Difference between revisions of "Template:Part 7 - PVC"

Difference between revisions of "Template:Part 7 - PVC"

(→Alignment, Sizing, and Support) |

|||

| Line 232: | Line 232: | ||

<ol> | <ol> | ||

<li>sloped insulation boards that are generally installed soldiered fashion to adjacent rows. | <li>sloped insulation boards that are generally installed soldiered fashion to adjacent rows. | ||

| − | <li>the first layer of overlay board, installed on top of heat-sensitive insulation, which may be soldiered to facilitate joint taping. | + | <li>the first layer of overlay board, installed on top of heat-sensitive insulation, which may be soldiered to facilitate joint taping (See also Subsection 8.3.2., ''All Systems''). |

</li></ol> | </li></ol> | ||

| − | |||

| − | |||

<br> | <br> | ||

{| class="wikitable"; table style="background-color:white"; border="#A9A9A9;" | {| class="wikitable"; table style="background-color:white"; border="#A9A9A9;" | ||

Revision as of 22:36, 15 November 2021

1 Design

1.1 General

1.1.1 Scope

- The scope of this Part and the Standard shall be as described in Part 1 of Division A in this Manual.

1.1.2 Definitions

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part:

- Heat-resistant insulation means insulation that resists heat and will not physically or chemically change when exposed to heat greater than 70°C (158°F), including heat from liquefied bitumen. Insulation boards of this type include fibreboard, polyisocyanurate and mineral wool. Note that "heat-resistant" does not mean or even infer 'fire-proof'. While some heat-resistant insulation materials will resist burning for a period of time, only mineral wool insulation will not burn.

- Heat-sensitive insulation means insulation that may be physically or chemically altered when exposed to heat greater than 70°C (158°F) - for example, heat from a torch or from liquefied bitumen. Heat-sensitive insulation includes EPS, XPS and polyurethane.

1.2 Guarantee Term Requirements

1.2.1 RoofStar 5-year and RoofStar 10-year Guarantee

- All projects intended to qualify for a RoofStar 5-year or RoofStar 10-year Guarantee shall comply with the requirements in this Part.

1.2.2 RoofStar 15-Year Guarantee

- All projects intended to qualify for a RoofStar 15-year Guarantee shall comply with the requirements in this Standard for a RoofStar 5-year or RoofStar 10-year Guarantee, together with the following:

- All curbs and sleepers that impede drainage or are wider or longer than 1200 mm (48”) must incorporate crickets to provide positive slope to drains.

1.3 All Systems

1.3.1 Responsibility for Design

(See Note A-7.1.3.1)

- The Design Authority is responsible to ensure the design conforms to the Building Code and any other applicable requirements, with respect to

- the use of a thermal barrier between the roof deck and the insulation system.

- the minimum required thermal resistance of the insulation system.

1.3.2 Effective Thermal Resistance and Layering

(See Note A-7.1.3.2)

- Consult the Code having jurisdiction for the minimum required thermal resistance of the roof system.

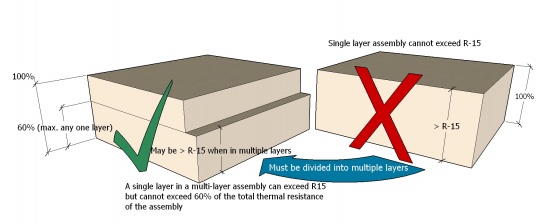

- Insulation assemblies with a cumulative thermal resistance greater than RSI-2.64 (R-15) (based on published LTTR values measured at 24°C) must be installed in multiple layers that are offset and staggered (see Section 7.3. Application).

- In a multi-layered assembly, any single layer of insulation may have a thermal resistance greater than RSI-2.64 (R-15) provided no one layer exceeds 60% of the cumulative thermal resistance of the combined assembly of insulation, measured together with the thermal resistance of insulation overlay boards (see Figure 7.1).

Figure 7.1 (Click to expand)

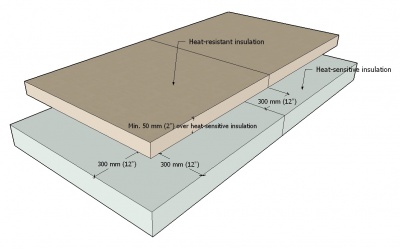

1.3.3 Protection of Heat-sensitive Insulation

- When heat-sensitive insulation is used in the primary thermal assembly, it must be covered with a heat-resistant insulation at least 50 mm (2”) thick (see also Article 7.1.3.1.).

1.3.4 Tapered Insulation and Crickets

- Tapered insulation

- may be located anywhere within the roof system (see 2.1.4. Slope).

- may be used in calculating the overall thermal performance of the insulation assembly but this is at the discretion of the Design Authority (See Note A-7.1.3.4).

- must be installed in multiple soldiered layers when the overall thickness of the tapered insulation assembly is greater than 150 mm (6”).

- that is heat-sensitive and manufactured to cover the entire roof area (commonly referred to as a full slope or taper package) must be installed beneath at least one layer of flat board heat-resistant insulation with a minimum thickness of 50 mm (2”).

- Crickets that are used only to promote drainage over limited areas of the roof (they provide no thermal resistance value to the roof system)

- should be manufactured of heat-resistant insulation, but when crickets are manufactured from heat-sensitive insulation they should be covered with a layer of heat-resistant insulation at least 50 mm (2") thick.

- may be installed directly over a roof deck, although this is not recommended See Section 8.1. Design for overlay requirements.

1.3.5 Insulating Drain Sumps

- Drain sumps should be adequately insulated for the regional location of the building, regardless of how the average thermal resistance for the roof system is calculated, to minimize condensation (See Article 11.1.2.2).

1.3.6 Use of Mineral Fibre Insulation

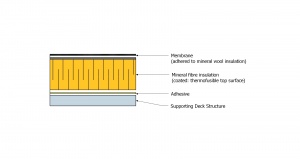

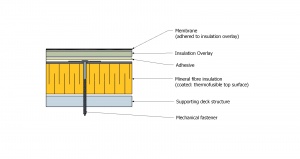

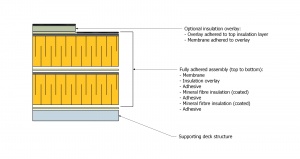

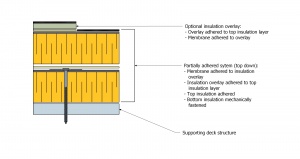

- Mineral fibre insulation panels must be secured according to both the manufacturer’s published instructions and (when applicable) the methods specified in a Tested Assembly report, but in any event their securement must conform to the following RoofStar Guarantee requirements:

- Only bitumen-coated mineral fibre insulation

- may be secured with adhesive or directly secured with screw-type fasteners and plates.

- shall be permitted as the top layer of insulation in a multi-layered insulation assembly.

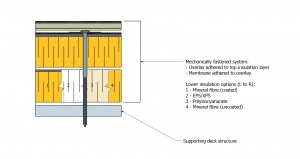

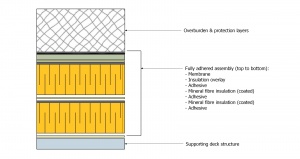

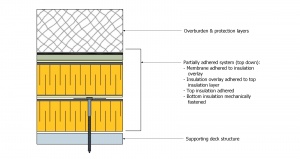

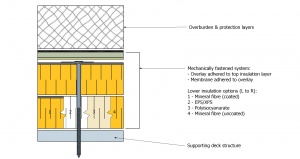

- Uncoated mineral fibre insulation panels must be used only in multi-layered insulation assemblies, they must be located below coated mineral fibre insulation panels, and they shall be secured only by mechanically fastening (see Figure 7.2(e)).

- Some roof assemblies that utilize mineral fibre insulation required an overlay. Refer to Part 8 for overlay requirements.

- Only bitumen-coated mineral fibre insulation

- See Figure 7.2 (a through h). Click any one to expand (MF = Mechanically Fastened; AD = Adhered; HYB = Hybrid Securement):

2 Materials

(See Division C: Accepted Materials)

2.1 Material Properties

2.1.1 General

- Only insulation boards accepted for use in the RoofStar Guarantee Program, and acceptable to the membrane manufacturer, may be used to qualify for a RoofStar Guarantee. This requirement extends to insulation used in Tested Assemblies (see Article 3.2.1.1, Substituting Materials Used in a Tested Assembly).

- All insulation types shall have a minimum compressive strength of 110 KPa (20 psi) when installed without a cover board under mechanically attached membranes.

2.1.2 Material Dimensions

- The maximum width and length of any adhered insulation panel shall be 1200 mm (4’) (see also Article 7.3.2.3).

- The maximum width and length of insulation boards installed with mechanical fasteners is limited only by the manufacturer.

- Insulation installed directly over a fluted steel deck must be thick enough to span the flutes under live loads, without risk of cracking or breakage.

- While minimal insulation panel thicknesses are permissible for some designs, the Design Authority should consider the constructability of the roof system from a material handling perspective. Therefore, when materials are by their nature breakable, the specifier should consider specifying a thicker panel.

2.2 Suitability of Insulation

2.2.1 Polyisocyanurate Insulation

- Only polyisocyanurate insulation with non-organic facers (e.g., fibreglass) are acceptable for use in the RoofStar Guarantee Program. In addition, manufacturers’ product identification labels are required for all polyisocyanurate insulation packaging and the date of manufacture must be provided on all product labels.

- Polyisocyanurate insulation, which is manufactured to various dimensions and board thicknesses, is suitable only for Conventionally Insulated Systems and may be manufactured in sloped packages, for individual crickets or for full roof area application.

2.2.2 Mineral Fibre Insulation

- Mineral fibre insulation panels, manufactured to various dimensions and board thicknesses, are suitable only for conventionally insulated systems (the material also may be manufactured in sloped packages, for individual crickets or for full roof area application).

2.2.3 Expanded Polystyrene Insulation

- Expanded polystyrene (EPS), manufactured in various flat board dimensions and as fully sloped packages or crickets, is suitable only for conventionally insulated systems.

2.2.4 Extruded Polystyrene Insulation

- Extruded polystyrene (XPS) is a closed-cell material manufactured in various board dimensions, and is mainly used in a Protected Membrane Roof Assembly. Only Extruded polystyrene insulation (conforming to CAN / CGSB-51.20-M87, Type 4) may be used on Protected Membrane Roof Assemblies. Refer to Part 9 - Field Membrane Systems, and Part 14 - The Roof as a Platform, for further requirements.

3 Application

3.1 Guarantee Term Requirements

3.1.1 RoofStar 5-year and RoofStar 10-year Guarantee

- All projects intended to qualify for a RoofStar 5-year or RoofStar 10-year Guarantee shall comply with the requirements in this Part.

3.1.2 RoofStar 15-Year Guarantees

- All projects intended to qualify for a RoofStar 15-year Guarantee shall comply with the requirements in this Standard for a RoofStar 5-year or RoofStar 10-year Guarantee, together with the following:

- All curbs and sleepers that impede drainage or are wider or longer than 1200 mm (48”) must incorporate crickets to provide positive slope to drains.

- An insulation overlay is required for all insulated systems, regardless of the insulation type, and overlays must

- be at least 6.4 mm (1/4”) thick, and

- possess a compressive strength of at least 690 kPa (100 psi).

3.2 All Systems

(the General Requirements of this Section shall be read together with the following Articles)

3.2.1 Alignment, Sizing, and Support

- Insulation boards must be firmly supported.

- Insulation boards should be square and should make firm, full contact with adjacent panels. Gaps greater than 6 mm (1/4”) around boards must be filled with expanding spray foam.

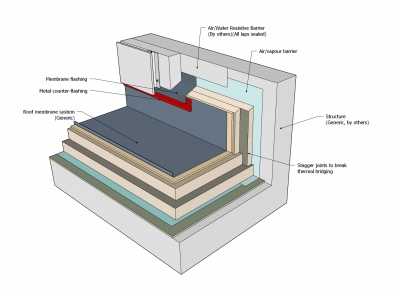

- Insulation board joints must be offset at least 300 mm (12"), both for adjacent layers and for adjacent rows; a minus offset tolerance of 50 mm (2") maximum is permissible (see Figure 7.3). Insulation offsets are not required for

- sloped insulation boards that are generally installed soldiered fashion to adjacent rows.

- the first layer of overlay board, installed on top of heat-sensitive insulation, which may be soldiered to facilitate joint taping (See also Subsection 8.3.2., All Systems).

Figure 7.3 (Click to expand)

- On exterior insulated walls, insulation joints at the roof-wall interface should be offset and staggered to eliminate thermal bridging (See Figure 7.4).

Figure 7.4 (Click to expand)

3.2.2 Insulation Securement

- Insulation must be secured to resist the Specified Wind Loads calculated for the roof system and shall conform to the specified design for the roof assembly.

3.2.3 Adhesive-applied Insulation

- Unless specified otherwise by a Tested Assembly or in an engineered specification, the following minimum standards apply to adhesive-applied insulation:

- The maximum width and length of any adhered insulation panel shall be 1200 mm (4’).

- The maximum length of any insulation overlay panel shall be 2400 mm (8’).

- When Extruded Polystyrene insulation is adhered with a two-component low-rise polyurethane foam adhesive, the faces of the insulation board must be roughened by planing to achieve optimal adhesion.

- Two-component low-rise polyurethane foam adhesive ribbons must be applied

- in parallel runs or in a Z-pattern, no more than 150 mm (6”) from any edge of the board and spaced no more than 300 mm (12”) apart.

- to a clean, dry and contaminant-free surface.

- in ribbon widths specified by the adhesive manufacturer or, in the absence of manufacturer requirements, 19 mm (3/4”) wide.

- Roof system components adhered with two-component low-rise polyurethane foam must be

- installed immediately in wet adhesive (before a surface skin develops).

- properly placed and weighted in wet adhesive until cured.

3.2.4 Insulation Adhered with Hot Bitumen

- Hot bitumen used to adhere a roof system

- must be applied at minimum rates and temperatures based on the type of product, as published by the material manufacturer and in the Standard for Built-up Roof (BUR) Systems.

- may be applied on slopes up to 1/2:12 (for steeper slopes, select a different method of securement).