ASM Roof Systems Standard

ASM Roof Systems Standard

Contents

- 1 Accept Terms Of Use

- 2 Part 1 - General

- 2.1 Section 1.1. Design

- 2.1.1 1.1.1. General

- 2.1.1.1 1.1.1.1. Scope

- 2.1.1.2 1.1.1.2. Coverage and Limitations

- 2.1.1.3 1.1.1.3. References

- 2.1.1.4 1.1.1.4. Defined Terms

- 2.1.1.5 1.1.1.5. Reserved

- 2.1.1.6 1.1.1.6. Objectives

- 2.1.1.7 1.1.1.7. Responsibility for Design

- 2.1.1.8 1.1.1.8. Pre-Design Requirements

- 2.1.1.9 1.1.1.9. Suitability of Design

- 2.1.2 1.1.2. Guarantee Requirements

- 2.1.3 1.1.3. All Systems

- 2.1.4 1.1.4. Replacement and Alterations

- 2.1.5 1.1.5. Reserved

- 2.1.1 1.1.1. General

- 2.2 Section 1.2. Reserved

- 2.3 Section 1.3. Application

- 2.1 Section 1.1. Design

- 3 Part 2 - Supporting Structures: Decks and Walls

- 4 Part 3 - Securing the Roof Assembly

- 4.1 Section 3.1. Design

- 4.2 Section 3.2. Materials

- 4.3 Section 3.3. Application

- 5 Part 4 - Materials

- 6 Part 5 - Deck and Wall Overlays

- 7 Part 6 - Air and Vapour Controls

- 8 Part 7 - Insulation

- 8.1 Section 7.1. Design

- 8.2 Section 7.2. Materials

- 8.3 Section 7.3. Application

- 9 Part 8 - Eave, Valley, and Field Underlayment

- 10 Part 9 - Roof Field (Panel Systems)

- 10.1 Section 9.1. Design

- 10.2 Section 9.2. Materials

- 10.3 Section 9.3. Application

- 10.3.1 9.3.1. Guarantee Term Requirements

- 10.3.2 9.3.2. All Systems

- 10.3.2.1 9.3.2.1. Preparation of Substrate

- 10.3.2.2 9.3.2.2. Preparation of Roofing Materials

- 10.3.2.3 9.3.2.3. General Requirements for Panel Installation

- 10.3.2.4 9.3.2.4. Panel Securement and Seams

- 10.3.2.5 9.3.2.5. Panels Over Ventilation Materials or Voids

- 10.3.2.6 9.3.2.6. Panel Terminations

- 10.3.2.7 9.3.2.7. Reserved

- 10.3.2.8 9.3.2.8. Curved Panels

- 11 Part 10 - Perimeters and Walls

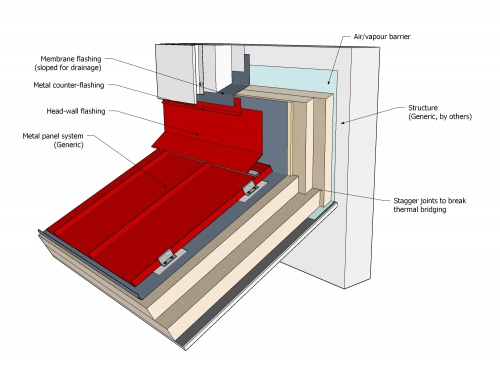

- 11.1 Section 10.1. Design

- 11.2 Section 10.2. Materials

- 11.3 Section 10.3. Application

- 12 Part 11 - Drainage

- 12.1 Section 11.1. Design

- 12.2 Section 11.2. Materials

- 12.3 Section 11.3. Application

- 12.3.1 11.3.1. Guarantee Term Requirements

- 12.3.2 11.3.2. All Systems

- 12.3.3 11.3.3. Drains and Membrane Gutters

- 12.3.3.1 11.3.3.1. Reserved

- 12.3.3.2 11.3.3.2. General Requirements for Cast-iron Roof Drains

- 12.3.3.3 11.3.3.3. Cast-iron Drains Installed with Lead Flashing

- 12.3.3.4 11.3.3.4. Cast-iron Drains Installed with Membrane Flashing

- 12.3.3.5 11.3.3.5. Cast-iron Roof Drain Retrofitting (Replacement Roofing)

- 12.3.3.6 11.3.3.6. Flanged Insert-type Roof Drains

- 12.3.3.7 11.3.3.7. Scuppers and Overflows

- 12.3.3.8 11.3.3.8. Membrane Gutters

- 12.3.3.9 11.3.3.9. External Gutters

- 13 Part 12 - Penetrations and Curbs

- 13.1 Section 12.1. Design

- 13.2 Section 12.2. Materials

- 13.3 Section 12.3. Application

- 13.3.1 12.3.1. Guarantee Term Requirements

- 13.3.2 12.3.2. All Systems

- 13.3.2.1 12.3.2.1. General Requirements for Flashing Penetrations and Vents

- 13.3.2.2 12.3.2.2. Reserved

- 13.3.2.3 12.3.2.3. Separation Between Penetration Flashings

- 13.3.2.4 12.3.2.4. Curbs and Sleepers

- 13.3.2.5 12.3.2.5. Air Vents

- 13.3.2.6 12.3.2.6. Liquid Membrane Flashing

- 13.3.2.7 12.3.2.7. Railings, Ladders, and Other Attached Structures

- 13.3.2.8 12.3.2.8. Reserved

- 14 Part 13 - Linear Metal Flashing

- 14.1 Section 13.1. Design

- 14.1.1 13.1.1. General

- 14.1.2 13.1.2. Guarantee Term Requirements

- 14.1.3 13.1.3. All Systems

- 14.1.3.1 13.1.3.1. Scope and Function

- 14.1.3.2 13.1.3.2. Information Required in Specifications

- 14.1.3.3 13.1.3.3. Securement

- 14.1.3.4 13.1.3.4. Gauge, Dimension Limitations, and Seams

- 14.1.3.5 13.1.3.5. Fit and Finish

- 14.1.3.6 13.1.3.6. Cap and Counter-flashing

- 14.1.3.7 13.1.3.7. Intersections with Other Assemblies

- 14.2 Section 13.2. Materials

- 14.3 Section 13.3. Application

- 14.1 Section 13.1. Design

- 15 Part 14 - The Roof as a Platform

- 16 Notes to Standard

Division B - Standards

Water-shedding Roof Systems: Metals

RGC Standard for Architectural Sheet Metal (ASM) Roofs

This Standard is a consolidation of requirements previously published in the Roofing Practices Manual for Architectural Metal Roofing (Tab 8). It is comprised of fourteen (14) Parts that contain the requirements, guiding principles, recommendations and informative materials necessary for a roof to qualify for a RoofStar 5-Year Guarantee, RoofStar 10-Year Guarantee or RoofStar 15-year Guarantee. Requirements to qualify for a RoofStar 15-Year Guarantee are listed in each relevant Part under Section 1. All RoofStar 15-Year Guarantee requirements must be read together with the General Requirements for each Part in this Standard.

Notes to the Standard are hyperlinked from each Part and can be read by using the link in the Table of Contents for the Standard. Highlighted text within the body of the Standard indicates revisions made within the last twelve (12) months.

This Standard follows a specific structure, incorporates defined terms, and utilizes coloured text to denote specific meaning; this is explained in Division A, Part 2, "Structure and Organization of RPM and Standards". When the requirements in this Standard conflict with other resources found either in this Manual or in manufacturer's published instructions, the rules for Authority and Conflict in Division A, Article 2.3.1.2. shall be applied.

Readers are advised to review relevant materials that can be accessed through the hyperlinks embedded in the body of text.

First Edition: June 14, 2018

Previous Edition: January 31, 2025

Current Edition: Adopted June 12, 2025

All changes to this Standard are effective

July 1, 2025

© RCABC 2025

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.

Part 1 - General

Section 1.1. Design

1.1.1. General

1.1.1.1. Scope

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

1.1.1.2. Coverage and Limitations

- Coverage under the RoofStar™ Guarantee shall be as described in Division A, Article 3.2.1.2.

1.1.1.3. References

- In this Standard, all references to

- the "British Columbia Building Code" (the "Building Code", or the "Code"), to municipal or regional building codes or regulations, or to other standards, presume the current edition that is in force,

- materials mean those materials expressly accepted by the Guarantor, unless stated otherwise, and

- measurements are shown in metric units first, followed by Imperial values (typically in parentheses; see Division A, Article 2.1.3.2., "Measurements").

1.1.1.4. Defined Terms

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part and the Standard:

- Design Authority means the individual or firm responsible for the issuance of project specifications and details to which the project will be bid and constructed. When a Contractor designs a project, the Contractor is deemed to be the Design Authority.

- Finished roof system surface means the top surface of any roof system, inclusive of ballast or overburden.

- Grade-level waterproofing system means an insulated or uninsulated system, designed and constructed at grade with a sheet or liquid-applied membrane, to exclude water.

- Guarantor (used interchangeably with RGC) means the RCABC Guarantee Corporation, which offers the RoofStar Guarantee.

- Linear metal flashing means flashings cut and shaped from flat metal stock, to redirect water at roof perimeters and edges, or to control the flow of water in valleys and drainage spillways. Linear metal flashings also protect roof membranes from weathering and damage and provide an aesthetic finish to the roof system.

- Membrane system means the combination of field and flashing membranes which function together to waterproof underlying materials and systems.

- Observer means a firm or person paid by the building Owner (directly, or through the RGC), who is independent (not a member) of the RCABC, and who is accepted by the RGC to provide Quality Assurance reviews during construction and after completion of the project, according to the terms and conditions set out in RCABC policy .

- Waterproofing roof system means an insulated or uninsulated roof system, designed and constructed on roofs using a sheet or liquid-applied membrane, to exclude water. This type of system typically is installed on roof slopes less than 1:4 (3” in 12”).

- Water-shedding roof system means an insulated or uninsulated roof system, designed and constructed to shed water away from a structure, not to waterproof it. This type of system typically is installed on roof slopes greater than 1:4 (3” in 12”) but may be installed on slopes as low as 1:6 (2" in 12").

1.1.1.5. Reserved

1.1.1.6. Objectives

- Every roof system shall conform to the more stringent of this Standard or the Building Code or By-law having jurisdiction.

1.1.1.7. Responsibility for Design

- Each design of a roof system shall be undertaken by a person or persons qualified in the work concerned (See Article 3.1.3.1. with respect to the securement of the roof assembly).

- The Coordinating Registered Professional is responsible for ensuring the design of the vegetated roof assembly complies with all applicable building, energy, and fire codes having jurisdiction.

1.1.1.8. Pre-Design Requirements

- When a project is designed by an architectural or consulting firm (typically, this applies only to "new construction" projects), the Coordinating Registered Professional is responsible to ensure that the roof assembly design is a multi-disciplinary enterprise that aligns with the designs for structural, plumbing, mechanical, electrical, architectural, and building envelope, together with all trades whose work intersects with the Contractor’s scope of work, to minimize out-of-sequence operations that could compromise the integrity of the completed roof assembly.

1.1.1.9. Suitability of Design

- The Design Authority is responsible for determining the appropriate roof assembly design and must consider (without limitation)

- the requirements of the building code having jurisdiction,

- the structural capabilities or limitations of the building,

- fire resistance and the roof class requirements for the building,

- wind loads (See Part 3 of this Standard),

- the effects of nearby structures on the roof assembly,

- the potential effects of reflected heat on the roof assembly,

- roof system aesthetics, and

- maintenance requirements, including the safety of maintenance workers.

1.1.2. Guarantee Requirements

1.1.2.1. RoofStar 5-Year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

- In addition to Sentence (1), all projects shall comply with

- the project specifications and drawings, and

- the manufacturer's published installation requirements.

1.1.2.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, each project must be designed and constructed in compliance with the requirements published in this Standard, including the following standards which are linked to their referenced Parts:

- A minimum slope of 1:6 (2” in 12”) is mandatory (Article 2.1.2.2.).

- Only panels with a hidden clip securement system may be used to qualify for a RoofStar 15-year Guarantee. Flange-fastened panels are not permitted (Article 9.1.2.2.).

- All penetrations must be flashed by using the split panel detail; flexible boot flashings secured with gasketed screws are not permitted (Article 12.1.2.2.).

- All penetration flashings that do not incorporate a settlement cap must be fitted with two storm collars separated by no more than 75 mm (3”), and each storm collar must be sealed with an untooled bead of sealant Article 12.1.2.2.

1.1.2.3. Quality Control

- Notwithstanding any other requirements in this Standard, the Contractor shall

- bid the project to meet the more stringent of this Standard or the project specifications,

- bid the project to include only RGC-accepted systems and materials,

- ensure that the supporting roof assembly conforms to the requirements and limitations of Article 1.1.3.1.,

- notify the Observer at least 24 hours before construction is scheduled to start or resume (72 hours notice is required for projects further away than 100 km),

- ensure that construction conforms to this Standard and exhibits good workmanship,

- ensure that samples, reports, shop drawings, certificates, manufacturer approvals, warranty documentation, and all other submittals are collected and provided to the Guarantor as required in Article 1.3.2.4., and

- abide by all pertinent RCABC policies.

1.1.2.4. Quality Assurance

(See Note A-1.1.2.4. )

- Notwithstanding any other requirements in this Standard, the Observer shall

- verify that the materials used in construction are accepted by the Guarantor and listed in Division C of this Manual,

- review the construction of the roof system (according to the prescribed number of observations, with consideration for the expected duration of construction) for conformance with the more stringent of

- this Standard,

- conditions and limitations in Division A of the RPM, as they apply,

- the manufacturer’s published requirements,

- the project drawings and specifications, or

- the Building Code having jurisdiction.

- review and report whether the Contractor has met RCABC policy requirements noted in this Standard, and

- perform cut tests or other acceptable methods, whenever required, to verify that the materials and methods of construction conform to this Standard (for example, this may be required when the Contractor has completed more than 30 squares of roofing without an observation).

1.1.3. All Systems

1.1.3.1. Permitted Roof Systems

(See Note A-1.1.3.1.)

- This Standard applies to new construction, and to the partial or complete replacement of existing roofs, constructed as

- uninsulated systems in which metal panels are secured directly to the roof deck or an overlay, and

- insulated systems, in which metal panels are installed above insulation and other roof system materials, and secured to the roof deck using thermally non-conductive clips, girts, or bearing plates.

- Architectural metal roofing systems accepted for use in the RoofStar Guarantee Program must be roll-formed hydrokinetic (water-shedding) systems commonly installed over solid roof decks or rigid insulation panels, but may also be intermittently supported when engineered to resist anticipated live loads (metal panels designed for use as structural (spanning member) systems are accepted for a RoofStar Guarantee only as an architectural metal panel system).

1.1.3.2. Accessibility for Maintenance

- All roofs with a field elevation greater than 7620 mm (25’) above grade should incorporate access to the roof by stairs and a doorway, or with a properly located roof hatch.

- Each roof should be designed to provide safe access for maintenance of roof drains, corners, or mechanical equipment, in a manner consistent with worker safety regulations, should a fall be possible (this principle also applies to roof areas intended for regular occupancy); design elements to mitigate fall hazards should align with the Code having jurisdiction, and with the Workers Compensation Act Regulations.

1.1.3.3. Snow Loads

- In this Standard, a high snow load area is considered a regional area with a Specified Snow Load higher than 3.5 kPa (See Note A-1.1.3.2.).

- Roofs subject to high snow loads must be designed with a supporting deck structure thick enough to support the anticipated live loads, within the acceptable deflection limits defined by the "British Columbia Building Code".

- In locations where moderate to heavy snow cover or high snow load conditions are possible or expected, the Design Authority should give consideration to

- slope,

- entrances and exits,

- penetrations,

- valley construction,

- proper intake and exit ventilation, irrespective of snow cover and drifting, and

- penetrations and their functionality.

- Where snow fences or guards are required by the Design Authority, they should be utilized only where a hazard to the public or property exists; in all other instances it is preferable to allow snow to freely discharge from the roof, to avoid panel distortion and damage to the roof system .

1.1.3.4. Ventilation

- Roofs that do not provide adequate ventilation do not qualify for a RoofStar Guarantee.

- The design and selection of the ventilation system is the responsibility of the Design Authority, and may be achieved by incorporating into the roof design both intake and exhaust vents, including (without limitation),

- eave vents,

- gable end vents,

- hip vents,

- static vents,

- ridge vents, or

- cupolas

- Attic (roof cavity) ventilation must meet the minimum requirements set out by the Code having jurisdiction, even in conditions where snow cover is present (See the "British Columbia Building Code", Division B, Article 9.19.1.3., "Clearances").

- Ventilation must be suitable for

- the slope of the roof,

- the vented area, and

- the design and configuration of the roof structure.

- Ventilation must be provided for

- roofs over cathedral ceilings, and

- compact insulated roof assemblies.

- Continuous ridge venting systems

- are acceptable and are recommended for all areas with vaulted ceilings, and

- may be installed on slopes 1:3 (4” in 12”) and greater, but application on slopes less than 1:3 must be permitted by manufacturer’s published installation instructions.

1.1.3.5. Hot Works

(See Note A-1.1.3.5.)

- The Design Authority may specify that the Contractor must maintain compliance with the RCABC Hot Works Program and consequently manage the Hot Works conducted on site (See Article 1.3.2.1.).

- When the project involves Hot Work, the Design Authority must either

- pre-approve alternate applications already written in this Standard or another applicable Standard published in this Manual, when the specified application is deemed to be fire sensitive by the Contractor as part of the risk assessment process, or

- provide alternate material and application requirements in the Specification for fire sensitive locations on the project.

1.1.3.6. Variances

- When a design is unable to conform to the Standard, the Design Authority may apply to the RGC for a written Variance.

- Application for a written Variance must be made in writing (email correspondence is common), and must

- identify the project name and its civic address,

- identify the RoofStar Guarantee number (if assigned),

- identify the Contractor (if awarded),

- articulate the nature of the design problem,

- identify the RoofStar Guarantee requirement to be varied, and state the desired modification (i.e., reduce the requirement for 203.2 mm (8") to 152.4 mm (6")),

- cite the reference to which the Variance will apply (i.e., Standard name, article number, sentence number, etc.), and

- provide design drawings, photographs, and roof plans, referencing grid lines that identify or articulate the boundaries to which the Variance will be applied.

- Variances are issued by the RGC only to the Design Authority and will be distributed to the Contractor.

- A Variance may be unrestricted in its scope, or it may include one or more conditions, or a restriction in coverage, that will affect the design and construction of the project, to accommodate the varied standard, but this is at the discretion of the Guarantor.

- Variances are issued only for the project-specific issue identified in the written request, and do not constitute general permission to depart from the published requirements in this Standard, for any aspect of the same project or for future projects, designed or constructed by any other firm.

1.1.4. Replacement and Alterations

(The requirements in Subsection 1.1.3., "All Systems", shall be read together with the following Articles)

(See Note A-1.1.4.)

1.1.4.1. General Requirements

- Unless expressly permitted otherwise in this Standard, the design for replacement roofing shall conform to the requirements for new roofing in this Standard.

- New metal panels and flashing, together with existing rainwater gutters, must be protected from incidental damage including, without limitation, damage caused by ladders.

- Existing self-adhered eave protection membrane may be left in place but must be covered with a new layer of RoofStar-accepted membrane, in keeping with the requirements in this Standard.

1.1.4.2. Complete Roof System Replacement

- Complete roof system replacement shall conform to the general requirements in Article 1.1.4.1., unless expressly varied elsewhere in this Standard.

- Roof system replacement means the complete removal and replacement of all roof system and metal flashing materials, exclusive of the air or vapour control layers, and only new replacement materials shall be installed.

- Subject to the requirements in Part 6, "Air and Vapour Controls", the decision to reuse and repair an existing air or vapour control layer remains the responsibility of the Design Authority.

- Roof system replacement projects are eligible to qualify for a RoofStar 5-year Guarantee, RoofStar 10-year Guarantee, or a RoofStar 15-year Guarantee, subject to their respective requirements.

1.1.4.3. Reserved

1.1.4.4. Reserved

1.1.4.5. Tie-ins, Additions, and Alterations to Existing Roofing

- Where a new roof adjoins and ties into an existing roof, the two areas must be isolated and separated by a control joint securely attached to the structure; the curb must be

- at least 127 mm (5”) in height, and

- sealed and flashed in keeping with the requirements for curbs ( Article 12.3.2.4.).

- If project conditions do not allow for a curb joint, the Design Authority must submit an alternative design and obtain a written Variance from the Guarantor that permits the elimination of curb joints (See Article 1.1.3.6.); any alternative design must

- include design specifications and construction details showing a positive water cut-off that fully isolates the existing roof from the new roof, and

- show how the new roof system will be easily distinguishable from the existing roof system.

- Repairs or renovations to an existing roof system that is not covered by a RoofStar Guarantee do not qualify for a RoofStar Guarantee (the term "renovation" means the removal and replacement of, or the application of a cover to, a portion of the roof system).

- Modifications or additions to a guaranteed roof are permissible, subject to various conditions, but must be made by a Contractor qualified to perform work under the RoofStar Guarantee Program.

1.1.5. Reserved

Section 1.2. Reserved

Section 1.3. Application

1.3.1. Reserved

1.3.2. All Systems

1.3.2.1. Hot Works: Contractor Requirements

- The Contractor must maintain the requirements of the RCABC Hot Works Program, including (without limitation)

- Insurance Coverage, wherein the limits carried on the Contractor’s policy must equal or exceed the minimum requirements set by RCABC, and coverage must be unhindered by warranties that limit or exclude coverage when Hot Works is required,

- Education and training, since workers who perform Hot Works must be trained by the Contractor and kept current with acceptable methods,

- the "British Columbia Fire Code", wherein a Fire Safety Plan, preventative methods or alternative work procedures, fire watches, and the use and placement of equipment at the project site must comply with the BC Fire Code requirements for Hot Work,

- a Fire Safety Plan, whereby

- the Contractor must assess the hazards to property and persons and produce a written Fire Safety Plan prior to the start of work, and

- the Fire Safety Plan must be kept on the project site and must be kept current until the project is completed,

- RoofStar Guarantee Standards, to which the Contractor must conform, at each juncture where the interface of different membranes applications constitutes part of the Fire Safety Plan,

- a Fire Watch, in which the Contractor must, as part of the Fire Safety Plan, conduct a fire watch

- that complies with the "British Columbia Fire Code",

- is assigned to competent, trained personnel using suitable equipment, including the use of a hand-held infrared thermometer, and

- is documented in a written fire watch log, and

- Hot Works Notification, wherein the Contractor shall notify the project authority or the AHJ, as and when required, that Hot Works will be performed.

1.3.2.2. Workmanship

(See Note A-1.3.3.2.)

- The Contractor must take reasonable measures to protect the project from damage by the weather, during and at the completion of the project.

- Open penetrations and flashings must be temporarily sealed off from the weather, even when other trades are responsible to make a permanent seal or install overlapping materials (See Article 4.2.1.1..).

1.3.2.3. Contractor Qualifications

- Supervision, manufacturing, and installation of a RoofStar-guaranteed Architectural Sheet Metal Roof System shall be undertaken only by established employees of Contractors, each having obtained a valid

- Architectural Sheet Metal Journeyperson Certificate of Qualification, or

- Sheet Metal trade ticket, together with at least five (5) years of documented experience installing and supervising the installation of ASM roofing (ref. RCABC Policy A-248).

1.3.2.4. Contractor Submittals

(See also Article 9.1.3.1. )

- The Guarantor must receive from the Contractor sealed engineered shop drawings conforming to the requirements in Article 3.1.3.3. and Article 3.1.3.4.

- When tall clips are used as an alternative to EPDM pads (Ref. Article 8.1.3.5.), the Contractor must provide the Guarantor with stamped, written assurance from the Design Authority that

- the clips will adequately secure and support the elevated panels, and

- the panels are suitable as spanning members, and will support anticipated live loads, including loads during construction.

- The Contractor is responsible for providing to the Guarantor a copy of the mill certificate for the sheet metal used to form metal panels and related flashings (the certificate may be provided directly, or shown to the observer who shall take a photographic record of the certificate for the Guarantor (See Article 9.2.1.2. ).

1.3.3. Replacement and Alterations

(The requirements in Subsection 1.3.2., "All Systems", shall be read together with the following Articles)

1.3.3.1. General Requirements

- Unless expressly permitted otherwise in this Standard, all replacement roofing shall conform to the requirements for new roofing in this Standard.

- New metal panels and flashing, together with existing rainwater gutters, must be protected from incidental damage including, without limitation, damage caused by ladders.

- Existing self-adhered eave protection membrane may be left in place but must be covered with a new layer of RoofStar-accepted membrane, in keeping with the requirements in this Standard.

1.3.3.2. Complete Roof System Replacement

- See the requirements throughout this Standard, which apply to both new construction and replacement of a roof system.

1.3.3.3. Partial Roof Replacement

- See the requirements throughout this Standard, which apply to both new construction and replacement of a roof system.

1.3.3.4. Reserved

1.3.3.5. Tie-ins and Additions to Existing Roofing

- Where a new roof adjoins and ties into an existing roof, the two areas must be isolated and separated by a curb joint securely attached to the structure; the curb must be

- at least 127 mm (5”) in height, and

- sealed and flashed in keeping with the requirements for curbs ( Article 12.3.2.4.).

- If the Design Authority has obtained from the Guarantor a written Variance that permits the elimination of curb joints, the new roof system must be fully isolated from the existing roof system with a positive water cut-off that renders the new roof system easily distinguishable from the existing roof system.

1.3.3.6. Repairs and Modifications

- When a roof system that is covered by an active (unexpired) RoofStar Guarantee has been damaged or otherwise requires repairs, work shall conform to the specifications of the material manufacturers, and to the requirements in this Standard, with respect to (without limitation)

- the securement of new materials ( Part 3),

- deck or wall overlays ( Part 5),

- continuity of air and vapour controls ( Part 6),

- thermal resistance ( Part 7,

- eaves, valleys, and underlayment ( Part 8),

- metal panels ( Part 9),

- perimeter details ( Part 10),

- drains ( Part 11),

- penetrations and curbs ( Part 12), and

- linear metal flashings ( Part 13).

- Modifications to an existing roof system covered by an active (unexpired) RoofStar Guarantee, including (without limitation) the addition of new curbs, drains, or penetrations, shall conform to all the requirements in this Standard, or as otherwise stated.

1.3.4. Reserved

Part 2 - Supporting Structures: Decks and Walls

(See Note A-2)

Section 2.1. Design

2.1.1. General

2.1.1.1. Scope

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

2.1.1.2. Defined Terms

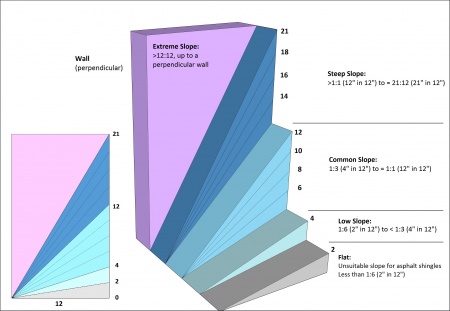

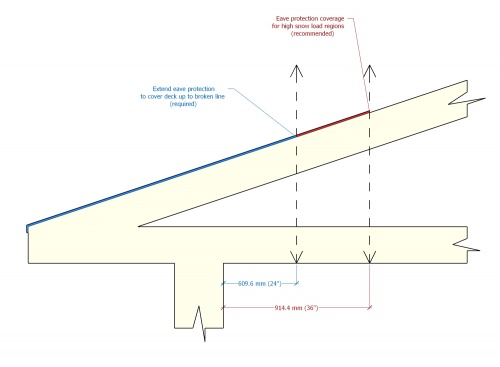

( See Figure 2.1.1.2.-A )

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part:

- Common Slope means a roof with a slope 1:3 (4” in 12”, or 18 degrees), up to and including 1:1 (12” in 12”, or 45 degrees).

- Deck overlay means a panel material secured to the supporting deck, to render the deck surface suitable for the installation of roofing materials.

- Extreme Slope means a roof with a slope greater than 21:12 (21” in 12”, or 84 degrees).

- Flat (roof) means a roof with a slope less than 1:6 (2” in 12”, or 9 degrees).

- Low Slope means a roof with a slope 1:6 (2" in 12", or 9 degrees, up to but less than 1:3 (4” in 12”, or 18 degrees).

- Sheathing means a rigid panel material secured directly onto framing.

- Steep Slope means a roof with a slope greater than 1:1 (12” in 12”, or 45 degrees) up to and including 21:12 (21” in 12”, or 84 degrees).

- Supporting deck ("deck") means the "structural surface to which a roof system is applied" (adapted from ASTM D1079-18 Standard Terminology Relating to Roofing and Waterproofing).

- Wall means a structural or non-structural element in a building that vertically separates space. Walls may separate the outside environment from the interior conditioned space of a building, or they may separate one or more interior spaces from each other (adapted from ASTM E631-15, "Standard Terminology of Building Constructions").

- Wall overlay means a panel material secured to the surface of a wall, to render it suitable for the installation of roofing or wall cladding materials.

2.1.2. Guarantee Term Requirements

2.1.2.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

2.1.2.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, and shall

- be designed with a minimum slope of 1:6 (2” in 12”), which may not be reduced through a written Variance (Note: curved or barrel-shaped roofs may be permitted under a written Variance, subject to a review by the Guarantor).

2.1.3. All Systems

2.1.3.1. General Requirements for Roof Slope

- The Design Authority must design the slope of a roof to achieve proper drainage and must take into consideration the anticipated deflection and settlement of the structure, which may interfere with drainage.

- Roofs with designed slopes less than the stated minimums in Article 2.1.3.2. and in Article 2.1.3.3. (i.e., curved applications; see also Article 9.1.3.4.) will be considered for a RoofStar Guarantee provided

- the design and installation details are submitted in writing to the Guarantor prior to the tendering of documents, and

- a written Variance is issued by the Guarantor prior to close of tender.

2.1.3.2. Roof Slope for New Construction

- Roofs with a designed slope

- equal to or greater than 1:6 (2" in 12") do not require a written Variance from the Guarantor and must be designed to conform to the requirements in this Standard, howsoever they apply,

- less than 1:6 (2" in 12")

- are permissible only through a written Variance from the Guarantor,

- shall be designed to conform to the requirements in this Standard, and

- shall comply with any and all requirements or conditions stipulated in the Variance.

- When the designed slope is less than 1:4 (3" in 12"), the engineered shop drawing package must be accompanied by manufacturer’s literature confirming that this application is acceptable.

- A minimum slope of 1:6 (2” in 12”) is a requirement for a RoofStar 15-year Guarantee (See Article 2.1.2.2.).

2.1.3.3. Roof Slope for Replacement Roofing

- The requirements in Article 2.1.3.1. and Article 2.1.3.2. apply to replacement roofing.

2.1.3.4. Deck Condition and Suitability for Roofing

- The Code having jurisdiction prevails in all cases except where it is exceeded by the requirements published in this Standard.

- Notwithstanding the requirements in this Standard, the RoofStar Guarantee does not cover the supporting deck material or its attachment to the building structure, which is the responsibility of the Design Authority and the building contractor.

- The supporting deck must be dimensionally stable, resist deflection from dead and live loads, and must be capable of accommodating roof system component movement.

- Walls, parapets, curbs, blocking, and penetrations should be constructed or placed by other trades prior to the commencement of roofing work.

2.1.3.5. Drainage Around Obstructions

- Curbs that span 2438.4 mm (96") or more when measured perpendicular to roof slope, across the direction of drainage, should be designed with a cricket to divert water around the curb.

2.1.4. Reserved

2.1.5. Roof Decks

2.1.5.1. Steel Roof Decks

(See Note A-2.1.5.1.)

- Steel decks must be acceptable to the roof system manufacturer and must conform to either

- ASTM Standard Specification A653 / A653M, "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process": Structural (Physical) Quality, minimum Grade 33, with a design thickness of 22-gauge (0.759 mm) or greater and a minimum zinc coating designation Z275, or

- ASTM Standard Specification A792 / A792M, "Steel Sheet, Aluminum-Zinc Alloy-Coated by the Hot-Dip Process": General Requirements, minimum Grade 33, with a design thickness of 22-gauge (0.759 mm) or greater and a minimum aluminum-zinc alloy coating designation AZ150.

2.1.5.2. Concrete Roof Decks

(See Note A-2.1.5.2.)

- Direct contact between metal roofing and concrete, light concrete, stone and mortar must be avoided.

- The selection of a suitable underlay, insulation, and method of attachment to a concrete deck or wall is the responsibility of the Design Authority.

2.1.5.3. All Wood Roof Decks

(See Note A-2.1.5.3.)

- Wood decks

- must conform to the material requirements of the Code (see "British Columbia Building Code", Division B, Part 9, Article 9.23.16.2.. "Material Standards"),

- shall be free of loose knots or cracks,

- shall have a moisture content acceptable to the manufacturer (for self-adhered or adhered membranes, moisture content shall not exceed 19%; Ref. Canadian Wood Council, "Moisture and Wood"), and

- shall be secured to other supporting structural elements of the building in keeping with the published requirements of the Code having jurisdiction; specifying the structural suitability of fasteners is the responsibility of the Design Authority.

- Differential edge movements or deflection exceeding 1/360 of the span must be prevented

- by constructing the deck with tongue-and-groove plywood, and supporting the non-grooved edges with joists or solid blocking, or

- by supporting butt joints at unsupported edges with solid blocking.

- All wood decks shall be

- at least 15.88 mm (5/8") thick, and

- capable of the required pull-out resistance for expected fasteners (knotholes and cracks in decks shall be considered defects and must be covered with sheet metal, mechanically fastened in place),

- All mass timber or wood board decks must be covered with a properly secured, suitable overlay to

- ensure the integrity of the underlayment as mass timber elements contract and expand, and

- protect membranes from wood sap or deck surface irregularities and protruding fasteners; plywood and non-veneered panel decks are exempted from this requirement.

- Securement of overlaid sheathing shall conform to the requirements for wood decks in this Part.

- All types of wood decks should be roofed promptly after installation.

2.1.5.4. Plywood Roof Decks

- Plywood panels should conform to CSA 0121, “Douglas Fir Plywood”, CSA 0151, “Canadian Softwood Plywood”, or CSA 0153, “Poplar Plywood”, but in any event must conform to the requirements published in the Code having jurisdiction (See Note A-2.1.5.4.(1)).

- All non-ferrous (i.e. copper, zinc) metal panel roof systems must be installed over tongue-and-groove plywood decks conforming to the minimum material properties and thicknesses stated in this Article.

- All plywood decks (notwithstanding the minimum requirements for plywood used to overlay mass timber and wood board decks; see Article 2.1.5.5., Article 2.1.5.6., and Article 2.1.5.7.) shall be constructed to conform to the "British Columbia Building Code" for either Part 3 or Part 9 buildings, and shall be

- at least 15.88 mm (5/8") thick, unless exceeded by the specified securement design (Ref. Part 3, "Securing the Roof Assembly"),

- free of loose knots and cracks, which are considered defects and must be covered with sheet metal, mechanically fastened in place,

- securely fastened to roof framing, and installed so that the surface grain (plywood) runs at right angles to the roof framing,

- properly gapped between panels, and

- fully supported along all panel edges.

2.1.5.5. Mass Timber Roof Decks

- Mass timber decks, which include cross-laminated timbers (CLT), nail-laminated timbers (NLT), dowel-laminated timbers (DLT), and traditional glue-laminated timbers (Glulam), are acceptable to the Guarantor but must be overlaid with plywood conforming to the material requirements in Article 5.2.1.1.

2.1.5.6. Non-veneered Panel Roof Decks

- Oriented Strand Board (OSB) is not acceptable deck material for Architectural Sheet Metal panel roof systems.

2.1.5.7. Wood Board Roof Decks

- Wood board decks

- must be overlaid with plywood in keeping with the general requirements for wood decks in Article 2.1.5.3., and

- must be removed and replaced with new material when they are damaged or excessively cupped (excessive cupping is considered 25.4 mm (1”) or more when measured against the mid-span deflection of the deck).

2.1.6. Reserved

2.1.7. Walls

(See Note A-2.1.7.)

2.1.7.1. General

- Wall surfaces must be clean, dry, and smooth, suitable for the application of roof system materials.

- Wood or steel-stud walls must be sheathed with a material suitable for adhering membranes and securing metal flashings; when sheathing is unsuitable, it must be overlaid with an accepted wall overlay.

- Sheathing is considered a wall surface for the purpose of this Standard.

- Wall surfaces suitable for receiving waterproofing materials must extend beyond the maximum installed height of the waterproofing, but in any event must be installed at least 203.2 mm (8”) above the finished roof system surface (For wall overlays, refer to Article 5.2.1.3.).

2.1.8. Electrical Cables and Boxes

(See Note A-2.1.8. concerning electrical systems, fire and shock hazards, and Rule 12-022 of the Canadian Electrical Code, Part I)

2.1.8.1. New Construction

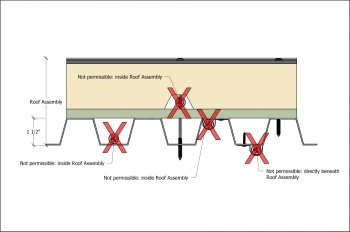

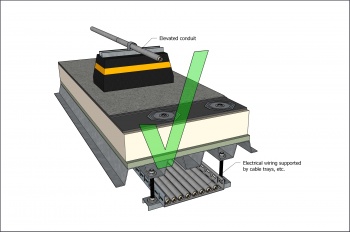

- Electrical cables, raceways or boxes shall not be installed within a roof assembly ( Figure 2.1.8.1.-A ).

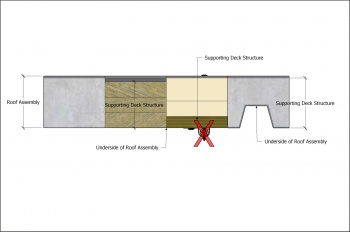

- Electrical cables, raceways or boxes shall not be installed on the underside of a roof assembly, unless

- the supporting deck structure equals or exceeds 76.2 mm (3”) in thickness ( Figure 2.1.8.1.-B ), or

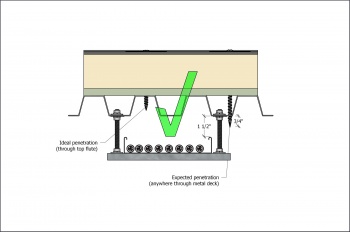

- the cables, raceways or boxes are installed and supported so there is a separation of not less than 38.1 mm (1-1/2") measured between the underside of the roof assembly and the electrical installation ( Figure 2.1.8.1.-C ).

- Notwithstanding either (1) and (2), cables or raceways shall be permitted to pass through a roof assembly for connection to electrical equipment installed on the roof, provided that the passage through the roof is a part of the roof assembly design.

- Electrical cables installed above the roof assembly should be elevated to permit proper support, roof maintenance and future replacement roofing ( Figure 2.1.8.1.-D ).

2.1.8.2. Roof Replacement and Alterations

- If existing electrical cables or boxes do not conform to the requirements in Article 2.1.8.1., the Design Authority must consider the attachment of the roof system above the electrical system, and the requirements set out in Part 3, "Securing the Roof Assembly".

- The Design Authority should

- specify protection of existing electrical cables and boxes (a 4.76 mm (3/16”) steel plate may be used to minimize the possibility of fastener penetration and cutter damage, but protection plates may interfere with mechanical fasteners used to secure the roof system against wind uplift, even for future replacement roofing), and

- provide the building owner with detailed as-built drawings that accurately map the location of electrical cables and boxes.

Section 2.2. Materials

2.2.1. Material Properties

2.2.1.1. Sheathing for Framed Walls

- Framed wall sheathing must be

- moisture resistant fibreglass-faced silicon treated gypsum core board, with a minimum thickness of 12.7 mm (1/2”) (These panels are specifically designed to receive roof membranes and may be installed horizontally or vertically).

- fibre-mat reinforced cement boards with a minimum thickness of 9.53 mm (3/8"), or

- plywood, having a minimum thickness of 12.7 mm (1/2”).

- Where wall sheathing is unsuitable to receive roofing materials, refer to Part 5, "Deck and Wall Overlays".

Section 2.3. Application

2.3.1. Guarantee Term Requirements

2.3.1.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

2.3.1.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, and shall

- be constructed with a minimum slope of 1:6 (2” in 12”).

2.3.2. All Systems

2.3.2.1. Construction of Decks and Walls

- Unless otherwise permitted and described in this Standard, the construction of deck and wall structures, and their suitability for the application of roofing materials, is the responsibility of other trades.

Part 3 - Securing the Roof Assembly

Section 3.1. Design

3.1.1. General

3.1.1.1. Scope

(See Note A-3.1.1.1.)

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

- This Part applies to all new roofs, and to both full and partial replacement roof systems.

- This Part sets out the requirements for

- roofs that support overburden, or fixed amenities and equipment, and

- roofs where only part of the system must be replaced.

3.1.1.2. Intent

(See Note A-3.1.1.2.)

- The requirements in this Part intend to support and conform to or exceed the Building Code.

3.1.1.3. Limit of Liability under RoofStar Guarantee

- Notwithstanding Article 3.1.1.2., the materials presented herein are based on an interpretation of the Code and are not the Code itself; therefore, the reader is responsible to exercise good judgement, and to read, understand and comply with the Code, as and how it applies to the reader’s particular project and its design requirements.

- Where the Code can be shown to exceed the requirements, guiding principles, and recommendations of this Part or any related Part in this Standard, the Code shall prevail.

- Compliance with this Part or the Code does not guarantee that a roof will not succumb to forces exerted by wind, and therefore neither the Guarantor nor the Contractor will accept any responsibility for damage to, or failure of, a roof system caused by wind; too many variables beyond the control of this Standard affect the wind resistance performance of a roof system, including (without limitation)

- the continuity or discontinuity of air and vapour control layers of the entire building enclosure,

- openings in the building (windows and doors, which are often occupant-controlled and not static), and

- wind strength, which may exceed the codified numeric wind speed values used to calculate wind resistance for the roof system (Ref. "British Columbia Building Code 2024", Division B, Appendix C, "Table C-1").

3.1.1.4. Defined Terms

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part:

- Registered Professional has the same meaning as that used in the "British Columbia Building Code 2024", Division C, Article 2.2.1.2., "Structural Design".

- Specified Wind Load means the calculated force of wind exerted on the roof of a specific building, according to the requirements in the "British Columbia Building Code 2024", Division B, Part 4, Section 4.1., "Structural Loads and Procedures".

3.1.2. Guarantee Term Requirements

3.1.2.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

3.1.2.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee.

3.1.3. All Systems

3.1.3.1. Responsibility for Design

- The Design Authority is responsible for determining Specified Wind Loads for each roof system and each roof area of a project, including roofs that support Vegetated Roof Systems or any other overburden, amenities, or equipment.

- Acceptance of a roof for a RoofStar Guarantee is predicated on the assumption that the Design Authority has performed Due Diligence with respect to Specified Wind Loads and has provided the Contractor with sufficient information to construct a roof system that complies with the Code.

3.1.3.2. Calculation of Specified Wind Loads

- A registered professional "skilled in the work concerned" must perform or validate the calculation of Specified Wind Loads (See the "British Columbia Building Code 2024", Division C, Part 2, Article 2.2.1.2., "Structural Design"), using

- the "Wind Uplift Resistance Calculator" (formerly "Wind-RCI"), or

- the formulae and procedures in the "British Columbia Building Code 2024", Division B, Part 4, Subsection 4.1.7.,"Wind Load" (See Note A-3.1.1.1.).

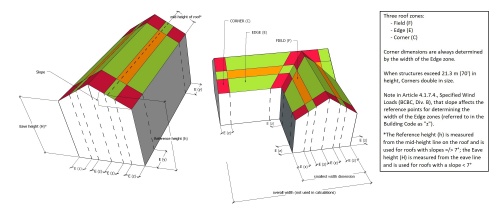

- Each roof area, at each level (elevation), shall be divided into three principal roof zones ( Figure 3.1.3.2.-A ), and the Design Authority shall be responsible for calculating the Specified Wind Loads for each zone (Ref. the "British Columbia Building Code 2024", Division B, Part 4, Article 4.1.7.6., "External Pressure Coefficients for Low Buildings").

- Roof zones are defined in this Standard as follows:

- Field (F) – the interior of the roof bounded by the Edge and the Corners.

- Edge (E) – the perimeter zone (minus the corners), measured as either 10% of the smallest building width ("least horizontal dimension"), or 40% of the building height, whichever is less. Notwithstanding the requirements in the "British Columbia Building Code", the Edge zone shall not be less than 2.0 m (7').

- Corner (C) – part of the perimeter but not less than 2.0 m x 2.0 m (7’ x7’) in size, the Corner area is defined by the Edge in both directions at the corners. Where the roof geometry includes an inside corner, the corner zone dimensions shall be the same as those for an outside corner, applied equidistant in each direction from the inside corner ( Figure 3.1.3.2.-A ).

Figure 3.1.3.2.-A Principal Roof Zones

Forming Part of Sentence 3.1.3.2.(3)

(Click to expand illustration)

- A roof area that is divided into smaller segments by means of control joints (roof dividers, i.e., a fire wall) or expansion joints, shall be considered one roof area for the purpose of calculating the Specified Wind Loads, unless the height of a control joint or expansion joint exceeds 1 m (39"), in which case the Specified Wind Loads for each roof segment shall be calculated separately (See Figure 3.1.3.2.-B ).

- When a building is designed with multiple roof levels (at different elevations), and the roofs are adjacent each other (having a common wall), the Specified Wind Loads for each level, and for each roof area on that level, shall be calculated separately from loads for the adjacent level, unless the elevation difference between adjacent roof levels is less than 1.524 m (5’).

- When the shape of a single-level roof varies in width or length, the smallest width dimensions shall be used in the calculation of Specified Wind Loads (Ref. “minimum effective width” as defined in the "British Columbia Building Code", Division B, Part 4, Article 4.1.7.2., "Classification of Buildings").

Figure 3.1.3.2.-B Roofs Divided by a Wall

Forming Part of Sentence 3.1.3.2.(4)

(Click to expand illustration)

- When a roof area intersects the corner of a wall, the Edge zone on either side of the wall corner must be treated as a roof Corner (2 x C) Figure 3.1.3.2.-B ).

- When an existing roof system is specified for partial replacement, the Design Authority must

- calculate the Specified Wind Loads for the roof,

- determine if securement of the remaining roof components (left in situ) is sufficient to resist the Specified Wind Loads,

- determine a suitable method of securement or have the system of securement engineered, and

- calculate and design securement for any structures or equipment.

- Roof systems should be designed in conjunction with the electrical systems for the building, to avoid unnecessary interference with roof system securement (See also Subsection 2.1.8., "Electrical Cables and Boxes").

- Mansards are a roof system and are therefore subject to the requirements in this Part.

- Securement of an adjoining waterproofing system shall be made in accordance with the requirements in the applicable Standard.

3.1.3.3. Resistance to Specified Wind Loads

- The wind uplift resistance capabilities of the selected roof system must equal or exceed the Specified Wind Loads calculated for each roof zone to which the system will be applied (see Article 3.1.3.2.).

- Engineered designs to resist wind uplift may refer to the "British Columbia Building Code", Div. B, Appendix C, "Table C-2", which lists various types of loads, including wind loads, for specific reference locations throughout the province.

- Each engineered design must include, without limitation, the following:

- Metal panel profile and gauge

- Type of clips

- Bearing plates

- Drag load components

- Fasteners (type, size and spacing)

- Roof assembly components (i.e. underlayment, insulation)

- Deck Substrate

3.1.3.4. Resistance to Other Loads

(See Note A-3.1.3.4.)

- In addition to its capacity to resist Specified Wind Loads, the roof system must be capable of resisting or accommodating

- all anticipated live and dead loads, including (without limitation) other environmental loads, such as rain and snow, expected for the building’s size and location,

- gravity ("drag") loads,

- loads from overburden (See Part 14), and

- thermal expansion and contraction of the roof system components.

3.1.3.5. Reserved

3.1.4. Insulated Roof Systems

3.1.4.1. Securement Against Specified Wind Loads

- New and fully replaced insulated systems shall satisfy the requirements of the "British Columbia Building Code" and this Part, and shall be secured with clips fastened to

- thermally non-conductive, intermediate or continuous supports that pass through the insulation assembly, or

- mechanically fastened bearing plates which are installed on the top surface of the insulation.

3.1.5. Uninsulated Roof Systems

3.1.5.1. Securement Against Specified Wind Loads

- Uninsulated systems shall be designed for securement directly to the roof deck.

3.1.6. Reserved

3.1.7. Roof Replacement and Alterations

3.1.7.1. Complete Roof System Replacement

- Complete roof system replacement projects must be designed to secure the new roof system against displacement by Specified Wind Loads and must follow the design requirements specified by the Design Authority.

Section 3.2. Materials

3.2.1. Reserved

3.2.2. Securement Materials

3.2.2.1. Fasteners

- The Design Authority should specify the correct type of fastener, keeping in mind

- pull-out strength, and

- corrosion resistance (contributing factors to fastener corrosion may include dissimilar metal contact, excessive building humidity, corrosive chemicals within components of the roof system, or corrosive elements provided within the building envelope etc.).

- Fasteners must be capable of securing the roof system components to resist Specified Wind Loads.

- Fasteners

- used to secure metal panels or clips shall conform to the requirements in Article 9.2.1.4., and

- used to secure linear metal flashings shall conform to the requirements in Article 13.2.1.3.

Section 3.3. Application

3.3.1. Guarantee Term Requirements

3.3.1.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

3.3.1.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee,

3.3.2. All Systems

3.3.2.1. Securing Systems with Mechanical Fasteners

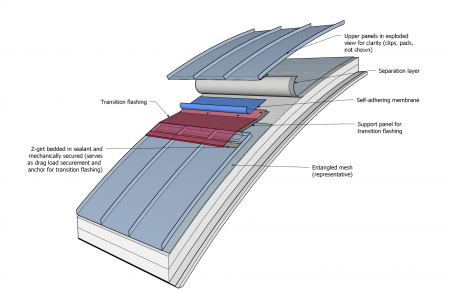

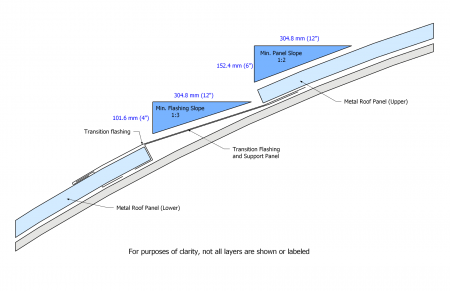

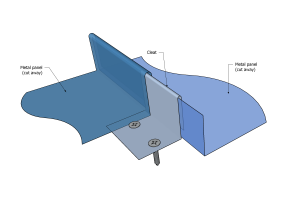

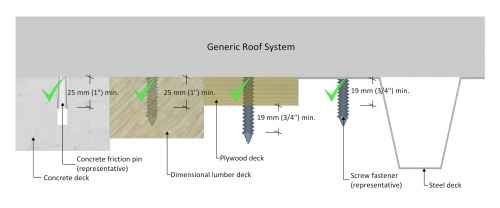

(See Figure 3.3.2.1.-A)

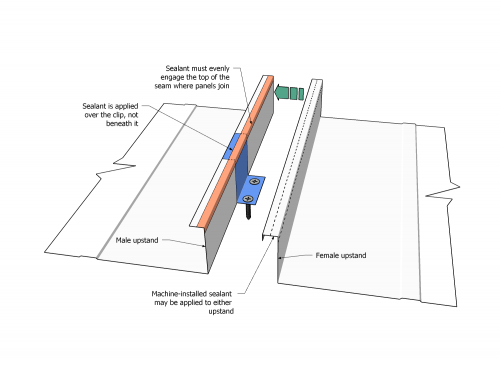

- All metal panels must

- be secured to a firm support, and

- utilize concealed fasteners; exposed fastener securement is not acceptable.

- When clips are used to secure metal panels, the clips must be firmly supported and shall be secured by no fewer than two screw-type fasteners (Ref. Article 9.2.1.4. and Article 9.2.1.5.).

- Concealed fasteners should provide clearance for the underside of the metal panel and must be of a material compatible with the panel or metal clip.

- Regardless of where fasteners are used in the roof system, when they penetrate and secure another material to a substrate, mechanical fasteners must (unless exceeded by the fastener manufacturer’s published requirements)

- penetrate through the bottom surface of

- steel decks at least 19.05 mm (3/4") (fasteners should penetrate the top flutes only), and

- plywood sheathing by at least 19.05 mm (3/4").

- penetrate into solid dimensional lumber or concrete by at least 25.4 mm (1").

- penetrate through the bottom surface of

Figure 3.3.2.1.-A Fastener Penetration Into or Through Deck

Forming Part of Sentence 3.3.2.1.(4).

(Click to expand illustration)

3.3.3. Insulated Roof Systems

3.3.3.1. Securement Against Specified Wind Loads

- Insulated systems shall be secured with clips fastened to

- thermally non-conductive, intermediate or continuous supports that pass through the insulation assembly, or

- mechanically fastened bearing plates which are installed on the top surface of the insulation.

3.3.4. Uninsulated Roof Systems

3.3.4.1. Securement Against Specified Wind Loads

- Uninsulated systems shall be secured with clips fastened to the roof deck, in keeping with the engineered design requirements (Ref. Article 3.1.3.3.) and conforming to the material requirements in Article 9.2.1.4. and Article 9.2.1.5.

3.3.5. Reserved

3.3.6. Roof Replacement and Alterations

3.3.6.1. Complete Roof System Replacement

- Roof systems that are removed and replaced in their entirety (excluding the air or vapour controls, which may be left in place at the discretion of the Design Authority) must be secured following the requirements for new roof systems.

3.3.6.2. Partial Roof Replacement

- When only a portion of an existing roof system is specified for replacement, the new materials must be secured to resist wind Specified Wind Loads, following the design specified by the Design Authority (See also Subsection 1.1.4., "Replacement and Alterations").

Part 4 - Materials

Section 4.1. Design

4.1.1. General

4.1.1.1. Scope

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

4.1.1.2. Defined Terms

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part:

- Primary Material means a material used in a roof or grade-level waterproofing system that protects a building interior from water. Primary materials are often exposed to the weather (protected membranes are an exception), and therefore also protect secondary materials from damage. Membranes, metal panels, asphalt shingles, and cedar shakes and shingles, form the core body of materials classified as primary.

- Secondary Material means one which forms part of a waterproofing system or water-shedding system, and which may affect the wind resistance characteristics of the entire assembly but is not necessarily exposed to the weather.

4.1.2. Reserved

4.1.3. Reserved

Section 4.2. Materials

4.2.1. Material Properties

4.2.1.1. Use of Accepted Materials

(For limitations and exclusions pertaining to materials, see Division A, Article 3.2.1.2.)

- All materials installed by the Contractor, for new construction or alterations, must be

- newly manufactured (except for reusable insulation; see Article 7.1.3.2.), and may not be recycled without the expressed, written consent of the Guarantor,

- accepted by the RoofStar Guarantee Program, and

- manufactured by, or listed as acceptable to, the manufacturer of the primary material.

- All uninstalled materials must be

- validated with a packing slip, retained in their original packaging, or their packaging must be retained on site, and made available to the observer for verification and documentation ,

- protected from weather with wrappers approved or recommended by the manufacturer,

- properly stacked, and

- secured above ground or on the roof surface.

- All installed roofing materials that are susceptible to moisture damage must be made watertight by the end of each workday.

- Metals and fasteners must be compatible with each other, to avoid galvanic corrosion which can occur when dissimilar metals contact each other.

Section 4.3. Application

4.3.1. Guarantee Term Requirements

3.3.1.1. RoofStar 5-year and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

3.3.1.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee.

4.3.2. All Systems

4.3.2.1. Application of New Materials

- All new materials installed as part of the roof system shall conform to the manufacturer's published requirements, unless stated otherwise in this Standard.

Part 5 - Deck and Wall Overlays

(See Note A-5)

Section 5.1. Design

5.1.1. General

5.1.1.1. Scope

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

5.1.1.2. Defined Terms

- Words that appear in italics are defined in the Glossary.

5.1.2. Guarantee Term Requirements

5.1.2.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

5.1.2.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee.

5.1.3. All Systems

5.1.3.1. Required Use of Overlays

(See Note A-5.1.3.1.)

- A deck or wall overlay must be specified

- when a thermal layer is required by the Building Code, or

- when the conditions of the deck or wall are unsuitable for receiving roofing materials.

- Uninsulated systems designed for a steel deck require a deck overlay to support the underlayment.

Section 5.2. Materials

(See Division C, "Accepted Materials")

5.2.1. Material Properties

5.2.1.1. Suitability of Overlays

- Deck and wall overlays must be

- listed in Division C,

- acceptable to the manufacturer,

- suitable for the type of deck, and

- suitable for, and compatible with, any membrane or panel application.

- When plywood is used as a deck overlay, only tongue-and-groove plywood is acceptable and must be

- at least 12.7 mm (1/2”) thick when installed over a mass timber deck, or

- at least 15.88 mm (5/8”) thick, when the roof supports overburden.

5.2.1.2. Thermal Barrier

- When the Code having jurisdiction requires a thermal barrier, any material selected from Division C must be suitable for the purpose.

5.2.1.3. Overlays for Walls

- In addition to overlays listed in Division C, walls may be overlaid with

- plywood, provided the plywood is least 12.7 mm (1/2”) thick and is pressure-treated when applied over concrete or concrete masonry units (CMU), or

- fibre-mat reinforced cement boards with a minimum thickness of 9.53 mm (3/8"), conforming to ASTM C1325 (latest edition), "Standard Specification for Fiber-Mat Reinforced Cementitious Backer Units".

5.2.1.4. Fasteners

- Refer to Article 3.2.2.1.

Section 5.3. Application

(This Section shall be read in conjunction with the requirements for substrate preparation in Part 9 and Part 10)

5.3.1. Guarantee Term Requirements

5.3.1.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

5.3.1.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee.

5.3.2. All Systems

5.3.2.1. Support, Arrangement, and Securement of Deck Overlays

- Deck overlays must be

- fully or intermittently supported along all edges by the deck, and

- installed in a staggered pattern (offset) 304.8 mm (12") from adjacent board rows (a minus offset tolerance of 50.8 mm (2") maximum will be permitted to compensate for variance in the manufacturer's tolerance of differing board widths and lengths).

- Deck overlays shall be affixed to the deck with

- mechanical fasteners conforming to the requirements in Article 3.2.2.1.,

- polyurethane foam adhesives acceptable to the manufacturer and conforming to the requirements in Article 3.2.2.2., or

- a combination of mechanical fasteners and polyurethane foam adhesives.

- When mechanical fasteners are used to secure deck overlays, the minimum number of fasteners (in combination with plates) shall be four (4), for every 1219.2 mm x 2438.4 mm (48" x 96") sheet.

5.3.2.2. Overlays on Steel Decks

- Steel deck panels must be overlaid with a suitable substrate to provide a smooth, uniform surface for roofing.

- RoofStar-accepted deck overlay boards used as a thermal barrier to achieve a specific fire rating must conform to the applicable code and insurance requirements for the roof system.

- When the roof system is uninsulated, the deck must be overlaid with at least one 12.7 mm (1/2”) thick layer of

- moisture resistant gypsum core deck overlay board, or

- plywood.

5.3.2.3. Overlays on Concrete Decks

- While metal panels must be separated from a concrete deck to prevent corrosion, a deck overlay is not mandatory, and separation may be made with an underlayment.

5.3.2.4. Overlays on Wood Decks

- A mechanically fastened overlay board is required for any deck structure that does not meet the deck fastening criteria set out in Article 2.1.5.3..

5.3.2.5. Support, Arrangement, and Securement of Wall Overlays

- Wall overlay panels must be

- mechanically fastened with screw fasteners spaced no more than 304.8 mm (12”) O.C., both vertically and horizontally; fasteners must align with structural supports, and shall be placed

- at the perimeters,

- at the corners, and

- in the field, or

- adhered with a polyurethane adhesive, applied with a continuous z-patterned ribbon spaced no less than 304.8 mm (12”) apart.

- mechanically fastened with screw fasteners spaced no more than 304.8 mm (12”) O.C., both vertically and horizontally; fasteners must align with structural supports, and shall be placed

Part 6 - Air and Vapour Controls

(See Note A-6)

Section 6.1. Design

6.1.1 General

6.1.1.1. Scope

(See Note A-6.1.1.1.)

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

6.1.1.2. Defined Terms

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part:

- Air barrier means a material that is manufactured and tested to prohibit the passage of air through that material.

- Continuity means a sealed, resistive, continuous connection

- between control layers that have the same function, and

- between a control layer and another material or object it joins to (i.e., a roof drain or penetration).

- Control layer means a material used in a roof assembly or wall assembly, that is manufactured and tested to resist or control the movement of air, vapour, or liquid water into or through that assembly.

- Vapour retarder means a material that is manufactured and tested to prohibit or regulate the passage of water vapour through that material.

- Water resistive barrier (WRB) means a material that is manufactured and tested to resist the transmission of liquid water through the material, and is usually used in wall assemblies.

6.1.2. Guarantee Term Requirements

6.1.2.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

6.1.2.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year or RoofStar 10-year Guarantee.

6.1.3. All Systems

6.1.3.1. Responsibility for Design

- The Design Authority is responsible to specify

- air and vapour control materials,

- the placement of continuous air and vapour control layers in relation to a roof system and its components, and

- the selection of suitable materials for that application (See Note A-6.1.3.1.).

- The Design Authority is urged to review and consider the performance characteristics of materials available for such applications.

- Coverage under the RoofStar Guarantee shall be as described in Division A, Article 3.2.1.2..

- Notwithstanding coverage provisions in Division A, neither the RoofStar Guarantee Program nor the Contractor will accept any responsibility for damage to, or failure of, the roof system caused by the use or absence of air or vapour control layers.

6.1.3.2. Continuity of Control Layers

- The Design Authority, and trades constructing walls and roofs, are jointly responsible for making proper connections (continuity) between air and vapour control systems, including the transitions between wall systems and roof systems.

- Where air, vapour, or water control layers intersect a roof drain, overflow drain, scupper drain, or penetration, the intersection must be designed for continuity, and drawings must detail the execution of continuity for the Contractor.

- Overflow drains and scupper drains that penetrate wall assemblies must be designed and drawn to prevent air intrusion from the outside environment (Ref. Article 3.1.5.1.).

6.1.3.3. Use of Air Control Materials

- The Design Authority is responsible for the selection of air control materials (some air control layers are considered vapour permeable, others vapour-impermeable); roof systems intended to qualify for a RoofStar Guarantee should be designed according to the regulatory design and installation requirements for effective, continuous air control systems.

- All materials selected by the Design Authority should conform to the material and performance characteristics required in the "British Columbia Building Code", Division B, Article 5.4.1.2., "Air Barrier System Properties".

6.1.3.4. Use of Vapour Control Materials

- Because continuous vapour control layers may be needed to limit “water vapour transmission and condensation, burn protection, and severe climatic conditions” (National Energy Code of Canada for Buildings 2020, Article 5.2.5.3.(1), "Other Considerations"; see also the "British Columbia Building Code", Division B, Article 5.5.1.1., "Required Resistance to Vapour Diffusion"), they are considered discretionary and must be specified by the Design Authority.

- Where continuous vapour control layers are required and specified by Code, the RoofStar Guarantee Program requires that a suitable vapour control system be selected by the Design Authority and properly installed by the Contractor in conformity with the vapour control layer manufacturer’s published instructions, and with the Design Authority’s specified details.

6.1.3.5. High-humidity Building Interiors

- Careful consideration should be given to the performance characteristics of air and vapour control layers when specifying such a membrane for roof systems constructed over high-humidity building interiors, which may be susceptible to the accumulation of moisture within the roof system unless effective air and vapour controls are installed; these building interiors include (but are not limited to)

- swimming pools,

- commercial laundry facilities,

- large aquariums, and

- paper mills.

6.1.3.6. Reserved

Section 6.2. Materials

6.2.1. Material Properties

6.2.1.1. Compatibility with Other Materials

- The material selected for air and vapour control layers must be compatible with any other materials in the roof or wall assembly to which the control layer may come in contact, including (without limitation) contact with primers and adhesives, substrates, solvents, and cleaners.

6.2.1.2. Permitted Materials for RoofStar Guarantee

(See Note A-6.2.1.2.)

- While responsibility for the selection of suitable air and vapour control layers rests with the Design Authority, a roof designed and built to qualify for a RoofStar Guarantee shall not include

- polyethylene sheet plastic, or

- bitumen-impregnated kraft paper.

6.2.1.3. Puncture Resistance and Thickness

- Air and vapour controls should be installed over a continuous smooth plane, regardless of a material's ability to span voids or spaces in the deck.

- Fully supported air and vapour control layers should possess a minimum published static puncture resistance rating of 150 N (34 lbf) (Ref. CGSB-37.56-M for both test method and standard limits) and be either self-adhering or torch-applied; a high puncture resistance is necessary for the membrane to withstand accidental damage during construction.

- Where no deck overlay board is installed and the air and vapour control layers are partially unsupported (for example, on a steel deck), the control layers must possess a published static puncture resistance of at least 400 N (90 lbf).

- Should the air or vapour control layers be used as a temporary roof during project construction by either the Contractor or by other trades, a minimum 2 mm thick self-adhering bituminous or butyl-based membrane is recommended.

6.2.1.4. Self-adhered and Torch-applied Materials

- Self-adhering or adhesive-applied materials should be considered as alternatives to torch-applied membranes when the substrate to which they will be applied is combustible, or when nearby structures, openings or materials present a fire hazard.

- A suitable separation or overlay material may be used as protection from open flame is acceptable; the application of materials to a combustible surface, using a torch, is strictly prohibited.

6.2.1.5. Vapour Controls for Concrete Decks

- Because curing concrete releases considerable moisture that can compromise the performance of a roof system, a vapour control layer installed on new concrete decks (28 days or older) must be selected to prevent condensation inside the roof system.

- A membrane with a permeability of 0.01 perms (Class I) is recommended for applications on concrete substrates, but the selection of vapour control materials is nevertheless the responsibility of the Design Authority.

Section 6.3. Application

6.3.1. Guarantee Term Requirements

6.3.1.1. RoofStar 5-year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

6.3.1.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year or RoofStar 10-year Guarantee.

6.3.2. All Systems

6.3.2.1. Continuity and Support

- The Contractor must

- ensure that air and vapour control layers in the roof system field, and at perimeters, are installed to provide at least 101.6 mm (4”) of overlap, for continuity of matching layers in adjacent assemblies,

- ensure that air and vapour control layers are sealed to penetrations and drains that pass through or enter the roof assembly, and

- seal all control layers to matching layers in adjacent assemblies (i.e., walls), when a roof is replaced.

- Installation of all air and vapour control materials must be smooth and uniform, without wrinkles or fish-mouths, and must also conform to the manufacturer’s published requirements and the Design Authority’s design details.

- All air and vapour control membrane side and end laps must be fully supported, in the field and at transitions with curbs, parapets, walls, and penetrations.

- When self-adhered membranes are applied directly to a steel supporting deck,

- membranes should be oriented parallel to the direction of deck flutes, and

- membrane laps and changes in plane must be supported by deck flutes, or by flat metal supports secured to the deck to span gaps.

- When metal supports are used to span gaps between steel deck flutes, they must be

- fabricated from pre-finished steel with a thickness no less than 24-gauge, and

- secured to the deck with no fewer than two (2) compatible screw fasteners per flute (See Figure 6.3.2.1.-A and Figure 6.3.2.1.-B ).

- Roof drains, overflow drains, scupper drains, and penetrations must be detailed where they intersect an air, vapour, or water control layer, to provide continuity.

6.3.2.2. Torch-applied Materials

- The application of materials to an unprotected combustible material, using a torch, is strictly prohibited.

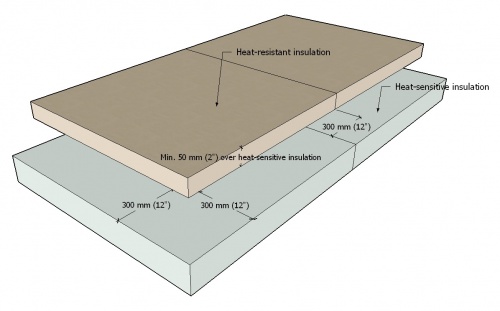

- All combustible materials MUST be protected from open flame by an acceptable separation or overlay material; this includes, without limitation, combustible materials