Difference between revisions of "Materials:(Laing) SS 150"

Difference between revisions of "Materials:(Laing) SS 150"

(→SYSTEM DESCRIPTION) |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

<big><big>Division C - Accepted Materials</big></big> | <big><big>Division C - Accepted Materials</big></big> | ||

<hr> | <hr> | ||

| − | <big><big><big><big><big> | + | <big><big><big><big><big>(Laing) SS 150 Panel</big></big></big></big></big><br> |

<big><big><big>by Laing Roofing Ltd.</big></big></big><br> | <big><big><big>by Laing Roofing Ltd.</big></big></big><br> | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 17: | Line 17: | ||

;'''Contact Address''': See the current Membership list and contact information at [http://www.rcabc.org/members/find-a-member/ www.rcabc.org] | ;'''Contact Address''': See the current Membership list and contact information at [http://www.rcabc.org/members/find-a-member/ www.rcabc.org] | ||

;'''Product Group - Standing Seam Metal Roof System''' | ;'''Product Group - Standing Seam Metal Roof System''' | ||

| − | ;'''Panel Machine''': | + | ;'''Panel Machine''': New Tech Machinery SSQ2 MultiPro Roof and Wall Panel Machine |

;'''Panel Name''': SS150 | ;'''Panel Name''': SS150 | ||

;'''Date of Acceptance''': June 12, 2025 | ;'''Date of Acceptance''': June 12, 2025 | ||

Latest revision as of 16:07, 26 June 2025

Division C - Accepted Materials

(Laing) SS 150 Panel

by Laing Roofing Ltd.

| The metal panel listed and described below is accepted for use in the RoofStar Guarantee Program. |

The roofing assembly / material information published below and in the RCABC Roofing Practices Manual DOES NOT represent a complete set of the manufacturer's published data, nor does it represent a detailed specification. The preparation of a detailed specification is the responsibility of the design authority. For more information about this product or system, consult the manufacturer. |

OVERVIEW

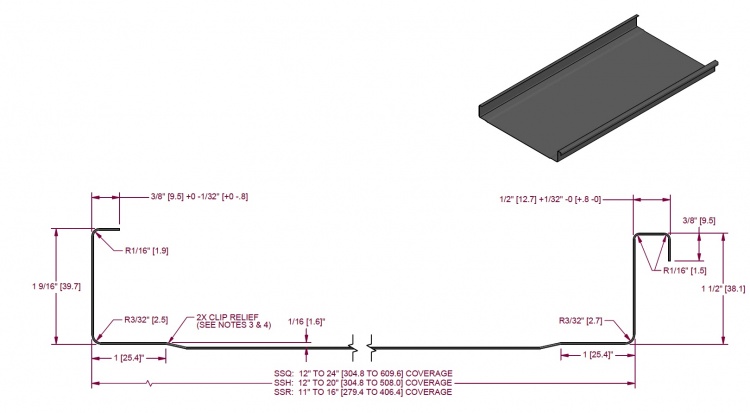

The SS150 standing seam panel is formed with an on-site/in-shop continuous metal roofing panel roll forming machine New Tech Machinery SSQ II. This machine produces a standing seam panel with a seam height of 38.1 mm ( 1 1/2" ) and profiles can vary from 304.8 mm (12") wide up to 609.6 mm (24") wide.

SYSTEM DESCRIPTION

- General: The SS150 panel is a standing seam concealed fastener roofing panel produced from coil stock. The maximum spacing of the clips is 609.6mm ( 24" ) on centre.

- Seam Height: 38.1 mm (1-1/2")

- Panel Widths: 304.8 mm (12") wide up to 609.6 mm (24") wide

- Maximum Length: 46 m (150')

- Range of Application: the panels are used on metal and wood sloped roofs in residential, institutional, industrial and commercial projects, for re-roofing or new construction.

- Panel Attachment:

- Panel Stiffeners: Optional for panel widths up to and including 304.8 mm (12") but required for wider panels (See Article 9.2.1.1., Sentence (5) in the Standard for Architectural Sheet Metal (ASM) Panels).

- Fasteners (Screws):

- Fasteners used to attach panel clips to plywood must be (minimum) No. 10-12 pancake head wood screws. Minimum two fasteners per clip to be used. Length to penetrate plywood min 3/4".

- Fasteners used for drag load securement to resist all anticipated live and dead loads, including other environmental loads expected for the building’s size and location, to be determined by a registered P.Eng on a case by case basis.

- Panel Clips: Two piece assembly consisting of steel base approx 25.4mm ( 1") wide x 144.3mm (4.5") long, minimum thickness of 0.8mm G-90 Galv. and an upper tab, 23.62mm (.93") high, minimum thickness of 0.6 G-90 Galv. One panel clip spaced at 609.6mm ( 24" ) on centre maximum. Minimum two fasteners per clip to be used. Length to penetrate plywood min 3/4". Clip spacing as specified on engineered shop drawings (Ref. Standard for Architectural Sheet Metal (ASM) Roof Systems, Article 3.1.3.3. and Article 3.1.3.5.)

- Deck Requirements: in keeping with the Standard for Architectural Sheet Metal (ASM) Systems.

PROFILE

| SSQ675 Panel |

|---|

|

TECHNICAL DATA SHEET

Click below for the Technical Data Sheet

SITE CONDITIONS

Minimum roof slope is 1:4 (3" in 12"). Severe conditions (heavy snow or ice) minimum slope is 1:1.5 (8" in 12").

PERFORMANCE REQUIREMENTS

- Wind Uplift Resistance: Panel securement shall conform to the requirements in Part 3 of the Standard for Architectural Sheet Metal (ASM) Systems.

- Materials:RoofStar (RGC) accepted metal panel systems shall be formed of steel conforming to the requirements published in Section 9.2. of the Standard.