PART 1 WP

PART 1 WP

1 References

In this Manual, all references to

- the British Columbia Building Code, municipal or regional building codes or regulations (collectively referred to as the “Code”), or other standards, presume the current edition that is in force.

- materials are assumed to be Accepted by the RGC, unless stated otherwise.

2 Definitions

- Assembly

- means a system in combination with its supporting deck structure (adapted from ASTM D6630-08 Standard Guide for Low slope Insulated Roof membrane Assembly Performance).

- Contractor

- means the installer of a project. For the purpose of issuing a RoofStar Guarantee, Contractor shall be read to mean an Active Member of the RCABC.

- Design Authority

- means the individual or firm responsible for the issuance of Project specifications and details to which the Project will be bid and constructed. When a Contractor designs a Project, the Contractor is deemed to be the Design Authority.

- Finished waterproofing/water-shedding system

- means the top surface of a waterproofing system or water-shedding system that may include ballast or that supports overburden.

- Guarantor

- means the RGC RoofStar Guarantee Program that issues the RoofStar Guarantee ("Guarantee"); the two terms may be used interchangeably.

- Linear metal flashings

- are flashings cut and shaped from flat metal stock, to redirect water at roof perimeters and edges, and are used in valleys and drainage spillways.

- Manual

- means the Roofing Practices Manual.

- Project

- means the scope of work for which the Contractor is responsible.

- System

- means the organization and securement of various interacting materials (apart from the supporting deck structure), designed and installed to prevent the transmission of water through the system into the conditioned space of a building (adapted from ASTM D6630-08 Standard Guide for Low slope Insulated Roof membrane Assembly Performance).

- Waterproofing system

- means a sheet membrane or liquid-applied system that, regardless of slope, excludes water from a building and therefore waterproofs it. These systems are typically installed on slopes less than 1:4 (3” in 12”), on roofs or at grade level.

- Water-shedding system

- means a roof system that, with sufficient slope, sheds water away from a structure but does not necessarily waterproof it.

Refer to the Glossary for further definitions of key terms used in this Manual.

3 Design

3.1 RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year (Waterproofing Roofs) Guarantee, the following standards apply:

- Each project must be designed and constructed in compliance with both the RoofStar Guarantee Standards, together with the membrane manufacturer’s available 20-year System Warranty standards.

- Where enhanced roof system securement is required by the manufacturer, which may exceed the securement required in a Tested Assembly, an Assembly with Proven Past Performance or a custom-engineered securement, the project must comply with the higher securement requirements.

- In addition to the above, other requirements in this Standard apply, which can be summarized (without limitation) as follows:

- Roofs must be designed for adequate access to facilitate maintenance ( 1.3.3).

- Materials left in place for partial roof system replacement must be scanned for moisture ( 1.4.2.2).

- All roofs (new construction and replacement roofing) must be built with a minimum slope of 2% (1:50) ( 2.2.2 and 2.2.3).

- All replacement roofing must utilize crickets to enhance drainage around curbs and sleepers ( 2.2.3).

- Curbs and sleepers wider/longer than 1200 mm (48") must incorporate crickets to improve drainage ( 7.1.2.1).

- An insulation overlay is required on all Conventionally Insulated Roof Systems ( 8.1.1.1).

- Only certain membranes will qualify for a RoofStar 15-year Guarantee ( 9.2).

- All drains and overflows require clamping rings, and overflows are required for each roof area ( 11.1.2.1).

- Enhanced penetration flashing requirements ( 11.1.3.1).

- Linear metal flashings must be fabricated from 24-gauge material ( 13.1.2.1).

3.2 System Types

Designing a good roof begins with the end in mind and an answer to the essential question, “What purpose will the roof serve?” For example, the roof may

- simply weatherproof the building interior.

- provide a location for building equipment and services.

- support liveable spaces.

Each of these functions may limit the choice of membrane assembly.

There are four principal waterproofing assemblies used on roofs:

- Uninsulated Systems(insulation may be installed beneath the deck).

- Conventionally Insulated Systems (sometimes referred to as Compact Roofs).

- Protected Membrane Roof Systems (also referred to as “inverted”).

- Modified Protected Membrane Roof Systems.

Of course, sometimes the roof deck influences these choices. Regardless of the Design Authority’s starting point, knowing where you are going is the beginning of a successful design.

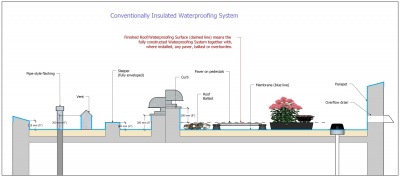

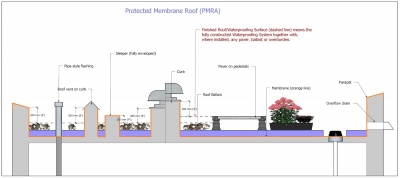

Regardless of the system type, the Finished waterproofing system is defined by whatever is placed on the membrane, which may be insulation, ballast, pavers or overburden. These materials will displace water and therefore affect the height of membrane flashing needed to prevent water ingress. The definition of Finished waterproofing system is illustrated below in Figures 1.3.2-1 and 1.3.2-2. See also 1.2 Definitions.

3.2.1 Conventionally Insulated Waterproofing Systems

- In a Conventionally Insulated Waterproofing System, the membrane is the final layer, exposed to the weather. It protects the other roofing components, including insulation, from exposure to water, wind and other weather conditions. Conventionally Insulated Waterproofing System are classified in this Manual by three different methods of attachment (securement) to the roof deck:

- Mechanically Attached Roof Systems (MARS)

- Partially Adhered Roof Systems (PARS)

- Adhesive Applied Roof Systems (AARS)

More about these three systems is offered in Part 3 SECURING the ROOF ASSEMBLY.

3.2.2 Protected and Modified Protected Membrane Roof Systems

NOTE: See more information on Protected and Modified Protected Roof Systems in Division B: Essential Elements.

- In a Protected Membrane Roof System (or Protected Membrane Roof Assembly, also called PMRA) the membrane is applied directly to the supporting deck structure or the deck overlay (as required and/or specified), and protected from both the elements and damage with insulation and an overburden. In this way, the membrane functions both to waterproof the roof and control air or vapour. Only RoofStar-accepted extruded expanded polystyrene (XPS, conforming to CAN / CGSB-51.20-M87, Type 4) is acceptable for a PMRA. XPS is water-resistant (i.e. resistance to water absorption, moisture transfer, and capillary action), freeze-thaw cycling resistant, and possesses a high compressive strength. If a drainage layer is specified, it is typically installed between the membrane and insulation. An additional drainage layer may be installed above the insulation, together with a filter fabric mat and ballast or overburden. These three components - a drainage layer, filter fabric and ballast - promote controlled drainage, resist infiltration of contaminants, resist the lifting forces of wind, and counteract the natural buoyancy of the insulation.

- PMRAs are the required roof assembly design for certain types of overburden. See 14.1.2 Design for RoofStar Guarantee Standards.

- A Modified Protected Membrane Roof System (or Modified Protected Membrane Roof Assembly, also called MPMRA) is similar to a PMRA except that that insulation is installed both below and above the membrane. This may offer cost savings as only the top layer of insulation requires ballast and the bottom layer (mechanically fastened or adhered) need not be extruded expanded polystyrene and may be tapered to provide slope. As a general rule, two-thirds or more of the total thermal resistance (RSI or R value) should be above the membrane, but in all cases the Design Authority should perform the required psychrometric calculations before designing a roof system.

3.3 Accessibility for Maintenance

3.3.1 RoofStar 15-Year Guarantee

- On all "new construction" projects, where external access is not provided, all roofs with a field elevation greater than 7500 mm (25’) above grade must incorporate safe, appropriate access to the roof, for example by incorporating stairs and a doorway or a properly located roof hatch. These requirements are recommended for existing buildings to facilitate maintenance and ongoing performance reviews.

3.3.2 All Projects

While the RoofStar Guarantee Standards pertain to the design and construction of a leak-free roof, accessible design is still critical since a roof must be regularly maintained. Therefore, while the following list is not exhaustive, the Design Authority is urged to consider these guiding principles when designing a roof project.

- All roofs with a field elevation greater than 7500 mm (25’) above grade should incorporate access to the roof by stairs and a doorway or with a properly located roof hatch.

- Any hatch, ladder or mechanical unit should be located a sufficient distance away from the roof edge (setback zone) so that other fall protection measures are not required by those using or accessing this equipment. When it is not possible to situate a hatch, ladder or mechanical unit outside the setback zone, guard rails should be designed for the roof edge to provide additional fall protection for those using or accessing such equipment.

- Each roof should be designed to provide safe access for maintenance of roof drains, corners or mechanical equipment, where the roof is at least 3 m (10’) above the surface of the ground, or where a hazard to a person exists, should a fall be possible. This principle also applies to roof areas intended for regular occupancy. Therefore, provide fall protection in compliance with the Code having jurisdiction, and with the Workers Compensation Act Regulations, by designing appropriately located

- tall parapets.

- guardrails.

- tie-off anchors.

3.4 Waterproofing Integrity Scans and Electronic Leak Detection

An integrity scan is performed after the installation of the roof waterproofing system, before any overburden, equipment or amenity space is installed on top of it. An integrity scan typically uses low-voltage electrical current to detect even the smallest breaches in the roof membrane, but some waterproofing materials may require the use of other technologies to verify the roof system’s integrity. Therefore, Design Authority should specify the appropriate technology, keeping in mind the limitations of each scan and detection methodology, and of the membranes that are specified.

Electronic Leak Detection (ELD) utilizes low-voltage electrical current, typically conducted through wires installed in a grid pattern. ELD technologies are used in response to a leak, to isolate its location in order to minimize investigation time and material removal. This can benefit a building owner who will have to bear the costs of demolition or overburden removal when the standard limits of coverage afforded by the RoofStar Guarantee are exceeded by the Project design and construction. ELD technologies may be passive (installed but not monitored) or actively monitored (by the installer, through real-time data collection).

- Flood testing (as an alternative to an integrity scan) is not recommended. When flood testing is specified, testing shall be conducted prior to installation of insulation and roof coverings, and must be performed following the methodologies in ASTM D5957.

- Neither an integrity scan nor an Electronic Leak Detection (ELD) system are considered Accepted Materials, but firms that provide these services are nevertheless specifically recognized and approved by the RoofStar Guarantee Program.

- An integrity scan is required for some projects (see 1.6 RoofStar Guarantee: Coverage and Limitations), but is nevertheless strongly recommended before the completed roof assembly is covered with overburden, equipment or living (amenity) spaces (see 14.1.2.1).

- Electronic Leak Detection is required for all grade-level waterproofing systems, and while it is optional for roof waterproofing systems, ELD is strongly recommended

- for projects where multiple trades will have access to a roof that is under construction and completed, in order to identify breaches in the waterproofing membrane in a timely way and avoid future costly delays.

- when the roof assembly protects a sensitive occupied space (i.e. data centres, hospitals, critical infrastructure).

- when the roof supports any type of overburden, equipment or living (amenity) space.

- When Electronic Leak Detection is specified, it should provide detection capabilities for all waterproofed surfaces, and should extend at least 50 mm (2") vertically from the water plane at

- all transitions.

- any point along the entire deck perimeter.

- protrusions.

3.5 Hot Works: Design

When any portion of a waterproofing system is installed with heat, the work is classified as Hot Works. Some tools used in the course of Hot Works can ignite combustible materials, and some building environments are more sensitive to fire than others, such as a building containing or in close proximity to flammable liquids. Hot works may occur during

- tear off (sparks).

- deck preparation (drying wet surfaces).

- cold temperatures (warming materials or surfaces).

- equipment use (sparks within electrical tools, or from cutting, drilling or grinding metal, concrete, stone or other hard surface products).

- membrane installation (with the means of a kettle, hot-air welder or open flame torch).

- The Design Authority may specify that the Contractor must maintain compliance with the RCABC Hot Works Program and consequently manage the Hot Works conducted on site.

- When the Project involves Hot Work, the Design Authority must either

- pre-approve alternate applications already written in this Standard or another applicable Standard published in this Manual, when the specified application is deemed to be fire sensitive by the Contractor as part of the risk assessment process, or

- provide alternate material and application requirements in the Specification for fire sensitive locations on the Project.

See also 1.4.3 Hot Works.

3.6 Variances

When a design is unable to conform to the Standard, the Design Authority may apply to the RGC for a written Variance. Application must be made in writing (email correspondence is common), and the request must

- identify the project name, its civic address and the applicable RoofStar Guarantee number (if already initiated).

- articulate the nature of the design problem.

- cite the RoofStar Guarantee standard reference to which the Variance will apply.

- provide design drawings (and photographs, if available) as supporting information.

We may ask for more information in order to fully consider a request for a Variance and will issue a completed Variance only to the Design Authority for distribution to the Contractor.

A Variance may be unrestricted in its scope, or it may include one or more conditions that will affect the design and construction of the water-shedding system or waterproofing system, in order to accommodate the varied standard. Occasionally, a Variance may also restrict coverage offered by the RoofStar Guarantee.

Variances are issued only for the specific issue on the project identified in the written request, and do not constitute general permission to depart from the published requirements in this Standard, for any aspect of the same project or for future projects, designed or constructed by any other firm.

4 Scope

- The Guarantee Standards, Guiding Principles, Recommendations and Reference Materials in this Standard pertain to both new roofing construction and replacement roofing, unless explicitly stated otherwise.

4.1 New Construction

- New roof construction must utilize only newly manufactured materials, and may not incorporate recycled products, unless with the expressed, written consent of the Guarantor.

4.2 Replacement Roofing and Additions

As a roof ages, is neglected or is damaged, it may lose its ability to perform reliably and effectively, necessitating replacement. Replacement roofing, also referred to as "re-roofing," whether made in whole or in part, should be undertaken with the Quality Assurance and Quality Control provided for under the RoofStar Guarantee Program. Regardless of the approach to replacement roofing, the existing deck structure must meet the pullout resistance rating for mechanical fasteners and must be capable of supporting all dead and live loads. Furthermore, the deck must be capable of supporting any additional dead loads of the new roof system.

Three types of replacement roofing are contemplated and permitted (with varying degrees of limitations and conditions) under the RoofStar Guarantee Program:

- System replacement - removal and replacement of all roof system components, except for the supporting deck structure.

- Membrane replacement – removal and replacement of the roof membrane, while retaining existing roof system components (i.e. insulation, ballast).

- Recovering - installation of a new membrane over an existing membrane, while retaining some or all of the other roof system materials (NOTE: Recovering is permitted only with a written Variance issued by the Guarantor).

Qualifying and construction conditions and limitations for each of these replacement options are described below. Other conditions and limitation may be determined by the Guarantor subject to the nature and specifications of the replacement roofing project.

4.2.1 System Replacement

- Roof system replacement means the complete removal and replacement of all roof system and metal flashing materials, exclusive of the air or vapour control layers (see 1.4.2.1 (2) below). Only new replacement materials are permissible. The design of the replacement roof system, and the installation of new materials, must conform to the RoofStar Guarantee Standards for new roof construction, unless expressly varied elsewhere in this Standard (see, for example, alternate slope requirements and recommendations in 2.2.3 Replacement Roofing).

- Subject to the requirements in 6 AIR and VAPOUR CONTROLS, the decision to reuse and repair an existing air or vapour control layer remains the responsibility of the Design Authority.

- Roof system replacement projects are eligible to qualify for a RoofStar 5-year Guarantee, RoofStar 10-year Guarantee, or RoofStar 15-year Guarantee.

4.2.2 Membrane Replacement

4.2.2.1 RoofStar 15-Year Guarantee

- In addition to the General Requirements for Membrane Replacement outlined below, a project designed to qualify for a RoofStar 15-year Guarantee must

- be supported by the following, submitted in report form to the Guarantor for review and consideration prior to tender:

- moisture survey scan performed by a qualified person.

- at least three (3) cut tests for roof areas up to 20,000 sf (200 squares), or one (1) cut test for every 2000 sf (20 squares), whichever is more.

- one (1) cut test for every 3000 sf (30 squares) of roof area that exceeds the first 20,000 sf (200 squares).

- one (1) cut test for each small roof area measuring no more than 200 sf (2 squares).

- incorporate new insulation overlays in keeping with the requirements published in Part 8 INSULATION OVERLAYS.

- be supported by the following, submitted in report form to the Guarantor for review and consideration prior to tender:

4.2.2.2 General Requirements

Membrane replacement is a partial roof system replacement, limited to the membrane or materials adhered to the membrane. A written Variance is not needed for this type of project, but for membrane replacement to qualify for a RoofStar Guarantee,

- the Design Authority must be certain the existing roof system is properly secured to the existing deck structure (see Part 3 SECURING the ROOF ASSEMBLY).

- the existing roof system must be demonstrably dry and free of any wet materials (wet materials must be replaced, in order to qualify for a RoofStar Guarantee).

- the existing field membrane must be removed and replaced with a new insulation overlay board and a new membrane.

- existing membrane flashing must be removed and replaced with new materials.

- the design must comply with the RoofStar Guarantee Standards for new roof construction.

4.2.3 Recovering

Recovering - installing a new membrane over an existing membrane - is permitted in certain circumstances for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, though it is not a recommended practice and will limit the scope of coverage for the RoofStar Guarantee. Recovering does not qualify for a RoofStar 15-year Guarantee.

Qualifying for a RoofStar Guarantee is subject to the General Conditions and Limitations listed below and is permitted only with a written Variance issued by the Guarantor. A RoofStar Guarantee issued for a recovered roof is limited strictly to the value of new roof system materials; existing materials that remain in place beneath new materials do not qualify for coverage under the RoofStar Guarantee.

The Design Authority should consider the following before proceeding with Recovering a roof:

- Moisture tests (described below).

- Securement test.

- The potential consequences of failure for the building and its use.

4.2.3.1 Recovering: Project Qualifications

Any Variance permitting roof recovering must be applied for in writing by the Design Authority, addressed to the RoofStar Guarantee Program prior to the tendering of documents (see 1.3.6 Variances). To qualify for a Variance, the following conditions must be met and confirmed in the written application:

- The new roof system must be properly secured to the existing deck structure (see Part 3 SECURING the ROOF ASSEMBLY).

- The existing roof system must be distinct and physically separate from other roof areas.

- The request for a Variance must identify the type of roof system - Uninsulated,Conventionally Insulated, Protected Membrane Roof System or Modified Protected Membrane Roof System.

- Uninsulated Systems only: The existing roof system must be free of blisters and breaches in the membrane. Systems constructed on a wood deck must be independently surveyed by qualified professionals using calibrated moisture detection equipment. Moisture detected in a wood deck must be investigated by cutting the membrane and probing the deck for moisture and deterioration. The resulting survey shall be formally documented for review by the Guarantor.

- Conventionally Insulated Systems only: The existing roof system must be independently surveyed by qualified professionals using calibrated moisture detection equipment and cut tests, and the resulting survey shall be formally documented for review by the Guarantor. The following requirements for cut tests apply, based on roof area. All cut tests shall be independently documented for review by the Guarantor:

- At least three (3) cut tests for roof areas up to 20,000 sf (200 squares), or one (1) cut test for every 2000 sf (20 squares), whichever is more.

- One (1) cut test for every 3000 sf (30 squares) of roof area that exceeds the first 20,000 sf (200 squares).

- One (1) cut test for each small roof area measuring no more than 200 sf (2 squares).

- Where the roof has been constructed with a structurally sloped deck, at least 50% of the required cut tests shall sample roof areas in or near valleys, and areas; samples shall also be taken near roof drains.

- Where the roof has been constructed with a structurally flat deck, samples shall be taken near roof drains and in a random pattern across the roof.

- All cut tests for existing SBS-modified membrane roof systems shall be performed to ASTM D7636/D7636M, 11 Standard Practice for Sampling and Analysis of Modified Bitumen Roof Systems.

- Existing Conventionally Insulated Roof Systems constructed with expanded polystyrene insulation (EPS) may qualify for a RoofStar Guarantee, subject to the General Conditions and Limitations below.

4.2.3.2 Recovering: General Conditions and Limitations

In addition to the RoofStar Guarantee Standards found in this Manual, the following additional requirements and conditions apply:

- All wet material identified by either the independent moisture detection survey or through cut tests shall be

- specified for removal.

- removed in the course of construction.

- Uninsulated Systems:

- Deteriorated wood decks must be repaired with new material of like kind and quality. A new roof system shall not be installed on a compromised deck.

- The existing membrane system must be

- clean and free of debris, gravel, or blisters.

- cut at the perimeter change in plane to relieve any tension or distortions in the membrane.

- The existing field and flashing membranes must be overlaid with a mechanically attached insulation overlay board acceptable to the Guarantor. Notwithstanding this requirement, only non-organic and moisture-resistant overlay boards may be used in the project. Securement must conform to the requirements in Part 3, Section 3.

- Conventionally Insulated Systems: the existing membrane must be cut through

- in a grid pattern measuring no larger than 6m x 6m (approximately 20' x 20').

- around the perimeter of the roof area, no more than 0.2 m (8") from the edge.

- A grid-cut field membrane must be overlaid with a mechanically attached insulation overlay board acceptable to the Guarantor; notwithstanding this requirement, only non-organic and moisture-resistant overlay boards may be used in the project.

- When expanded polystyrene insulation (EPS) is present in an existing roof system, the existing membrane must be overlaid with at least one layer of 50 mm (2”) mineral wool or polyisocyanurate insulation, in combination with a RoofStar-accepted insulation overlay board (as required).

- New membranes must be properly secured to the underlying roof assembly.

- Only new strip-in flashings for roof penetrations are acceptable for a RoofStar Guarantee; reusing existing flashings is not permitted.

- Only new roof drains are acceptable for a RoofStar Guarantee, and under no circumstances shall existing roof drains be reused. Cast-iron roof drains in usable condition are exempted from this Standard (see 11.1.2.2(3)).

- Only new linear metal flashings are acceptable for installation at perimeters or at membrane terminations, and under no circumstances shall existing linear metal flashings be reused.

4.2.4 Tie-ins and Additions to Existing Roofing

- Where a new roof adjoins and ties into an existing roof, the two areas must be isolated and separated by a curb joint securely attached to the structure and waterproofed in keeping with the requirements in 2.5 Control Joints and Part 10 PERIMETERS and WALLS.

- If project conditions do not allow for a curb joint, the Design Authority must obtain a written Variance from the Guarantor that permits the elimination of curb joints. Application for a Variance must include design specifications and construction details showing a positive water cut-off that fully isolates the existing roof from the new roof. In the absence of a curb joint, the new roof system must be easily distinguishable from the existing roof system.

4.3 Hot Works: Contractor Requirements

- The Contractor must maintain the requirements of the RCABC Hot Works Program. This includes the following, without limitation:

- Insurance Coverage – limits carried on the Contractor’s policy must equal or exceed the minimum requirements set by RCABC, and coverage must be unhindered by warranties that limit or exclude coverage when Hot Works is required.

- Education and training – workers who perform Hot Works must be trained by the Contractor and kept current with acceptable methods.

- British Columbia Fire Code – a Fire Safety Plan, preventative methods or alternative work procedures, fire watches, and the use and placement of equipment at the project site must comply with the BC Fire Code requirements for Hot Work.

- Fire Safety Plan – the Contractor must assess the hazards to property and persons and produce a written Fire Safety Plan prior to the start of work. The Fire Safety Plan must be kept on the Project site and must be kept current until the project is completed.

- RoofStar Guarantee Standards – the Contractor must adhere to the RoofStar Guarantee Standards at each juncture where the interface of different membranes applications constitutes part of the Fire Safety Plan.

- Fire Watch – the Contractor must, as part of the Fire Safety Plan, conduct a fire watch

- that complies with the British Columbia Fire Code.

- assigned to competent, trained personnel using suitable equipment, including the use of a hand-held infrared thermometer.

- documented in a written fire watch log.

- Hot Works Notification – notify the project authority or the AHJ, as and when required, that Hot Works will be performed.

5 Workmanship

While integrity and functionality of a new roof or grade-level waterproofing is the foundation of a RoofStar Guarantee, it is no less important to ensure that the finished project exhibits excellent workmanship. Therefore, the following Standards apply:

- The Contractor must take reasonable measures to protect the project from damage by the weather, during and at the completion of the project. Open penetrations and flashings must be temporarily sealed off from the weather, even when other trades are responsible to make a permanent seal or install overlapping materials. See also 4.2 General.

5.1 Contractor Qualifications

- Supervision and installation of a RoofStar-guaranteed roof waterproofing system may be conducted only by established employees of the Contractor, and every project must be supervised by a Journeyperson employee who holds a valid ticket. In keeping with RCABC Membership policy, a Journeyperson may supervise a maximum of three (3) apprentices and/or three (3) labourers (ref. RCABC Policy A-248, Rev. 5 April 2019).

6 RoofStar Guarantee: Coverage and Limitations

- Coverage under the RoofStar Guarantee shall be as described in Division A, Part 3, Article 3.2.1.2.

1 References

In this Manual, all references to

- the British Columbia Building Code, municipal or regional building codes or regulations (collectively referred to as the “Code”), or other standards, presume the current edition that is in force.

- materials are assumed to be Accepted by the RGC, unless stated otherwise.

2 Definitions

- Assembly

- means a system in combination with its supporting deck structure (adapted from ASTM D6630-08 Standard Guide for Low slope Insulated Roof membrane Assembly Performance).

- Contractor

- means the installer of a project. For the purpose of issuing a RoofStar Guarantee, Contractor shall be read to mean an Active Member of the RCABC.

- Design Authority

- means the individual or firm responsible for the issuance of Project specifications and details to which the Project will be bid and constructed. When a Contractor designs a Project, the Contractor is deemed to be the Design Authority.

- Finished waterproofing/water-shedding system

- means the top surface of a waterproofing system or water-shedding system that may include ballast or that supports overburden.

- Guarantor

- means the RGC RoofStar Guarantee Program that issues the RoofStar Guarantee ("Guarantee"); the two terms may be used interchangeably.

- Linear metal flashings

- are flashings cut and shaped from flat metal stock, to redirect water at roof perimeters and edges, and are used in valleys and drainage spillways.

- Manual

- means the Roofing Practices Manual.

- Project

- means the scope of work for which the Contractor is responsible.

- System

- means the organization and securement of various interacting materials (apart from the supporting deck structure), designed and installed to prevent the transmission of water through the system into the conditioned space of a building (adapted from ASTM D6630-08 Standard Guide for Low slope Insulated Roof membrane Assembly Performance).

- Waterproofing system

- means a sheet membrane or liquid-applied system that, regardless of slope, excludes water from a building and therefore waterproofs it. These systems are typically installed on slopes less than 1:4 (3” in 12”), on roofs or at grade level.

- Water-shedding system

- means a roof system that, with sufficient slope, sheds water away from a structure but does not necessarily waterproof it.

Refer to the Glossary for further definitions of key terms used in this Manual.

3 Design

3.1 RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year (Waterproofing Roofs) Guarantee, the following standards apply:

- Each project must be designed and constructed in compliance with both the RoofStar Guarantee Standards, together with the membrane manufacturer’s available 20-year System Warranty standards.

- Where enhanced roof system securement is required by the manufacturer, which may exceed the securement required in a Tested Assembly, an Assembly with Proven Past Performance or a custom-engineered securement, the project must comply with the higher securement requirements.

- In addition to the above, other requirements in this Standard apply, which can be summarized (without limitation) as follows:

- Roofs must be designed for adequate access to facilitate maintenance ( 1.3.3).

- Materials left in place for partial roof system replacement must be scanned for moisture ( 1.4.2.2).

- All roofs (new construction and replacement roofing) must be built with a minimum slope of 2% (1:50) ( 2.2.2 and 2.2.3).

- All replacement roofing must utilize crickets to enhance drainage around curbs and sleepers ( 2.2.3).

- Curbs and sleepers wider/longer than 1200 mm (48") must incorporate crickets to improve drainage ( 7.1.2.1).

- An insulation overlay is required on all Conventionally Insulated Roof Systems ( 8.1.1.1).

- Only certain membranes will qualify for a RoofStar 15-year Guarantee ( 9.2).

- All drains and overflows require clamping rings, and overflows are required for each roof area ( 11.1.2.1).

- Enhanced penetration flashing requirements ( 11.1.3.1).

- Linear metal flashings must be fabricated from 24-gauge material ( 13.1.2.1).

3.2 System Types

Designing a good roof begins with the end in mind and an answer to the essential question, “What purpose will the roof serve?” For example, the roof may

- simply weatherproof the building interior.

- provide a location for building equipment and services.

- support liveable spaces.

Each of these functions may limit the choice of membrane assembly.

There are four principal waterproofing assemblies used on roofs:

- Uninsulated Systems(insulation may be installed beneath the deck).

- Conventionally Insulated Systems (sometimes referred to as Compact Roofs).

- Protected Membrane Roof Systems (also referred to as “inverted”).

- Modified Protected Membrane Roof Systems.

Of course, sometimes the roof deck influences these choices. Regardless of the Design Authority’s starting point, knowing where you are going is the beginning of a successful design.

Regardless of the system type, the Finished waterproofing system is defined by whatever is placed on the membrane, which may be insulation, ballast, pavers or overburden. These materials will displace water and therefore affect the height of membrane flashing needed to prevent water ingress. The definition of Finished waterproofing system is illustrated below in Figures 1.3.2-1 and 1.3.2-2. See also 1.2 Definitions.

3.2.1 Conventionally Insulated Waterproofing Systems

- In a Conventionally Insulated Waterproofing System, the membrane is the final layer, exposed to the weather. It protects the other roofing components, including insulation, from exposure to water, wind and other weather conditions. Conventionally Insulated Waterproofing System are classified in this Manual by three different methods of attachment (securement) to the roof deck:

- Mechanically Attached Roof Systems (MARS)

- Partially Adhered Roof Systems (PARS)

- Adhesive Applied Roof Systems (AARS)

More about these three systems is offered in Part 3 SECURING the ROOF ASSEMBLY.

3.2.2 Protected and Modified Protected Membrane Roof Systems

NOTE: See more information on Protected and Modified Protected Roof Systems in Division B: Essential Elements.

- In a Protected Membrane Roof System (or Protected Membrane Roof Assembly, also called PMRA) the membrane is applied directly to the supporting deck structure or the deck overlay (as required and/or specified), and protected from both the elements and damage with insulation and an overburden. In this way, the membrane functions both to waterproof the roof and control air or vapour. Only RoofStar-accepted extruded expanded polystyrene (XPS, conforming to CAN / CGSB-51.20-M87, Type 4) is acceptable for a PMRA. XPS is water-resistant (i.e. resistance to water absorption, moisture transfer, and capillary action), freeze-thaw cycling resistant, and possesses a high compressive strength. If a drainage layer is specified, it is typically installed between the membrane and insulation. An additional drainage layer may be installed above the insulation, together with a filter fabric mat and ballast or overburden. These three components - a drainage layer, filter fabric and ballast - promote controlled drainage, resist infiltration of contaminants, resist the lifting forces of wind, and counteract the natural buoyancy of the insulation.

- PMRAs are the required roof assembly design for certain types of overburden. See 14.1.2 Design for RoofStar Guarantee Standards.

- A Modified Protected Membrane Roof System (or Modified Protected Membrane Roof Assembly, also called MPMRA) is similar to a PMRA except that that insulation is installed both below and above the membrane. This may offer cost savings as only the top layer of insulation requires ballast and the bottom layer (mechanically fastened or adhered) need not be extruded expanded polystyrene and may be tapered to provide slope. As a general rule, two-thirds or more of the total thermal resistance (RSI or R value) should be above the membrane, but in all cases the Design Authority should perform the required psychrometric calculations before designing a roof system.

3.3 Accessibility for Maintenance

3.3.1 RoofStar 15-Year Guarantee

- On all "new construction" Projects, where external access is not provided, all roofs with a field elevation greater than 7500 mm (25’) above grade must incorporate safe, appropriate access to the roof, for example by incorporating stairs and a doorway or a properly located roof hatch. These requirements are recommended for existing buildings to facilitate maintenance and ongoing performance reviews.

3.3.2 All Projects

While the RoofStar Guarantee Standards pertain to the design and construction of a leak-free roof, accessible design is still critical since a roof must be regularly maintained. Therefore, while the following list is not exhaustive, the Design Authority is urged to consider these guiding principles when designing a roof Project.

- All roofs with a field elevation greater than 7500 mm (25’) above grade should incorporate access to the roof by stairs and a doorway or with a properly located roof hatch.

- Any hatch, ladder or mechanical unit should be located a sufficient distance away from the roof edge (setback zone) so that other fall protection measures are not required by those using or accessing this equipment. When it is not possible to situate a hatch, ladder or mechanical unit outside the setback zone, guard rails should be designed for the roof edge to provide additional fall protection for those using or accessing such equipment.

- Each roof should be designed to provide safe access for maintenance of roof drains, corners or mechanical equipment, where the roof is at least 3 m (10’) above the surface of the ground, or where a hazard to a person exists, should a fall be possible. This principle also applies to roof areas intended for regular occupancy. Therefore, provide fall protection in compliance with the Code having jurisdiction, and with the Workers Compensation Act Regulations, by designing appropriately located

- tall parapets.

- guardrails.

- tie-off anchors.

3.4 Waterproofing Integrity Scans and Electronic Leak Detection

An integrity scan is performed after the installation of the roof waterproofing system, before any overburden, equipment or amenity space is installed on top of it. An integrity scan typically uses low-voltage electrical current to detect even the smallest breaches in the roof membrane, but some waterproofing materials may require the use of other technologies to verify the roof system’s integrity. Therefore, Design Authority should specify the appropriate technology, keeping in mind the limitations of each scan and detection methodology, and of the membranes that are specified.

Electronic Leak Detection (ELD) utilizes low-voltage electrical current, typically conducted through wires installed in a grid pattern. ELD technologies are used in response to a leak, to isolate its location in order to minimize investigation time and material removal. This can benefit a building owner who will have to bear the costs of demolition or overburden removal when the standard limits of coverage afforded by the RoofStar Guarantee are exceeded by the Project design and construction. ELD technologies may be passive (installed but not monitored) or actively monitored (by the installer, through real-time data collection).

- Flood testing (as an alternative to an integrity scan) is not recommended. When flood testing is specified, testing shall be conducted prior to installation of insulation and roof coverings, and must be performed following the methodologies in ASTM D5957.

- Neither an integrity scan nor an Electronic Leak Detection (ELD) system are considered Accepted Materials, but firms that provide these services are nevertheless specifically recognized and approved by the RoofStar Guarantee Program.

- An integrity scan is required for some projects (see 1.6 RoofStar Guarantee: Coverage and Limitations), but is nevertheless strongly recommended before the completed roof assembly is covered with overburden, equipment or living (amenity) spaces (see 14.1.2.1).

- Electronic Leak Detection is required for all grade-level waterproofing systems, and while it is optional for roof waterproofing systems, ELD is strongly recommended

- for projects where multiple trades will have access to a roof that is under construction and completed, in order to identify breaches in the waterproofing membrane in a timely way and avoid future costly delays.

- when the roof assembly protects a sensitive occupied space (i.e. data centres, hospitals, critical infrastructure).

- when the roof supports any type of overburden, equipment or living (amenity) space.

- When Electronic Leak Detection is specified, it should provide detection capabilities for all waterproofed surfaces, and should extend at least 50 mm (2") vertically from the water plane at

- all transitions.

- any point along the entire deck perimeter.

- protrusions.

3.5 Hot Works: Design

When any portion of a waterproofing system is installed with heat, the work is classified as Hot Works. Some tools used in the course of Hot Works can ignite combustible materials, and some building environments are more sensitive to fire than others, such as a building containing, or close to, flammable liquids. Hot Works may occur during

- tear off (sparks).

- deck preparation (drying wet surfaces).

- cold temperatures (warming materials or surfaces).

- equipment use (sparks within electrical tools, or from cutting, drilling or grinding metal, concrete, stone or other hard surface products).

- The Design Authority may specify that the Contractor must maintain compliance with the RCABC Hot Works Program and consequently manage the Hot Works conducted on site.

- When the Project involves Hot Works, the Design Authority must either

- pre-approve alternate applications already written within the Manual when the specified application is deemed to be fire-sensitive by the Contractor as part of the risk assessment process.

- provide alternate material and application requirements in the specification for fire-sensitive locations on the project.

See also 1.4.3 Hot Works

- Contractor Requirements.

3.6 Variances

When a design is unable to conform to the Standard, the Design Authority may apply to the RGC for a written Variance. Application must be made in writing (email correspondence is common), and the request must

- identify the project name, its civic address and the applicable RoofStar Guarantee number (if already initiated).

- articulate the nature of the design problem.

- cite the RoofStar Guarantee standard reference to which the Variance will apply.

- provide design drawings (and photographs, if available) as supporting information.

We may ask for more information in order to fully consider a request for a Variance and will issue a completed Variance only to the Design Authority for distribution to the Contractor.

A Variance may be unrestricted in its scope, or it may include one or more conditions that will affect the design and construction of the water-shedding system or waterproofing system, in order to accommodate the varied standard. Occasionally, a Variance may also restrict coverage offered by the RoofStar Guarantee.

Variances are issued only for the specific issue on the project identified in the written request, and do not constitute general permission to depart from the published requirements in this Standard, for any aspect of the same project or for future projects, designed or constructed by any other firm.

4 Scope

- The Guarantee Standards, Guiding Principles, Recommendations and Reference Materials in this Standard pertain to both new roofing construction and replacement roofing, unless explicitly stated otherwise.

4.1 New Construction

- New roof construction must utilize only newly manufactured materials, and may not incorporate recycled products, unless with the expressed, written consent of the Guarantor.

4.2 Replacement Roofing and Additions

As a roof ages, is neglected or is damaged, it may lose its ability to perform reliably and effectively, necessitating replacement. Replacement roofing, also referred to as "re-roofing," whether made in whole or in part, should be undertaken with the Quality Assurance and Quality Control provided for under the RoofStar Guarantee Program. Regardless of the approach to replacement roofing, the existing deck structure must meet the pullout resistance rating for mechanical fasteners and must be capable of supporting all dead and live loads. Furthermore, the deck must be capable of supporting any additional dead loads of the new roof system.

Three types of replacement roofing are contemplated and permitted (with varying degrees of limitations and conditions) under the RoofStar Guarantee Program:

- System replacement - removal and replacement of all roof system components, except for the supporting deck structure.

- Membrane replacement – removal and replacement of the roof membrane, while retaining existing roof system components (i.e. insulation, ballast).

- Recovering - installation of a new membrane over an existing membrane, while retaining some or all of the other roof system materials (NOTE: Recovering is permitted only with a written Variance issued by the Guarantor).

Qualifying and construction conditions and limitations for each of these replacement options are described below. Other conditions and limitation may be determined by the Guarantor subject to the nature and specifications of the replacement roofing project.

4.2.1 System Replacement

- Roof system replacement means the complete removal and replacement of all roof system and metal flashing materials, exclusive of the air or vapour control layers (see 1.4.2.1 (2) below). Only new replacement materials are permissible. The design of the replacement roof system, and the installation of new materials, must conform to the RoofStar Guarantee Standards for new roof construction, unless expressly varied elsewhere in this Standard (see, for example, alternate slope requirements and recommendations in 2.2.3 Replacement Roofing).

- Subject to the requirements in 6 AIR and VAPOUR CONTROLS, the decision to reuse and repair an existing air or vapour control layer remains the responsibility of the Design Authority.

- Subject to the requirements in 6 AIR and VAPOUR CONTROLS, the decision to reuse and repair an existing air or vapour control layer remains the responsibility of the Design Authority.

- Roof system replacement projects are eligible to qualify for a RoofStar 5-year Guarantee, RoofStar 10-year Guarantee, or RoofStar 15-year Guarantee.

4.2.2 Membrane Replacement

4.2.2.1 RoofStar 15-Year Guarantee

- In addition to the General Requirements for Membrane Replacement outlined below, a project designed to qualify for a RoofStar 15-year Guarantee must

- be supported by the following, submitted in report form to the Guarantor for review and consideration prior to tender:

- moisture survey scan performed by a qualified person.

- at least three (3) cut tests for roof areas up to 20,000 sf (200 squares), or one (1) cut test for every 2000 sf (20 squares), whichever is more.

- one (1) cut test for every 3000 sf (30 squares) of roof area that exceeds the first 20,000 sf (200 squares).

- one (1) cut test for each small roof area measuring no more than 200 sf (2 squares).

- incorporate new insulation overlays in keeping with the requirements published in Part 8 INSULATION OVERLAYS.

- be supported by the following, submitted in report form to the Guarantor for review and consideration prior to tender:

4.2.2.2 General Requirements

Membrane replacement is a partial roof system replacement, limited to the membrane or materials adhered to the membrane. A written Variance is not needed for this type of project, but for membrane replacement to qualify for a RoofStar Guarantee,

- the Design Authority must be certain the existing roof system is properly secured to the existing deck structure (see Part 3 SECURING the ROOF ASSEMBLY).

- the existing roof system must be demonstrably dry and free of any wet materials (wet materials must be replaced, in order to qualify for a RoofStar Guarantee).

- the existing field membrane must be removed and replaced with a new insulation overlay board and a new membrane.

- existing membrane flashing must be removed and replaced with new materials.

- the design must comply with the RoofStar Guarantee Standards for new roof construction.

4.2.3 Recovering

Recovering - installing a new membrane over an existing membrane - is permitted in certain circumstances for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, though it is not a recommended practice and will limit the scope of coverage for the RoofStar Guarantee. Recovering does not qualify for a RoofStar 15-year Guarantee.

Qualifying for a RoofStar Guarantee is subject to the General Conditions and Limitations listed below and is permitted only with a written Variance issued by the Guarantor. A RoofStar Guarantee issued for a recovered roof is limited strictly to the value of new roof system materials; existing materials that remain in place beneath new materials do not qualify for coverage under the RoofStar Guarantee.

4.2.3.1 Recovering: Project Qualifications

Any Variance permitting roof recovering must be applied for in writing by the Design Authority, addressed to the RoofStar Guarantee Program prior to the tendering of documents. To qualify for a Variance, the following conditions must be met and confirmed in the written application:

- The new roof system must be properly secured to the existing deck structure (see Part 3 SECURING the ROOF ASSEMBLY).

- The existing roof system must be distinct and physically separate from other roof areas.

- The request for a Variance must identify the type of roof system - Conventionally Insulated, Protected Membrane Roof System or Modified Protected Membrane Roof System.

- Conventionally Insulated Systems only: The existing roof system must be independently surveyed by qualified professionals using calibrated moisture detection equipment and cut tests, and the resulting survey shall be formally documented for review by the Guarantor. The following requirements for cut tests apply, based on roof area. All cut tests shall be independently documented for review by the Guarantor:

- At least three (3) cut tests for roof areas up to 20,000 sf (200 squares), or one (1) cut test for every 2000 sf (20 squares), whichever is more.

- One (1) cut test for every 3000 sf (30 squares) of roof area that exceeds the first 20,000 sf (200 squares).

- One (1) cut test for each small roof area measuring no more than 200 sf (2 squares).

- Where the roof has been constructed with a structurally sloped deck, at least 50% of the required cut tests shall sample roof areas in or near valleys, and areas; samples shall also be taken near roof drains.

- Where the roof has been constructed with a structurally flat deck, samples shall be taken near roof drains and in a random pattern across the roof.

- All cut tests for existing SBS-modified membrane roof systems shall be performed to ASTM D7636/D7636M, 11 Standard Practice for Sampling and Analysis of Modified Bitumen Roof Systems.

- Existing Conventionally Insulated Roof Systems constructed with expanded polystyrene insulation (EPS) may qualify for a RoofStar Guarantee, subject to the General Conditions and Limitations below.

4.2.3.2 Recovering: General Conditions and Limitations

In addition to the RoofStar Guarantee Standards found in this Manual, the following additional requirements and conditions apply:

- All wet material identified by either the independent moisture detection survey or through cut tests shall be

- specified for removal.

- removed in the course of construction.

- The existing membrane on a Conventionally Insulated System must be cut through

- in a grid pattern measuring no larger than 6m x 6m (approximately 20' x 20').

- around the perimeter of the roof area, no more than 0.2 m (8") from the edge.

- A grid-cut field membrane must be overlaid with a mechanically attached insulation overlay board acceptable to the Guarantor; notwithstanding this requirement, only non-organic and moisture-resistant overlay boards may be used in the Project.

- When expanded polystyrene insulation (EPS) is present in an existing roof system, the existing membrane must be overlaid with at least one layer of 50 mm (2”) mineral wool or polyisocyanurate insulation, in combination with a RoofStar-accepted insulation overlay board (as required).

- New membranes must be properly secured to the underlying roof assembly.

- Only new strip-in flashings for roof penetrations are acceptable for a RoofStar Guarantee; reusing existing flashings is not permitted.

- Only new roof drains are acceptable for a RoofStar Guarantee, and under no circumstances shall existing roof drains be reused. Cast-iron roof drains in usable condition are exempted from this Standard (see 11.1.2.2(3)).

- Only new linear metal flashings are acceptable for installation at perimeters or at membrane terminations, and under no circumstances shall existing linear metal flashings be reused.

4.2.4 Tie-ins and Additions to Existing Roofing

- Where a new roof adjoins and ties into an existing roof, the two areas must be isolated and separated by a curb joint securely attached to the structure and waterproofed in keeping with the requirements in 2.5 Control Joints and Part 10 PERIMETERS and WALLS.

- If project conditions do not allow for a curb joint, the Design Authority must obtain a written Variance from the Guarantor that permits the elimination of curb joints. Application for a Variance must include design specifications and construction details showing a positive water cut-off that fully isolates the existing roof from the new roof. In the absence of a curb joint, the new roof system must be easily distinguishable from the existing roof system.

4.3 Hot Works: Contractor Requirements

- The Contractor must maintain the requirements of the RCABC Hot Works Program. This includes the following, without limitation:

- Insurance Coverage – limits carried on the Contractor’s policy must equal or exceed the minimum requirements set by RCABC, and coverage must be unhindered by warranties that limit or exclude coverage when Hot Works is required.

- Education and training – workers who perform Hot Works must be trained by the Contractor and kept current with acceptable methods.

- British Columbia Fire Code – a Fire Safety Plan, preventative methods or alternative work procedures, fire watches, and the use and placement of equipment at the project site must comply with the BC Fire Code requirements for Hot Work.

- Fire Safety Plan – the Contractor must assess the hazards to property and persons and produce a written Fire Safety Plan prior to the start of work. The Fire Safety Plan must be kept on the Project site and must be kept current until the project is completed.

- RoofStar Guarantee Standards – the Contractor must adhere to the RoofStar Guarantee Standards at each juncture where the interface of different membranes applications constitutes part of the Fire Safety Plan.

- Fire Watch – the Contractor must, as part of the Fire Safety Plan, conduct a fire watch

- that complies with the British Columbia Fire Code.

- assigned to competent, trained personnel using suitable equipment, including the use of a hand-held infrared thermometer.

- documented in a written fire watch log.

- Hot Works Notification – notify the project authority or the AHJ, as and when required, that Hot Works will be performed.

5 Workmanship

While integrity and functionality of a new roof or grade-level waterproofing is the foundation of a RoofStar Guarantee, it is no less important to ensure that the finished project exhibits excellent workmanship. Therefore, the following Standards apply:

- The Contractor must take reasonable measures to protect the project from damage by the weather, during and at the completion of the project. Open penetrations and flashings must be temporarily sealed off from the weather, even when other trades are responsible to make a permanent seal or install overlapping materials. See also 4.2 General.

5.1 Contractor Qualifications

- Supervision and installation of a RoofStar-guaranteed roof waterproofing system may be conducted only by established employees of the Contractor, and every project must be supervised by a Journeyperson employee who holds a valid ticket. In keeping with RCABC Membership policy, a Journeyperson may supervise a maximum of three (3) apprentices and/or three (3) labourers (ref. RCABC Policy A-248, Rev. 5 April 2019).

6 RoofStar Guarantee: Coverage and Limitations

- Coverage under the RoofStar Guarantee shall be as described in Division A, Part 3, Article 3.2.1.2.

1 References

In this Manual, all references to

- the British Columbia Building Code, municipal or regional building codes or regulations (collectively referred to as the “Code”), or other standards, presume the current edition that is in force.

- materials are assumed to be Accepted by the RGC, unless stated otherwise.

2 Definitions

- Assembly

- means a system in combination with its supporting deck structure (adapted from ASTM D6630-08 Standard Guide for Low slope Insulated Roof membrane Assembly Performance).

- Contractor

- means the installer of a project. For the purpose of issuing a RoofStar Guarantee, Contractor shall be read to mean an Active Member of the RCABC.

- Design Authority

- means the individual or firm responsible for the issuance of Project specifications and details to which the Project will be bid and constructed. When a Contractor designs a Project, the Contractor is deemed to be the Design Authority.

- Finished waterproofing/water-shedding system

- means the top surface of a waterproofing system or water-shedding system that may include ballast or that supports overburden.

- Guarantor

- means the RGC RoofStar Guarantee Program that issues the RoofStar Guarantee ("Guarantee"); the two terms may be used interchangeably.

- Linear metal flashings

- are flashings cut and shaped from flat metal stock, to redirect water at roof perimeters and edges, and are used in valleys and drainage spillways.

- Manual

- means the Roofing Practices Manual.

- Project

- means the scope of work for which the Contractor is responsible.

- System

- means the organization and securement of various interacting materials (apart from the supporting deck structure), designed and installed to prevent the transmission of water through the system into the conditioned space of a building (adapted from ASTM D6630-08 Standard Guide for Low slope Insulated Roof membrane Assembly Performance).

- Waterproofing system

- means a sheet membrane or liquid-applied system that, regardless of slope, excludes water from a building and therefore waterproofs it. These systems are typically installed on slopes less than 1:4 (3” in 12”), on roofs or at grade level.

- Water-shedding system

- means a roof system that, with sufficient slope, sheds water away from a structure but does not necessarily waterproof it.

Refer to the Glossary for further definitions of key terms used in this Manual.

3 Design

3.1 RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year (Waterproofing Roofs) Guarantee, the following standards apply:

- Each project must be designed and constructed in compliance with both the RoofStar Guarantee Standards, together with the membrane manufacturer’s available 20-year System Warranty standards.

- Where enhanced roof system securement is required by the manufacturer, which may exceed the securement required in a Tested Assembly, an Assembly with Proven Past Performance or a custom-engineered securement, the project must comply with the higher securement requirements.

- In addition to the above, other requirements in this Standard apply, which can be summarized (without limitation) as follows:

- Roofs must be designed for adequate access to facilitate maintenance ( 1.3.3).

- Materials left in place for partial roof system replacement must be scanned for moisture ( 1.4.2.2).

- All roofs (new construction and replacement roofing) must be built with a minimum slope of 2% (1:50) ( 2.2.2 and 2.2.3).

- All replacement roofing must utilize crickets to enhance drainage around curbs and sleepers ( 2.2.3).

- Curbs and sleepers wider/longer than 1200 mm (48") must incorporate crickets to improve drainage ( 7.1.2.1).

- An insulation overlay is required on all Conventionally Insulated Roof Systems ( 8.1.1.1).

- Only certain membranes will qualify for a RoofStar 15-year Guarantee (9.2).

- All drains and overflows require clamping rings, and overflows are required for each roof area ( 11.1.2.1).

- Enhanced penetration flashing requirements ( 11.1.3.1).

- Linear metal flashings must be fabricated from 24-gauge material ( 13.1.2.1).

3.2 System Types

Designing a good roof begins with the end in mind and an answer to the essential question, “What purpose will the roof serve?” For example, the roof may

- simply weatherproof the building interior.

- provide a location for building equipment and services.

- support liveable spaces.

Each of these functions may limit the choice of membrane assembly.

There are four principal waterproofing assemblies used on roofs:

- Uninsulated Systems(insulation may be installed beneath the deck).

- Conventionally Insulated Systems (sometimes referred to as Compact Roofs).

- Protected Membrane Roof Systems (also referred to as “inverted”).

- Modified Protected Membrane Roof Systems.

Of course, sometimes the roof deck influences these choices. Regardless of the Design Authority’s starting point, knowing where you are going is the beginning of a successful design.

Regardless of the system type, the Finished waterproofing system is defined by whatever is placed on the membrane, which may be insulation, ballast, pavers or overburden. These materials will displace water and therefore affect the height of membrane flashing needed to prevent water ingress. The definition of Finished waterproofing system is illustrated below in Figures 1.3.2-1 and 1.3.2-2. See also 1.2 Definitions.

3.2.1 Conventionally Insulated Waterproofing Systems

- In a Conventionally Insulated Waterproofing System, the membrane is the final layer, exposed to the weather. It protects the other roofing components, including insulation, from exposure to water, wind and other weather conditions. Conventionally Insulated Waterproofing System are classified in this Manual by three different methods of attachment (securement) to the roof deck:

- Mechanically Attached Roof Systems (MARS)

- Partially Adhered Roof Systems (PARS)

- Adhesive Applied Roof Systems (AARS)

More about these three systems is offered in Part 3 SECURING the ROOF ASSEMBLY.

3.2.2 Protected and Modified Protected Membrane Roof Systems

NOTE: See more information on Protected and Modified Protected Roof Systems in Division B: Essential Elements.

- In a Protected Membrane Roof System (or Protected Membrane Roof Assembly, also called PMRA) the membrane is applied directly to the supporting deck structure or the deck overlay (as required and/or specified), and protected from both the elements and damage with insulation and an overburden. In this way, the membrane functions both to waterproof the roof and control air or vapour. Only RoofStar-accepted extruded expanded polystyrene (XPS, conforming to CAN / CGSB-51.20-M87, Type 4) is acceptable for a PMRA. XPS is water-resistant (i.e. resistance to water absorption, moisture transfer, and capillary action), freeze-thaw cycling resistant, and possesses a high compressive strength. If a drainage layer is specified, it is typically installed between the membrane and insulation. An additional drainage layer may be installed above the insulation, together with a filter fabric mat and ballast or overburden. These three components - a drainage layer, filter fabric and ballast - promote controlled drainage, resist infiltration of contaminants, resist the lifting forces of wind, and counteract the natural buoyancy of the insulation.

- PMRAs are the required roof assembly design for certain types of overburden. See 14.1.2 Design for RoofStar Guarantee Standards.

- A Modified Protected Membrane Roof System (or Modified Protected Membrane Roof Assembly, also called MPMRA) is similar to a PMRA except that that insulation is installed both below and above the membrane. This may offer cost savings as only the top layer of insulation requires ballast and the bottom layer (mechanically fastened or adhered) need not be extruded expanded polystyrene and may be tapered to provide slope. As a general rule, two-thirds or more of the total thermal resistance (RSI or R value) should be above the membrane, but in all cases the Design Authority should perform the required psychrometric calculations before designing a roof system.

3.3 Accessibility for Maintenance

3.3.1 RoofStar 15-Year Guarantee

- On all "new construction" Projects, where external access is not provided, all roofs with a field elevation greater than 7500 mm (25’) above grade must incorporate safe, appropriate access to the roof, for example by incorporating stairs and a doorway or a properly located roof hatch. These requirements are recommended for existing buildings to facilitate maintenance and ongoing performance reviews.

3.3.2 All Projects

While the RoofStar Guarantee Standards pertain to the design and construction of a leak-free roof, accessible design is still critical since a roof must be regularly maintained. Therefore, while the following list is not exhaustive, the Design Authority is urged to consider these guiding principles when designing a roof Project.

- All roofs with a field elevation greater than 7500 mm (25’) above grade should incorporate access to the roof by stairs and a doorway or with a properly located roof hatch.

- Any hatch, ladder or mechanical unit should be located a sufficient distance away from the roof edge (setback zone) so that other fall protection measures are not required by those using or accessing this equipment. When it is not possible to situate a hatch, ladder or mechanical unit outside the setback zone, guard rails should be designed for the roof edge to provide additional fall protection for those using or accessing such equipment.

- Each roof should be designed to provide safe access for maintenance of roof drains, corners or mechanical equipment, where the roof is at least 3 m (10’) above the surface of the ground, or where a hazard to a person exists, should a fall be possible. This principle also applies to roof areas intended for regular occupancy. Therefore, provide fall protection in compliance with the Code having jurisdiction, and with the Workers Compensation Act Regulations, by designing appropriately located

- tall parapets.

- guardrails.

- tie-off anchors.

3.4 Waterproofing Integrity Scans and Electronic Leak Detection

An integrity scan is performed after the installation of the roof waterproofing system, before any overburden, equipment or amenity space is installed on top of it. An integrity scan typically uses low-voltage electrical current to detect even the smallest breaches in the roof membrane, but some waterproofing materials may require the use of other technologies to verify the roof system’s integrity. Therefore, Design Authority should specify the appropriate technology, keeping in mind the limitations of each scan and detection methodology, and of the membranes that are specified.

Electronic Leak Detection (ELD) utilizes low-voltage electrical current, typically conducted through wires installed in a grid pattern. ELD technologies are used in response to a leak, to isolate its location in order to minimize investigation time and material removal. This can benefit a building owner who will have to bear the costs of demolition or overburden removal when the standard limits of coverage afforded by the RoofStar Guarantee are exceeded by the Project design and construction. ELD technologies may be passive (installed but not monitored) or actively monitored (by the installer, through real-time data collection).

- Flood testing (as an alternative to an integrity scan) is not recommended. When flood testing is specified, testing shall be conducted prior to installation of insulation and roof coverings, and must be performed following the methodologies in ASTM D5957.

- Neither an integrity scan nor an Electronic Leak Detection (ELD) system are considered Accepted Materials, but firms that provide these services are nevertheless specifically recognized and approved by the RoofStar Guarantee Program.

- An integrity scan is required for some projects (see 1.6 RoofStar Guarantee: Coverage and Limitations), but is nevertheless strongly recommended before the completed roof assembly is covered with overburden, equipment or living (amenity) spaces (see 14.1.2.1).

- Electronic Leak Detection is required for all grade-level waterproofing systems, and while it is optional for roof waterproofing systems, ELD is strongly recommended

- for projects where multiple trades will have access to a roof that is under construction and completed, in order to identify breaches in the waterproofing membrane in a timely way and avoid future costly delays.

- when the roof assembly protects a sensitive occupied space (i.e. data centres, hospitals, critical infrastructure).

- when the roof supports any type of overburden, equipment or living (amenity) space.

- When Electronic Leak Detection is specified, it should provide detection capabilities for all waterproofed surfaces, and should extend at least 50 mm (2") vertically from the water plane at

- all transitions.

- any point along the entire deck perimeter.

- protrusions.

3.5 Hot Works: Design

When any portion of a waterproofing system is installed with heat, the work is classified as Hot Works. Some tools used in the course of Hot Works can ignite combustible materials, and some building environments are more sensitive to fire than others, such as a building containing, or close to, flammable liquids. Hot Works may occur during

- tear off (sparks).

- deck preparation (drying wet surfaces).

- cold temperatures (warming materials or surfaces).

- equipment use (sparks within electrical tools, or from cutting, drilling or grinding metal, concrete, stone or other hard surface products).

- The Design Authority may specify that the Contractor must maintain compliance with the RCABC Hot Works Program and consequently manage the Hot Works conducted on site.

- When the Project involves Hot Works, the Design Authority must either

- pre-approve alternate applications already written within the Manual when the specified application is deemed to be fire-sensitive by the Contractor as part of the risk assessment process.

- provide alternate material and application requirements in the specification for fire-sensitive locations on the project.

See also 1.4.3 Hot Works

- Contractor Requirements.

3.6 Variances

When a design is unable to conform to the Standard, the Design Authority may apply to the RGC for a written Variance. Application must be made in writing (email correspondence is common), and the request must

- identify the project name, its civic address and the applicable RoofStar Guarantee number (if already initiated).

- articulate the nature of the design problem.

- cite the RoofStar Guarantee standard reference to which the Variance will apply.

- provide design drawings (and photographs, if available) as supporting information.

We may ask for more information in order to fully consider a request for a Variance and will issue a completed Variance only to the Design Authority for distribution to the Contractor.

A Variance may be unrestricted in its scope, or it may include one or more conditions that will affect the design and construction of the water-shedding system or waterproofing system, in order to accommodate the varied standard. Occasionally, a Variance may also restrict coverage offered by the RoofStar Guarantee.

Variances are issued only for the specific issue on the project identified in the written request, and do not constitute general permission to depart from the published requirements in this Standard, for any aspect of the same project or for future projects, designed or constructed by any other firm.

4 Scope

- The Guarantee Standards, Guiding Principles, Recommendations and Reference Materials in this Standard pertain to both new roofing construction and replacement roofing, unless explicitly stated otherwise.

4.1 New Construction

- New roof construction must utilize only newly manufactured materials, and may not incorporate recycled products, unless with the expressed, written consent of the Guarantor.

4.2 Replacement Roofing and Additions

As a roof ages, is neglected or is damaged, it may lose its ability to perform reliably and effectively, necessitating replacement. Replacement roofing, also referred to as "re-roofing," whether made in whole or in part, should be undertaken with the Quality Assurance and Quality Control provided for under the RoofStar Guarantee Program. Regardless of the approach to replacement roofing, the existing deck structure must meet the pullout resistance rating for mechanical fasteners and must be capable of supporting all dead and live loads. Furthermore, the deck must be capable of supporting any additional dead loads of the new roof system.

Three types of replacement roofing are contemplated and permitted (with varying degrees of limitations and conditions) under the RoofStar Guarantee Program:

- System replacement - removal and replacement of all roof system components, except for the supporting deck structure.

- Membrane replacement – removal and replacement of the roof membrane, while retaining existing roof system components (i.e. insulation, ballast).

- Recovering - installation of a new membrane over an existing membrane, while retaining some or all of the other roof system materials (NOTE: Recovering is permitted only with a written Variance issued by the Guarantor).

Qualifying and construction conditions and limitations for each of these replacement options are described below. Other conditions and limitation may be determined by the Guarantor subject to the nature and specifications of the replacement roofing project.

4.2.1 System Replacement