Difference between revisions of "ASM Membrane Gutter (Insulated Assembly)"

Difference between revisions of "ASM Membrane Gutter (Insulated Assembly)"

(→WORK INCLUDED) |

|||

| (9 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | { | + | {{Template:RPM Info}} |

| − | + | ||

| − | + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | |

| − | + | __NOTOC__ | |

| − | + | ||

| + | <big><big>Division D - Construction Details</big></big> | ||

| + | <hr> | ||

| + | <big><big><big><big><big>ASM | Membrane Gutter (Insulated Assembly) ([[ASM_Roof_Systems_Standard#11.1.4.3.._Membrane_Gutters | Article 11.1.4.3.]] and [[ASM_Roof_Systems_Standard#11.3.3.8._Membrane_Gutters | Article 11.3.3.8.]])</big></big></big></big></big> | ||

| + | {{Template:Construction Details Header}} | ||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

<div class="panel-heading"><big>'''ASM Details'''</big></div> | <div class="panel-heading"><big>'''ASM Details'''</big></div> | ||

| Line 23: | Line 27: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[ | + | ;(1) [[ASM Roof Systems Standard#PART_5|'''Deck overlay''']]: Required for continuous support of the underlayment when the deck is not suitable. |

| − | ;(2) [[ | + | ;(2) [[ASM Roof Systems Standard#8.1.3.3. Field Underlayment|'''Underlayment (lower)''']]: The type of underlay required is determined by roof slope. |

;(3) Wood blocking | ;(3) Wood blocking | ||

| − | ;(4) '''Insulation | + | ;(4) [[ASM Roof Systems Standard#PART_7|'''Insulation''']]: Tapered to support gutter membrane, which is tied into underlayment, to ensure any water intrusion into roof system drains into gutter. |

| − | ;(5) [[ | + | ;(5) [[ASM Roof Systems Standard#11.1.4.3.. Membrane Gutters |'''Gutter Membrane''']] |

| − | ;(6) [[ | + | ;(6) [[ASM Roof Systems Standard#8.1.3.3. Field Underlayment|'''Underlayment (upper)''']] |

| − | ;(7) [[ | + | ;(7) [[ASM Roof Systems Standard#PART_7| '''Upper insulation''']]: Tapered at lower edge to conform to lower insulation slope. All flat panels must be offset and stagger layers 300 mm (12"). |

| − | ;(8) [[ | + | ;(8) [[ASM Roof Systems Standard#8.1.3.4. Separation Between Materials|'''Vapour-permeable separation membrane''']]: Installed over insulation and required on all insulated Architectural Sheet Metal Roof Systems. The material must be located between the insulation and metal panels/ventilation material (see [http://rpm.rcabc.org/index.php?title=RoofStar_Guarantee_Standards_for_Architectural_Sheet_Metal_(ASM)_Systems#Design_5 '''8.1.2 Design'''])). |

| − | ;(9) [[ | + | ;(9) [[ASM Roof Systems Standard#8.1.3.5. Ventilation Beneath Panels|'''Ventilation beneath panels''']]: Recommended over asphaltic underlays and / or as required in this Standard (see [http://rpm.rcabc.org/index.php?title=RoofStar_Guarantee_Standards_for_Architectural_Sheet_Metal_(ASM)_Systems#Design_5 '''8.1.2 Design''']). |

| − | ;(10) [[ | + | ;(10) [[ASM Roof Systems Standard#9.2.1.6. Bearing Plates and EPDM Pads|'''Bearing plate''']]: Only thermally non-conductive clips or bars passing through the insulation assembly, or mechanically fastened bearing plates, may be used to secure and support insulation panels, or provide support for panel clips. |

| − | ;(11) [[ | + | ;(11) [[ASM Roof Systems Standard#9.2.1.5.Clips |'''Architectural metal panel clip''']] |

| − | ;(12) [[ | + | ;(12) [[ASM Roof Systems Standard#PART_9 |'''Architectural metal roof panel''']]: Lower, installed prior to the pipe flashing, cut hole large enough to allow for movement. Extend 400 mm (16") upslope beyond the pipe. |

;(13) Mastic (2-ply SBS) or Sealant (Single plies): Drain flange must be embedded in a membrane-compatible mastic and secured to the gutter structure. | ;(13) Mastic (2-ply SBS) or Sealant (Single plies): Drain flange must be embedded in a membrane-compatible mastic and secured to the gutter structure. | ||

| − | ;(14) Drain | + | ;(14) [[ASM Roof Systems Standard#PART_11 |'''Drain Body''']]: Mechanically secured through flange (for all drain types, see '''Part 11 DRAINS and PENETRATIONS''' in the relevant membrane standard in this ''Manual''). |

;(15) Strainer | ;(15) Strainer | ||

| − | ;(16) Gutter | + | ;(16) [[ASM Roof Systems Standard#11.1.4.3.. Membrane Gutters |'''Gutter Membrane''']]: Refer to the relevant membrane standard for application requirements (SBS, EPDM, TPO or PVC). |

| − | ;(17) Parapet cap flashing | + | ;(17) [[ASM Roof Systems Standard#PART_13 |'''Parapet cap flashing''']] |

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[ | + | ;(A) [[ASM Roof Systems Standard#PART_2|'''Acceptable Deck''']] |

;(B) '''Built-in Gutter structure'''. Sloped to drain. | ;(B) '''Built-in Gutter structure'''. Sloped to drain. | ||

;(C) '''Parapet''' | ;(C) '''Parapet''' | ||

| Line 51: | Line 55: | ||

</div><!-- PANEL --> | </div><!-- PANEL --> | ||

| − | '''NOTE''': | + | '''NOTE''': See the [[ASM Roof Systems Standard | '''Standard''']] for additional requirements. |

<hr> | <hr> | ||

| − | [[ | + | [[ASM Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''ASM Roof System Details'']] |

| + | |||

| + | [[Main Page | <i class="fa fa-home fa"></i> Home]] | ||

| − | + | {{Tempate:RPM Page Footer with Copyright and Current Date}} | |

Latest revision as of 18:17, 12 March 2024

Division D - Construction Details

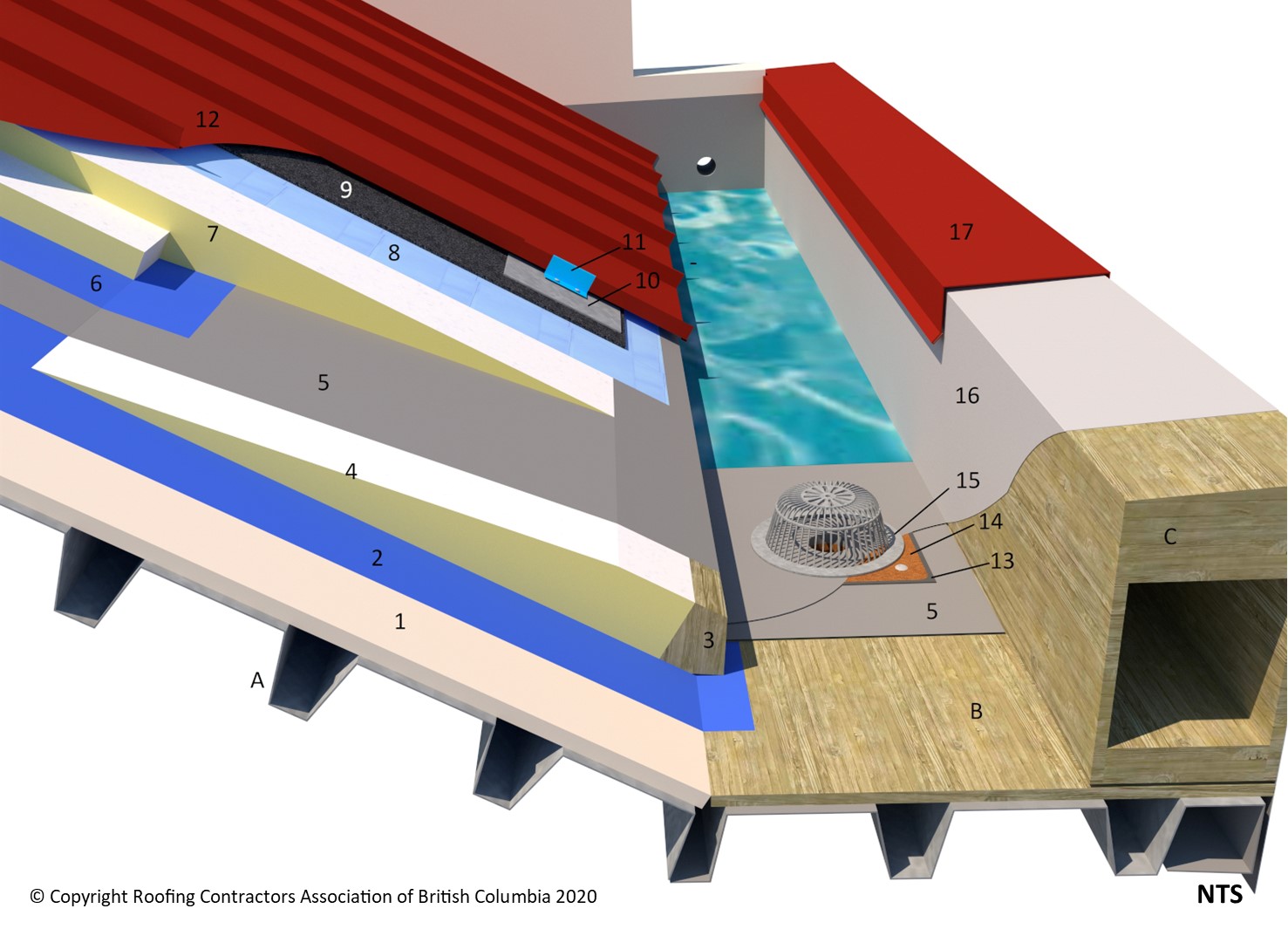

ASM | Membrane Gutter (Insulated Assembly) ( Article 11.1.4.3. and Article 11.3.3.8.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

ASM Details

1 WORK INCLUDED

- (1) Deck overlay

- Required for continuous support of the underlayment when the deck is not suitable.

- (2) Underlayment (lower)

- The type of underlay required is determined by roof slope.

- (3) Wood blocking

- (4) Insulation

- Tapered to support gutter membrane, which is tied into underlayment, to ensure any water intrusion into roof system drains into gutter.

- (5) Gutter Membrane

- (6) Underlayment (upper)

- (7) Upper insulation

- Tapered at lower edge to conform to lower insulation slope. All flat panels must be offset and stagger layers 300 mm (12").

- (8) Vapour-permeable separation membrane

- Installed over insulation and required on all insulated Architectural Sheet Metal Roof Systems. The material must be located between the insulation and metal panels/ventilation material (see 8.1.2 Design)).

- (9) Ventilation beneath panels

- Recommended over asphaltic underlays and / or as required in this Standard (see 8.1.2 Design).

- (10) Bearing plate

- Only thermally non-conductive clips or bars passing through the insulation assembly, or mechanically fastened bearing plates, may be used to secure and support insulation panels, or provide support for panel clips.

- (11) Architectural metal panel clip

- (12) Architectural metal roof panel

- Lower, installed prior to the pipe flashing, cut hole large enough to allow for movement. Extend 400 mm (16") upslope beyond the pipe.

- (13) Mastic (2-ply SBS) or Sealant (Single plies)

- Drain flange must be embedded in a membrane-compatible mastic and secured to the gutter structure.

- (14) Drain Body

- Mechanically secured through flange (for all drain types, see Part 11 DRAINS and PENETRATIONS in the relevant membrane standard in this Manual).

- (15) Strainer

- (16) Gutter Membrane

- Refer to the relevant membrane standard for application requirements (SBS, EPDM, TPO or PVC).

- (17) Parapet cap flashing

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Built-in Gutter structure. Sloped to drain.

- (C) Parapet

NOTE: See the Standard for additional requirements.

Back to ASM Roof System Details

© RCABC 2026

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.