Template:Part 10 (Waterproofing Roofs - SBS)

Template:Part 10 (Waterproofing Roofs - SBS)

1 General

1.1 Definitions

Refer to the Glossary for further definitions of key terms used in this Manual.

- Low Door

- means a door with a rough opening less than 200 mm (8”) above the finished roof surface, but no less than 100 mm (4”) above the roof membrane.

- Standard Door

- means a door located at least 200 mm (8”) above the finished roof surface.

- Tall Parapet

- means a parapet taller than 600 mm (24”).

1.2 Design

1.2.1 RoofStar 15-Year Guarantee

- Refer to 1.3.1 RoofStar 15-Year Guarantee for general requirements, to qualify the Project for a RoofStar 15-year Guarantee.

1.2.2 All Projects

- The Design Authority is responsible to specify continuity so that intersecting systems are positively connected. See 10.3.2 Sequencing.

- When a roof Waterproofing System transitions to a Common Slope, Steep Slope or Extreme Slope, the transition must be flashed with separate base and cap membrane plies.

- Base and cap membrane flashing plies should not be terminated at the same height; rather, the cap should lap over the base, onto the vertical substrate, unless fire-sensitive applications apply (see 10.3.3 Alternative Membrane Flashing Approaches).

- Except where low parapets, metal fascia edge flashings and low door sills or window details are incorporated in the design (see also 10.3.7 Door Openings), all membrane flashing (stripping) must extend vertically on perimeter surfaces at least 200 mm (8") above the roof field membrane, to permit a proper watertight seal. Where pavers, ballast, growing media or any other type of Roof Coverings are designed for placement on top of the field membrane, membrane flashing must be carried vertically past the top surface of the covering (the Finished Waterproofing System) at least 200 mm (8”).

- Self-adhering or adhesive-applied materials should be considered as alternatives to torch-applied membranes when the substrate to which they will be applied is combustible, or when nearby structures, openings or materials present a fire hazard. In the alternative, a suitable separation or overlay material as protection from open flame is suitable. The application of materials to a combustible surface, using a torch, is strictly prohibited.

- Only base membranes conforming to the Material requirements outlined below may be installed on the top of a parapet wall.

- Regardless of parapet height, base membrane flashing must be carried up the inside face of a parapet wall no less than 200 mm (8”) above the Finished Waterproofing System.

- Subject to the specifications of the roof design, parapets 600 mm (24”) or less in height may be fully covered with a base membrane flashing. When this is done, the base membrane flashing must not be left exposed to UV radiation, but must be covered with

- a granule-coated cap membrane flashing (see requirements below).

- metal flashing.

- cladding or other wall finishes.

- When walls or tall parapets are specified as part of the roofing work, the remaining surface area of the wall or parapet above the termination of the base membrane flashing must be covered with a water-resistive membrane that has properties consistent with the design and characteristics of the wall assembly. This may be the same membrane used for base flashing, or it may be a self-adhering membrane having a minimum thickness of 1 mm (.040”), provided it

- is applied with the methodology prescribed by the manufacturer.

- positively overlaps the base or cap flashing membrane by at least 75 mm (3”).

- covers the remainder of the wall or tall parapet.

- is protected from UV radiation with a metal flashing, cladding or another wall covering.

- does not extend to cover the top surface of a parapet.

- Tall parapets should be designed with consideration given to ventilation.

- When metal flashing or cladding is installed over a self-adhering base membrane, the membrane must have a high softening point and a minimum flow temperature of 87.7°C (190°F) ASTM D5147 high temperature stability.

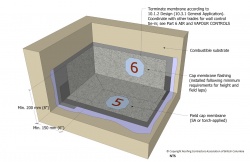

- Cap membrane flashing must be carried up the vertical surface, above the Finished Waterproofing System, at least 200 mm (8”), but may be carried up the full height of the parapet.

- Parapets are not required at the edge of a Conventionally Insulated System that does not support Overburdens, but when they are specified and constructed they must be no less than 125 mm (5") in height, measured from the finished roof surface to the inside top edge of the parapet, in order to facilitate proper metal cap flashing securement. See also 13.3.4 Cap, Counter and Base Flashings.

- When a roof is designed to support Overburden or is held in place with ballast, the design must incorporate parapets with a minimum height of 200 mm (8”) when measured from the top surface of the Overburden or ballast. In any event, the height of the parapet must be designed to retain the Overburden or ballast. See also Part 3 SECURING the ROOF ASSEMBLY.

- Mechanical fasteners used to secure a metal flashing or wall finish must be installed at least 89 mm (3 ½”) above the Finished Waterproofing System.

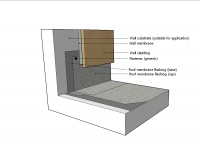

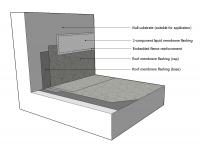

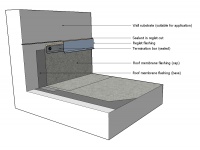

- All membrane flashing terminating on any vertical surface must be secured to the vertical substrate by the Contractor. Exposed membrane edges must also be protected from UV radiation, and from water intrusion. This must be accomplished using one of the following options, ranked according to the maintenance they require (low to high):

- Adhere the roof membrane to the wall surface, and

- protect the exposed membrane edge with overlapping wall membranes and exterior sheathing (Figure 10.1a).

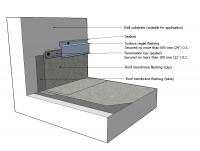

- cover the exposed membrane edge with a secondary, fleece-reinforced 2-component liquid membrane flashing (see 10.3.8 for application requirements) (Figure 10.1b).

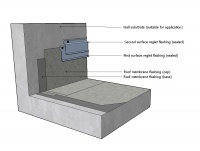

- Mechanically secure the membrane to the wall with a termination bar; caulk the upper edge of the termination bar, and cover the bar with a cut reglet flashing sealed inside the reglet cut with an acceptable sealant (see 13.2.4 Sealants) (Figure 10.1c).

- When the use of a cut reglet is impractical, a surface reglet flashing may be used:

- Mechanically secure the membrane to the wall with a termination bar or metal flashing; caulk the upper edge of the termination bar, and cover the bar with a secondary metal surface reglet flashing that is separately attached to the wall and sealed along the upper edge with an acceptable sealant (see 13.2.4 Sealants) (Figure 10.1d).

- Mechanically secure the membrane to the wall; surface-mount a reglet flashing above the terminated membrane and seal the metal flashing along the upper edge with an acceptable sealant; install a second surface-mounted reglet flashing and seal it along the upper edge with an acceptable sealant (see 13.2.4 Sealants) (Figure 10.1e).

For fastener spacing, see additional Standards in this Part, and 13.3.1 General (Application).Figure 10.3.1 (10.3.1a; 10.3.1b; 10.3.1c; 10.3.1d; 10.3.1e)

- Adhere the roof membrane to the wall surface, and

- When a wall or parapet is faced with multi-wythe masonry or composite panels, and the membrane flashing must be installed over the face of the wall or parapet, the through-wall flashing that separates wythes or courses of panels must be

- supplied and installed by others.

- situated at the next course above the terminated edge of the membrane flashing and any Linear Metal Flashings.

Refer to current seismic codes for suitability.

In the alternative to the above, the entire inside face of a parapet wall must be completely flashed or cladded.

- SBS-modified bitumen membranes are manufactured to transition from horizontal to vertical planes, without the assistance of a cant. Therefore, cant edges are not required.

- Cant edges on existing roofs may be left in place, at the discretion of the Design Authority.

- Diverter flashings must be installed where lower edge of the roof terminates at a wall or at a flat edge where water may freely drain off the roof surface. The diverter is used to prevent the intrusion of water behind wall finishes, or off the roof at an undesirable location.

- When a Waterproofing System transitions

- down a slope onto a lower water-shedding assembly (regardless of slope), the base membrane flashing must be positively lapped onto the water-shedding assembly underlayment by no less than 50 mm (2").

- up a slope and beneath a water-shedding assembly, the base membrane flashing must extend up the slope not less than 300 mm (12"), measured vertically from the horizontal plane.

- with a wall, membrane flashing must positively lap wall membranes and finishes by at least 75 mm (3").

2 Materials

2.1 Membranes

- Membranes used to flash (strip) walls, parapets or other edges shall be reinforced with polyester or a composite scrim, but in any event must conform to the membrane requirements found in 9.2.1 Composition, Thickness and Selection.

- Some membranes may be susceptible to damage from bird droppings, pet urine, chemical contamination (oils, solvents or any discharge from a mechanical unit). The Design Authority is strongly urged to consider these issues in light of the overall Project design, consult with the membrane manufacturer for guidance, and provide adequate membrane protection when it is necessary. See also 14 THE ROOF as a PLATFORM.

- Liquid membranes used as a membrane flashing, or to terminate sheet membrane flashing, must be a fleece-reinforced 2-part liquid flashing system.

- Metal flashings incorporated into roof perimeters and walls must conform to the materials and fabrication standards found in 13.2 Materials.

- When cant edges are specified, they must be fabricated from wood.

2.2 Fasteners

- Fasteners used to secure the upper termination of membranes must be the fasteners specified by the membrane manufacturer or, when a fastener is not specified, a No. 12 screw-type fastener or impact-driven fastener compatible with all secured materials.

2.3 Metal Flashings

- Linear Metal Flashings incorporated into roof perimeters and walls must conform to the materials and fabrication standards found in 13.2 Materials.

3 Application

3.1 General

3.1.1 RoofStar 15-Year Guarantee

- Refer to 1.3.1 RoofStar 15-Year Guarantee for general requirements, to qualify the Project for a RoofStar 15-year Guarantee.

3.1.2 All Projects

- When membrane flashing requires the use of a primer applied to a substrate, all installed membranes must be protected from splashed or dripped primer, as the primer may damage the membranes and cause leaks. This standard also applies to work by other trades, who may use primers for self-adhering membranes typically installed on walls or around doors, windows or other wall penetrations.

- All membrane flashing plies must be

- installed to a substrate that is listed under Accepted Materials, and

- fully bonded to that underlying substrate.

- Membrane flashing plies must be installed according to the manufacturer's published instructions, but in any event must be

- installed from the low point of the roof (for positive laps toward the drain).

- offset the field membrane runs by at least 300 mm (12").

- reinforced at all inside and outside corners with membrane gussets, measuring at least 100 mm x 150 mm (4” x 6”), excluding the tapered ends.

- hand rolled with a membrane manufacturer’s accepted roller.

- Except where low parapets, metal fascia edge flashings and low door sills or window details are incorporated in the design (see also 10.3.7 Door Openings), all membrane flashing (stripping) must extend vertically on perimeter surfaces at least 200 mm (8") above the roof field membrane, to permit a proper watertight seal. Where pavers, ballast, growing media or any other type of Roof Coverings are designed for placement on top of the field membrane, membrane flashing must be carried vertically past the top surface of the covering (the Finished Waterproofing System) at least 200 mm (8”).

- The base and cap membranes must be carried up a vertical face at least 200 mm (8”) but must not be terminated at the same height.

- Base membrane flashing plies must

- extend onto the field by at least 100 mm (4"), or extend at least 100 mm (4") past perimeter mechanical fastener plates installed on the field.

- wrap over the top of the parapet or roof edge and down the outside face by at least 50 mm (2”).

- positively lap any wall membranes or finishes on the outside face of the building.

- be fully bonded at the seams, along all exposed edges.

- be finished and “buttered”, with a torch or hot-air welder, before the end of the working day.

- Cap membrane flashing plies must

- extend onto the field at least 150 mm (6"), or at least 50 mm (2”) past the edge of the base membrane flashing.

- be fully bonded at the seams, along all exposed edges.

- exhibit continuous visible bitumen bleed-out along seam edges, to a maximum of 6 mm (1/4”), accomplished with a torch or hot-air welder.

- All membrane flashing (stripping) must extend vertically on a perimeter surface at least 200 mm (8") above the finished roof surface, to permit a proper watertight seal. Low parapets, metal fascia edge flashings (see also 10.3.7 Door Openings), and low door sill or window details, are exempt from this requirement.

- All membrane flashing terminating on any vertical surface must be secured to the vertical substrate by the contractor. Exposed membrane edges must also be protected from UV radiation, and from water intrusion. This must be accomplished using one of the following options, ranked according to the maintenance they require (low to high):

- Adhere the roof membrane to the wall surface, and

- protect the exposed membrane edge with overlapping wall membranes and exterior sheathing (Figure 10.3.1a).

- cover the exposed membrane edge with a secondary, fleece-reinforced 2-component liquid membrane flashing (see 10.3.8 for application requirements) (Figure 10.3.1b).

- Mechanically secure the membrane to the wall with a termination bar; caulk the upper edge of the termination bar, and cover the bar with a cut reglet flashing sealed inside the reglet cut with an acceptable sealant (see 13.2.4 Sealants) (Figure 10.3.1c).

- When the use of a cut reglet is impractical, a surface reglet flashing may be used on smooth surfaced substrates:

- Mechanically secure the membrane to the wall with a termination bar or metal flashing; caulk the upper edge of the termination bar, and cover the bar with a secondary metal surface reglet flashing that is separately attached to the wall and sealed along the upper edge with an acceptable sealant (see 13.2.4 Sealants) (Figure 10.3.1d).

- Mechanically secure the membrane to the wall; surface-mount a reglet flashing above the terminated membrane and seal the metal flashing along the upper edge with an acceptable sealant; install a second surface-mounted reglet flashing and seal it along the upper edge with an acceptable sealant (see 13.2.4 Sealants) (Figure 10.3.1e).

For fastener spacing, see additional Standards in this Part, and 13.3.1 General (Application). For specific construction requirements, see Construction Detail SBS 10.3.1-4.

- Adhere the roof membrane to the wall surface, and

- When the roof membrane is mechanically secured with a termination bar or a metal flashing, fasteners must be spaced no more than 300 mm (12”) O.C. When a second metal flashing is installed to protect a termination bar or flashing used to secure the membrane, it may be fastened no more than 600 mm (24”) O.C. provided the metal flashing maintains continuous contact with the substrate. See also 13.3.1 General (Application).

- All fasteners used to secure the upper termination of the membrane must be installed no more than 300 mm (12”) O.C. or as required by the manufacturer. When closer spacing is required by the membrane manufacturer, the wall must be constructed or modified to facilitate solid fastener securement.

- When a Waterproofing System transitions with a wall, wall membranes and finishes must positively lap membrane flashing by at least 75 mm (3").

3.2 Sequencing

- Projects must follow proper sequencing. This means that materials must be installed so that they interface with other materials, systems or assemblies, including those installed by other trades, in “shingle fashion” by positively overlapping them below or above. Occasionally, the coordination with other trades requires some adaptation to this standard. When that is the case, any variance to proper detail sequencing must be approved by the Design Authority in writing.

3.3 Alternate Membrane Flashing Approaches

In conjunction with Best Practices for fire prevention, the following Standards apply, and the recommended means and methods should be considered or used as a guideline for designing other risk reduction approaches:

- When field membranes or flashing plies are heat-welded, or if required by construction sequencing, the Contractor must assess the best approach.

- The Project design and installation may incorporate one or more of the following alternatives to conventional membrane flashing methods- 10.3.3.1 Pre-flashing Approach or 10.3.3.2 Picture-frame Approach.

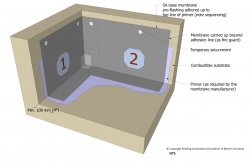

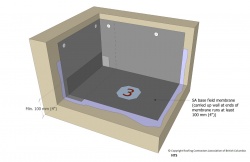

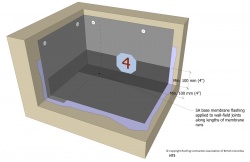

3.3.1 Pre-flashing Approach

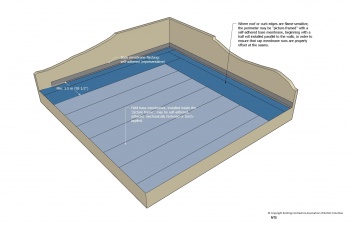

See Figures 10.2a through 10.2d below, to illustrate the concepts described in the following standards:

- Before installing the base field membrane, self-adhering or adhesive-applied base membrane flashing (“pre-flashing”) must be applied to both vertical surfaces and to a suitable substrate on the roof field.

- Base membrane flashings must be finished and “buttered” at the joints using a hot-air welder.

- Base membrane flashing plies must extend

- no less than 100 mm (4”) onto the roof field.

- no less than 200 mm (8”) on walls or tall parapets, or to fully cover parapets up to 600 mm (24”) in height.

- The ends of field membrane runs, applied after base membrane flashing, must continue up the face of the wall or parapet at least 100 mm (4”).

- Additional base membrane flashing must be installed along the lengths of base field membranes, applied to the vertical surface and onto the roof field at least 100 mm (4”).

- Cap field and flashing membranes must be installed in keeping with General Application standards.

- All other applicable Standards in this Manual apply.

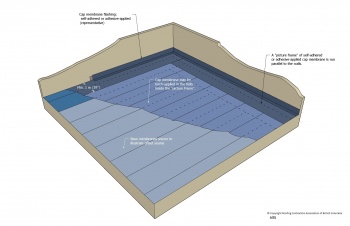

3.3.2 Picture-frame Approach

- Before installing the base field membrane, “picture-frame” the field area adjacent to sensitive locations with self-adhering or adhesive-applied membranes; apply membranes to a suitable substrate on the roof field, to a width of at least 1.5 m (58 ½”), beginning with a half-width sheet along the roof edge. See Figure 10.3.2-1.

- Perimeters must be flashed with self-adhering or adhesive-applied membrane base flashing. Base membrane flashing plies must extend

- no less than 100 mm (4”) onto the roof field.

- no less than 200 mm (8”) on walls or tall parapets, or to fully cover parapets up to 600 mm (24”) in height.

- Field base membrane must be installed and tied into the “picture frame” following the General Application standards for side and end laps (refer to 9.3.1 General).

- Standard application of cap field membranes must be carried no closer than 1 m (39”) of the wall or parapet. See Figure 10.3.2-2.

- Self-adhering or adhesive-applied cap membranes must be applied to complete the field. Side and end laps must be heat-sealed with a hot-air welder.

- Self-adhered or adhesive-applied cap membrane flashing must be applied to parapets or walls, in keeping with General Application standards for membrane flashing. Side and end laps must be heat-sealed with a hot-air welder.

- All other applicable Standards in this Manual apply.

3.4 Membranes

3.4.1 Torch-applied

- The application of an open flame to combustible surfaces is NOT permitted. All combustible surfaces, including (without limitation) decks, walls, blocking or cants MUST be protected from open flame by an acceptable separation or overlay material.

- When the base membrane flashing is torch-applied, all overlay board joints and wall transitions must be sealed with the primary membrane manufacturer’s approved self-adhered membrane or tapes. Alternatively, refer above to 10.3.3 Alternative Membrane Flashing Approaches.

3.4.2 Self-adhered

- Self-adhered membranes must be installed on a clean, uncontaminated surface. Dirty or contaminated surfaces must be covered with

- plywood sheathing with a minimum nominal thickness of 9.5 mm (3/8").

- a wall overlay.

3.4.3 Adhesive and Hot-applied

- Hot-applied membrane flashing must be installed according to the membrane manufacturers’ installation specifications, using conventional Type 3 or 4 oxidized asphalt or Type 3 or 4 SEBS modified asphalt. The asphalt temperature must conform to the membrane manufacturer's minimum application temperature; a minimum application temperature of 205°C (400°F) is required.

- When hot asphalt is used to adhere membrane flashing (stripping), metal base flashings are required on all vertical surfaces, walls, curbs, etc. Refer to 13.3.4 Cap, Counter and Base Flashings.

3.5 Perimeters and Walls

3.5.1 Parapets

- Parapets up to and including a height of 600 mm (24”) must be fully covered with a base membrane flashing.

- Base membrane flashings installed on a parapet must extend onto the outside vertical face of the parapet by at least 50 mm (2").

- Base membrane flashing may not be left exposed to UV radiation any longer than the manufacturer’s recommendations, but must be covered with

- a granule-coated cap membrane flashing (see requirements below).

- metal flashing.

- cladding or other wall finishes.

- When walls or tall parapets are specified as part of the roofing work, base membranes must be terminated at a height above the Finished Waterproofing System no less than 300 mm (12”). The remainder of the wall or parapet surface must be covered with a waterproofing membrane. If specified, use the same membrane employed for base flashing. When an alternate self-adhering membrane is specified, it must be at least 1 mm (.040”) thick and must

- be installed according to the methodology prescribed by the manufacturer.

- positively overlaps the base or cap flashing membrane by at least 50 mm (2”).

- cover the remainder of the wall or tall parapet.

- be protected from UV radiation with a metal flashing, cladding or another wall covering.

- not extend to cover the top surface of a parapet.

- Where a metal coping is specified as the only Linear Metal Flashing, the cap membrane flashing must be carried up at least as high as the inside face of the parapet. Optionally, the cap membrane flashing may be carried across the top of the parapet to the outside edge.

- Where a parapet intersects with a wall, water must be directed to the outer surface of the wall by flashing the union with

- membrane flashing.

- membrane gussets at the corners.

- a metal saddle assembly.

3.5.2 Metal Edge Terminations

Membrane roof Waterproofing Systems may be terminated at the roof edge, flush with the roof surface, using a linear metal edge flashing. Metal edge flashings must be installed to the following standards:

- Conventionally Insulated Systems terminating on the horizontal plane with a metal edge flashing must abut blocking at the roof edge.

- The base field membrane must extend onto the outside face of the roof edge at least 50 mm (2").

- Metal edge flashings must be

- installed over the base field membrane.

- embedded in a membrane-compatible mastic.

- fastened to the roof surface with mechanical fasteners spaced 200 mm (8”) O.C. in offsetting rows.

- joined to each other with lap joints measuring at least 100 mm (4”) and sealed with mastic.

- primed.

- sealed to the base membrane which must extend

- at least 100 mm (4") onto the metal flashing.

- at least 100 mm (4”) onto the field membrane.

- finished with the field cap membrane

- extending to cover the base membrane.

- sealed along the exposed edge with an un-tooled bead of membrane-compatible mastic.

- When a diverter flashing is required, it must be fabricated like a metal edge flashing, and must be secured and sealed to the primary membrane with membrane flashing (stripping). Follow the procedures outlined in 10.3.5.2 (3).

3.5.3 Cant Edges

- Existing and new cant edges must be flashed with membrane plies, installed in keeping with the requirements in 10.3.1 General, and must lap onto the roof field in keeping with the Standards published in this Section, when measured from the base of the cant. See also 13.3.6 Cant Edges.

3.5.4 Transitions with Water-shedding Systems

- Where two roof systems intersect, materials must be compatible with each other, or must be separated from contact by an intermediate separation layer.

- When a Waterproofing System transitions

- down a slope onto a lower Water-shedding System, the waterproofing membrane must lap over the Water-shedding System by no less than 50 mm (2").

- up a slope and beneath a Water-shedding System,

- the field membrane or membrane flashing must extend up the Water-shedding System slope at least

- 200 mm (8”), plus 75 mm (3”) for the overlap by the Water-shedding System, when measured vertically from the water plane, or 150 mm (6”) when measured vertically from the maximum water level.

- 300 mm (12”) plus 75 mm (3”) for the overlap by the Water-shedding System, when measured vertically from the water plane or maximum water level, in regions with typical heavy snow.

- the termination of the membrane on the slope must be mechanically secured, separately from the Water-shedding System.

- fasteners for the Water-shedding System must be at least 200 mm (8”) above the Finished Waterproofing System (when measured vertically from the water plane), or 300 mm (12”) for regions with heavy snow.

- the Water-shedding System materials must overlap the Waterproofing System by at least 150 mm (6”).

- the field membrane or membrane flashing must extend up the Water-shedding System slope at least

- with a wall, wall membranes and finishes must positively lap membrane flashing by at least 75 mm (3").

3.6 Expansion and Control Joints

See 2.4 Expansion Joints and 2.5 Control Joints above. Membrane application must conform to the general requirements outlined in 10.1 General.

- Expansion joints constructed as a raised divider must have a sloped top surface and must extend in height above the Finished Waterproofing System no less than 200 mm (8"). The minimum height of the expansion joint may be reduced to 100 mm (4") if the primary roof membrane flashing is fully supported and sealed over the top.

- Proprietary elastomeric expansion joint systems, manufactured with an EPDM-based core and flanges that can be fully bonded to the primary membrane, are acceptable for use in Waterproofing Systems when the systems are located a minimum of 200mm (8") above the Finished Waterproofing System and are completely sheathed (covered) with sloped Linear Metal Flashing. Such joints must be

- accepted for use in the RoofStar Guarantee Program.

- compatible with the roof membrane and acceptable to the membrane manufacturer.

- designed and manufactured to accommodate building movements of at least 500% elongation at -40°C (-40°F) across its length and at all vulcanized points.

- factory-fabricated by means of vulcanization.

- manufactured as one piece, complete with all joints, details and connections.

- bonded with the primary membrane in a manner acceptable to the manufacturers of both the expansion joint and the membrane to which it will be bonded.

- Field splicing of proprietary elastomeric expansion joints is permitted only when made with a machine acceptable to the expansion joint manufacturer. All other field splices are not permitted.

3.7 Door Openings

- Standard door openings must be flashed with membrane, reinforced with gussets at the sill corners, carried vertically on all surfaces of the door sill opening at least 100 mm (4”).

- The RGC recommends against low door openings because of their propensity to leak. Nevertheless, when a low door opening is specified to comply with building codes, it must be waterproofed in keeping with the following standards:

- The opening at the curb must be waterproofed before the door frame and sill is installed, by one of the following accepted methods:

- Sheet membrane flashing

- reinforced with gussets at the sill corners.

- carried vertically on all surfaces of the door sill opening at least 100 mm (4”).

- terminated on a mechanically attached water-stop flashing sized to fit underneath the door sill and sealed to the opening with membrane flashing.

- A metal water stop flashing, fabricated with folded, welded or soldered corners and mechanically attached to inside of door sill opening. The pan must be sealed to the door curb and opening with membrane flashing.

- Reinforced liquid membrane flashing applied in keeping with the requirements for sheet membrane flashings above.

- Sheet membrane flashing

- The roof must be sloped away from the door opening.

- Overflow drains must be

- installed on the same roof area, and located at least 25 mm (1") below the door sill.

- capable of flow rates equivalent to or greater than those of the primary roof drains for the roof areas adjacent to the door opening (see also 11.3.2.5 Scuppers and Overflows).

- When the building interior transitions to a patio or occupied roof surface through a flush door opening, the walking surface of the patio or roof must protect the roof membrane from damage and provide a drainage space below the walking surface measuring at least 12.7 mm (1/2”). Alternatively, pea gravel installed on a drainage board may be used.

- Overhangs above the door are recommended wherever practical, to minimize water intrusion that occurs from wind-driven rain or from snow accumulation.

- The opening at the curb must be waterproofed before the door frame and sill is installed, by one of the following accepted methods:

3.8 Liquid Membrane Flashing

Where sheet membranes terminate on walls, or where flashing with sheet membranes may not be practical or even possible, only a RoofStar-accepted reinforced 2-component catalyzed polymethyl methacrylate (PMMA) liquid membrane may be used. The following standards pertain to the application of these materials:

- Use only liquid flashing membranes that are compatible with the primary membrane.

- Ensure proper preparation of the substrate, which must be clean, dry and free of contaminants. Preparation must follow the published procedures published by the flashing manufacturer.

- Liquid membranes must be applied with clean, straight, plumb edges. Therefore, mask the boundaries of areas to which liquid membrane will be applied, ensuring adequate coverage on all surfaces.

- For all applications,

- prime the substrate above the sheet membrane flashing, as directed by the manufacturer of the 2-part liquid flashing system.

- apply a base layer of catalyzed liquid membrane resin within the area masked for coverage.

- reinforce the base coating with the manufacturer’s fleece and cut it to size so that the fleece is set in from the masked area no more than 3 mm (1/8”).

- ensure the fleece is fully saturated with liquid, following the published instructions from the manufacturer.

- coat the fleece with a second application of catalyzed liquid membrane resin, covering the masked area.

- When a granule surface or textured finish is specified, the granules or texturing material must be broadcast into a third coat.

- On vertical membrane terminations, apply the liquid membrane to provide no less than 50 mm (2") coverage, both above and below the sheet membrane termination.

- For use as a substitute for sheet membrane flashing, the reinforced liquid membrane flashing system must extend 200 mm (8”) both vertically and onto the field membrane.

Application rates and guidelines issued by the manufacturer of the liquid flashing product must be followed, unless superseded by these Standards.

See also 11.3.3.3 Liquid Membrane Flashing for additional applicable standards.