Difference between revisions of "Materials:(Bothwell-Accurate) BA-Versaspan 200 (SS 200)"

Difference between revisions of "Materials:(Bothwell-Accurate) BA-Versaspan 200 (SS 200)"

(→SYSTEM DESCRIPTION) |

(→SITE CONDITIONS) |

||

| Line 47: | Line 47: | ||

====SITE CONDITIONS==== | ====SITE CONDITIONS==== | ||

| − | + | Fabricated panels (on site if necessary) in one continuous length to suit site requirments. This 2" tall seam height panel is highly recommend for use on slopes less than 3"/12" | |

====PERFORMANCE REQUIREMENTS==== | ====PERFORMANCE REQUIREMENTS==== | ||

Revision as of 18:44, 29 June 2021

| The metal panel listed and described below is accepted for use in the RoofStar Guarantee Program. |

The roofing assembly / material information published below and in the RCABC Roofing Practices Manual DOES NOT represent a complete set of the manufacturer's published data, nor does it represent a detailed specification. The preparation of a detailed specification is the responsibility of the design authority. For more information about this product or system, consult the manufacturer. |

OVERVIEW

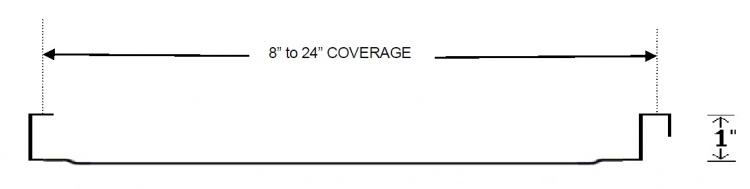

The SS 200 (BA-Versaspan 200) standing seam panel is formed with an on-site / in-shop continuous metal roofing panel roll forming machine NTM-SSQ. This machine produces a standing seam panel with a seam height of 50.8mm (2") and profiles can vary from 305mm (12") wide up to 508mm (18") wide. This machine also produces BA-Versaspan1 (SS100), BA-Versaspan1.5 (SS150), BA-Versaclip (SS675), and BA-Versasnap (FF100).

On-site roll forming provides for the elimination of end laps with continuous panel forming capabilities in lenghts up to 200' plus.

SYSTEM DESCRIPTION

- General: The BA-Versaspan2 (SS200) is a concealed fastener standing seam roof panel. The panel is attached with clips to allow for expansion and contraction.

- Range of application: Installed on wood or steel sloped roofs in commercial, instititutional, industural, and residential construction. Ideal for low slope applications because of the 2" (50.8mm) tall seam height.

- Fasteners (Screws): Fasteners are fixed through clips that hook onto the male leg of the panel. Minimum two fasteners per clip to be used. Spacing is site specific, engineer must confirm fastening specifications.

- Roof Deck Fasteners (Panel Clips): One piece assembly 43.75 mm (1-3/4") wide, 31 mm (1-1/4") high. Minimum thickness 0.022 in. (No. 22 MSG). Clips spaced maximum 900 mm (36") O.C., fastened to plywood deck.

- Deck Requirements: in keeping with the Standard for Architectural Sheet Metal (ASM) Systems.

PROFILE

| BA-Versaspan 1 (SS 100) Standing Seam Panel |

|---|

|

TECHNICAL DATA SHEET

Click below for the Technical Data Sheet

SITE CONDITIONS

Fabricated panels (on site if necessary) in one continuous length to suit site requirments. This 2" tall seam height panel is highly recommend for use on slopes less than 3"/12"

PERFORMANCE REQUIREMENTS

- Wind Uplift Standards: Engineered designs to resist wind uplift may refer to the British Columbia Building Code, Div. B, Appendix C, Table C-2 which lists various types of loads, including wind loads, for specific reference locations throughout the province. See also Guides and Notes (Wind Resistance) for a simplified calculation procedure. Regardless of the resources indicated here, the Design Authority is responsible to perform accurate wind load calculations and specify securement requirements.

- Materials:RoofStar (RGC) accepted metal panel systems shall be formed of steel conforming to the standards published in the Standard for Architectural Sheet Metal (ASM) Systems.