Difference between revisions of "ASM Eave and Rake Edges (Mechanical Seams)"

Difference between revisions of "ASM Eave and Rake Edges (Mechanical Seams)"

| Line 6: | Line 6: | ||

<big><big>Division D - Construction Details</big></big> | <big><big>Division D - Construction Details</big></big> | ||

<hr> | <hr> | ||

| − | <big><big><big><big><big>ASM 10. | + | <big><big><big><big><big>ASM | Eave and Rake Edges (Mechanical Seams) ([[ASM_Roof_Systems_Standard#10.3.2.3. General Application Requirements for Perimeters and Walls | Article 10.3.2.3.]] and [[ASM_Roof_Systems_Standard#10.3.4.2. Eaves and Rake Edges | Article 10.3.4.2.]])</big></big></big></big></big> |

| − | { | + | {{Template:Construction Details Header}} |

| − | |||

| − | |||

| − | |||

| − | |||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

Revision as of 16:01, 28 June 2022

Division D - Construction Details

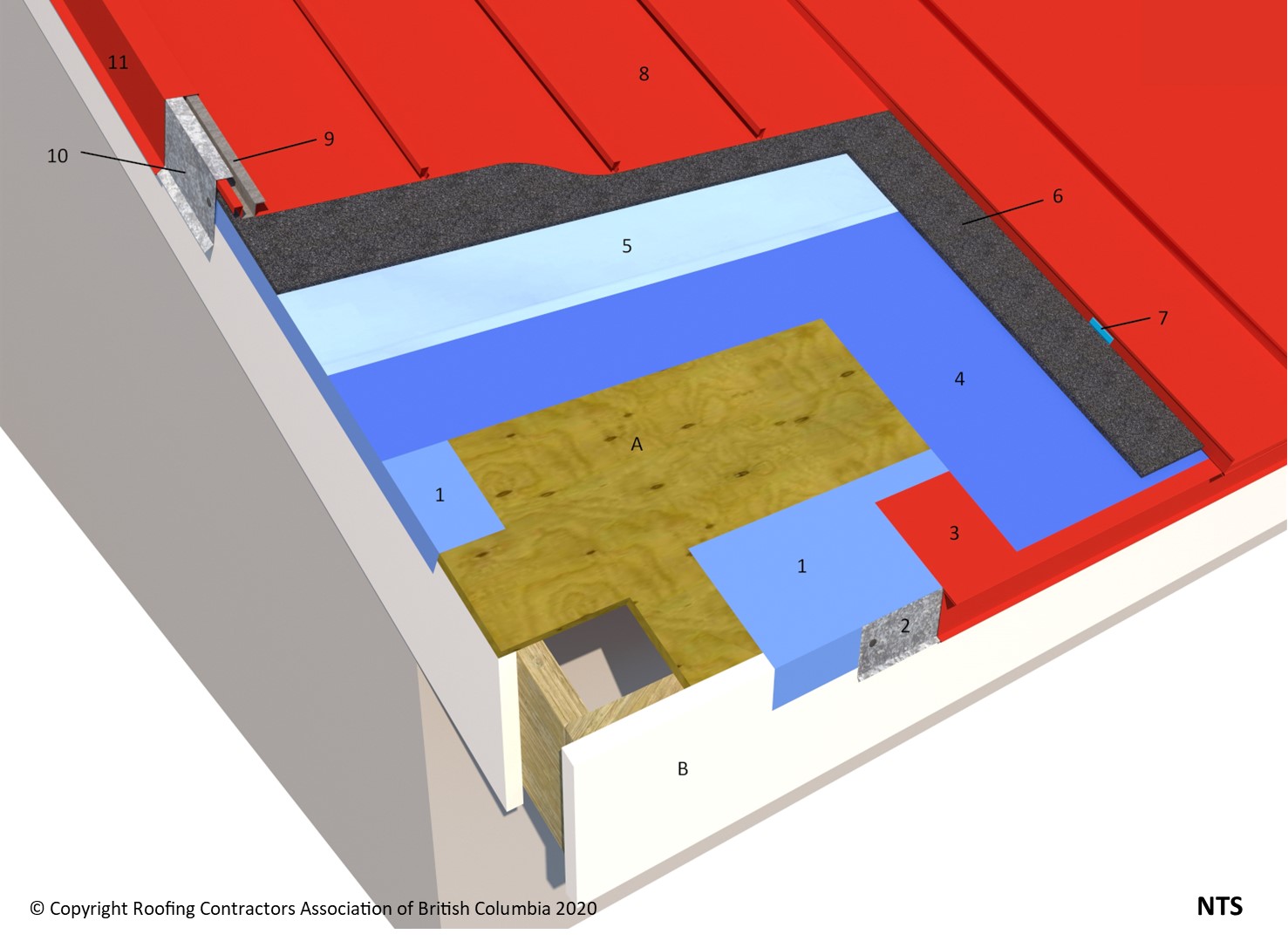

ASM | Eave and Rake Edges (Mechanical Seams) ( Article 10.3.2.3. and Article 10.3.4.2.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

SBS Details

1 WORK INCLUDED

- (1) Separation membrane

- Separates the deck and the metal edge flashing.

- (2) Hook securement strip

- (3) Continuous eave metal flashing

- (4) Eave protection

- One ply of self-adhered modified bituminous underlayment material. Lap 50 mm (2") minimum on sides and 100 mm (4") minimum on ends.

- (5) Underlayment

- Applicable for all Architectural Sheet Metal systems. For slopes less than 1:3, the entire roof slope must be covered with a self-adhered underlayment.

- (6) Ventilation material

- A ventilation space is required on slopes less than 1:3; entangled mesh (shown) may be used as void fill. The ventilation space facilitates drying as condensation forms on the underside of the metal panels.

- (7) Metal panel clip

- Installed in keeping with the metal roof panel manufacturer's printed instructions. Install on EPDM pad (not shown) or use a tall clip sized to support the panel on top of the ventilation layer.

- (8) Architectural metal roof panel

- (9) Girt

- Used to secure standing profile rake edge flashing. Secure girt to deck, through metal panel, and embed girt in two parallel beads of untooled sealant or rows of butyl.

- (10) Outside Securement clip

- Secures standing profile rake edge flashing. Hook clip over standing seam and mechanically fasten clip to outside face of roof.

- (11) Standing profile rake edge flashing

2 RELATED WORK BY OTHERS

- (A) Acceptable deck

- (B) Fascia Board

NOTE: See the Standard for additional requirements.

Back to ASM Roof System Details

© RCABC 2024

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.