File:7.1.5.9.jpg]] | ||

| − | < | + | <hr> |

Latest revision as of 22:57, 21 December 2015

WORK INCLUDED

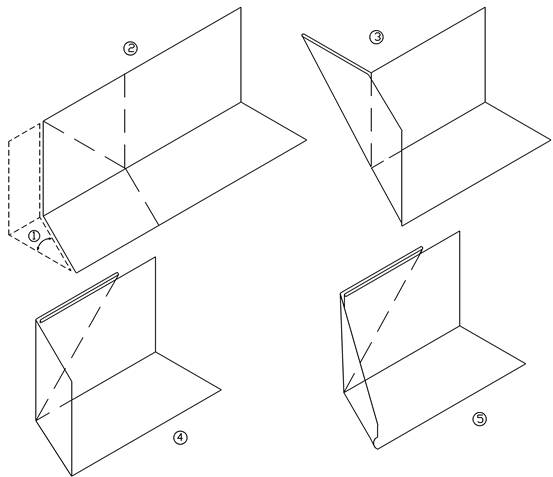

(1) Trim: and the kick-out must be approximately 20-degree angle to the vertical slope.

(2) Fold Layout: Formed from a minimum 26 guage galvanized steel diverters shall extend a minimum 125 mm (5") up vertical surfaces 100 mm (4") to the roof.

(3) Breadpanned Corner Fold: Fold up must be equal in height to to the upstand of the flashing.

(4) Hidden Seam: Breadpan fold to be turned behind the upstand.

(5) Angle Trim: Kick-out can be angle trimmed and a drip edge formed at the outlet. Outlet is to extend a minimum of 25mm (1") lower than the edge of the roof material and lead water into the gutter where existing.

- NOTE

- Refer to RGC Guarantee Standards for additional requirements

- Proprietary soldered or welded diverter flashing may be used provided they conform to RGC Guarantee Standards.

Back to Asphalt Shingle Application