Difference between revisions of "Securing the Roof Assembly"

Difference between revisions of "Securing the Roof Assembly"

(→3.1.3.2. Calculation of Specified Wind Loads) |

|||

| (18 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | {{Template:RPM Info}} | ||

| + | |||

| + | __NONUMBEREDHEADINGS__ | ||

| + | <div class="row"> | ||

| + | |||

| + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | ||

<div class="row"> | <div class="row"> | ||

<div class="col-md-3" style="float:right;" id="tocDiv"> | <div class="col-md-3" style="float:right;" id="tocDiv"> | ||

| − | __TOC__ | + | <div class="noautonum">__TOC__</div> |

</div> <!-- tocDiv --> | </div> <!-- tocDiv --> | ||

<div class="col-md-9" id="mainBodyDiv"> | <div class="col-md-9" id="mainBodyDiv"> | ||

| + | |||

| + | <big><big>Wind Uplift Resource Centre</big></big><br> | ||

| + | |||

| + | <hr> | ||

| + | <big><big><big><big><big><big>Securing the Roof Assembly</big></big></big></big></big></big> | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | | style="background-color: #ffffcc;" | | ||

| + | The following content is replicated from Part 3 of the ''Standard for SBS-modified Bitumen Membrane Roof Systems'', located in [[Division B | '''Division B: Standards''']], and is largely identical to Part 3 found in any of the other membrane Standards available in this ''Manual''. As a Part of an entire Standard, it must be read together with all the other Parts. | ||

| + | |- | ||

| + | |} | ||

<div style="width:150px; text-align: left;"> | <div style="width:150px; text-align: left;"> | ||

| Line 11: | Line 29: | ||

</div> | </div> | ||

<div style="text-align: left;"> | <div style="text-align: left;"> | ||

| − | Click on the gif above to see the '''full high-definition video''', which illustrates why roof system | + | Click on the gif above to see the '''full high-definition video''', which illustrates why ''roof system'' securement requirements matter ('''NOTE''': the video shows a mechanically fastened, conventionally insulated EPDM ''roof system'' constructed to the '''''RoofStar Guarantee''''' Standard of the time (2013). The membrane "flutter" in wind is common for this type of ''roof system''). |

</div> | </div> | ||

| − | ==General== | + | ==Section 3.1. Design== |

| − | === | + | ===3.1.1. General=== |

| − | + | ====3.1.1.1. Scope==== | |

| + | (See [[Notes to SBS Standard#A-3.1.1.1.| Note A-3.1.1.1.]]) | ||

| + | |||

| + | <ol> | ||

| + | <li>The scope of this Part and the Standard shall be as described in [[Scope of RPM and Standards | Division A, Part 1]]. | ||

| + | <li>{{hilite |This Part applies to all new roofs, and to both full and partial replacement ''roof systems''|| 2021-October-30 }}. | ||

| + | <li>{{hilite |This Part sets out the requirements for|| 2021-October-30 }} | ||

| + | <ol> | ||

| + | <li>material substitution (applicable to ''Tested Assemblies''), | ||

| + | <li>fastener and adhesive application (minimum numbers and spacing), | ||

| + | <li>roofs that support ''overburden'', or fixed amenities and equipment, and | ||

| + | <li>roofs where only part of the ''system'' must be replaced. | ||

| + | </li></ol> | ||

| + | <li>{{hilite |''Conventionally insulated roof systems'' designed and constructed with sheet membranes must be secured using|| 2021-October-30 }} | ||

| + | <ol> | ||

| + | <li>{{hilite |a ''Tested Assembly'' (a membrane ''roof system'', together with a specified roof ''deck'', tested for its wind resistance capabilities using CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition)|| 2021-October-30 }}(See [[Notes to SBS Standard#A-3.1.1.1.(4)| Note A-3.1.1.1.(4)]]), or | ||

| + | <li>{{hilite |an ''Assembly with Proven Past Performance'' (an existing, representative ''roof system'', together with a specified roof ''deck'', which is used as a “proven” pattern for securing a new ''roof system'' on the building under consideration; see [[#3.1.4.3. Specifying an Assembly with Proven Past Performance | Article 3.1.4.3.]])|| 2021-October-30 }}. | ||

| + | </li></ol> | ||

| + | <li>{{hilite |When neither of the foregoing options is available to the ''Design Authority'' to conform to the Code, the ''roof system'' must be secured using a custom engineered design (See [[#3.1.4.4. Specifying a Custom-engineered Securement Design | Article 3.1.4.4.]])|| 2021-October-30 }}. | ||

| + | </li></ol> | ||

| + | |||

| + | ===={{hilite | 3.1.1.2. Intent || 2021-October-30 }}==== | ||

| + | (See [[Notes to SBS Standard#A-3.1.1.2. | Note A-3.1.1.2.]]) | ||

| − | + | <ol> | |

| − | + | <li>The requirements in this Part intend to support and conform to or exceed the Building Code. | |

| − | + | </li></ol> | |

| − | === | + | ===={{hilite | 3.1.1.3. Limit of Liability under RoofStar Guarantee || 2021-October-30 }}==== |

| − | |||

| − | + | <ol> | |

| − | + | <li>{{hilite |Notwithstanding [[#3.1.1.2. Intent | Article 3.1.1.2.]], the materials presented herein are based on an interpretation of the Code and are not the Code itself; therefore, the reader is responsible to exercise good judgement, and to read, understand and comply with the Code, as and how it applies to the reader’s particular ''project'' and its design requirements. | |

| − | + | <li>Where the Code can be shown to exceed the requirements, guiding principles, and recommendations of this Part or any related Part in this Standard, the Code shall prevail|| 2021-October-30 }}. | |

| − | + | <li>{{hilite |Compliance with this Part or the Code does not guarantee that a roof will not succumb to forces exerted by wind, and therefore neither the '''''Guarantor''''' nor the ''Contractor'' will accept any responsibility for damage to, or failure of, a roof system caused by wind; too many variables beyond the control of this Standard affect the wind resistance performance of a ''roof system'', including (without limitation)|| 2021-October-30 }} | |

| + | <ol> | ||

| + | <li>{{hilite | the continuity or discontinuity of air and vapour control layers of the entire building enclosure|| 2021-October-30 }}, | ||

| + | <li>{{hilite | openings in the building (windows and doors, which are often occupant-controlled and not static)|| 2021-October-30 }}, and | ||

| + | <li>{{hilite | wind strength, which may exceed the codified numeric wind speed values used to calculate wind resistance for the roof system (Ref. "British Columbia Building Code", Division B, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbacr2 Appendix C, "Table C-1"])|| 2021-October-30 }}. | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| − | + | ====3.1.1.4. Definitions==== | |

| − | |||

<ol> | <ol> | ||

| − | <li> | + | <li>Words that appear in italics are defined in the [[Glossary | Glossary]]. Additionally, the following terms are used in this Part: |

| − | <li> | + | <ol> |

| + | <li>''CSA Standard'' means the CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition). | ||

| + | <li>''Registered Professional'' has the same meaning as that used in the "British Columbia Building Code", Division C, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dcp2s22r2 Section 2.2., "Administration"]. | ||

| + | <li>''Specified Wind Load'' means the calculated force of wind exerted on the roof of a specific building, according to the requirements in the "British Columbia Building Code", Division B, Part 4, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbp4s41r2 Section 4.1., "Structural Loads and Procedures"]. | ||

| + | <li>{{hilite | ''System of securement'' means a specific pattern of mechanical fasteners or adhesives, including specific materials or brands, size, and spacing. || 2023-June-16 }} | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.1.2. Guarantee Term Requirements=== | ||

| + | ====3.1.2.1. RoofStar 5-year and RoofStar 10-year Guarantee==== | ||

| + | |||

<ol> | <ol> | ||

| − | <li>''' | + | <li>To qualify for a '''''RoofStar 5-year''''' or '''''RoofStar 10-year Guarantee''''', all ''projects'' shall comply with the requirements in this Part. |

| − | <li>''' | + | </li></ol> |

| − | <li>''' | + | |

| − | + | ====3.1.2.2. RoofStar 15-Year Guarantee==== | |

| − | + | ||

| − | + | <ol> | |

| − | + | <li>To qualify for a '''''RoofStar 15-year Guarantee''''', all ''projects'' shall comply with the requirements in this Part for a '''''RoofStar 5-year''''' or '''''RoofStar 10-year Guarantee''''', and shall | |

| − | + | <ol> | |

| + | <li>{{hilite |comply with the higher securement requirements when enhanced ''roof system'' securement is required by the membrane manufacturer, to meet their system warranty requirements ("enhanced securement" may exceed the securement stated or specified in a ''Tested Assembly'', an ''Assembly with Proven Past Performance'', or a custom-engineered design; see also [[#1.1.2.1. RoofStar 5-Year and RoofStar 10-year Guarantee | Article 1.1.2.1., ''RoofStar 15-Year Guarantee'']], for further general requirements|| 2020-October-22 }}). | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.1.3. All Systems=== | ||

| + | ====3.1.3.1. Responsibility for Design==== | ||

| + | |||

| + | <ol> | ||

| + | <li>The ''Design Authority'' is responsible for determining ''Specified Wind Loads'' for each ''roof system'' and each roof area of a ''project'', including roofs that support ''Vegetated Roof Systems'' or any other ''overburden'', amenities, or equipment. | ||

| + | <li>Acceptance of a roof for a '''''RoofStar Guarantee''''' is predicated on the assumption that the ''Design Authority'' has performed Due Diligence with respect to ''Specified Wind Loads'' and has provided the ''Contractor'' with sufficient information to construct a ''roof system'' that complies with the Code. | ||

</li></ol> | </li></ol> | ||

| − | <li>A | + | |

| + | ====3.1.3.2. Calculation of Specified Wind Loads==== | ||

| + | |||

| + | <ol> | ||

| + | <li>A ''registered professional'' "skilled in the work concerned" must perform or validate the calculation of ''Specified Wind Loads'' (See the "British Columbia Building Code", Division C, Part 2, Section 2.2., "Administration": [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dcp2s22r2 Article 2.2.2.2., ''Structural Design'']), using | ||

<ol> | <ol> | ||

| − | <li> | + | <li>the [https://nrc.canada.ca/en/research-development/products-services/software-applications/wind-load-calculators-roof-cladding-vegetated-roof-assembly "Wind Uplift Resistance Calculator"] (formerly "Wind-RCI"), or |

| − | + | <li>the formulae and procedures in the "British Columbia Building Code", Division B, Part 4, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbp4s41r2 Subsection 4.1.7.,"Wind Load"] (See [[Notes to SBS Standard#A-3.1.1.1. | Note A-3.1.1.1.]]). | |

| − | <li> | + | </li></ol> |

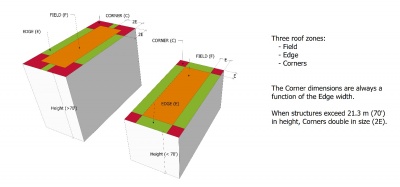

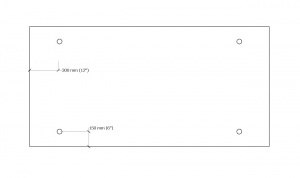

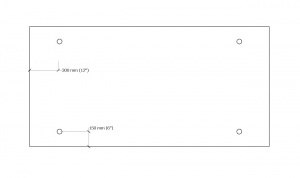

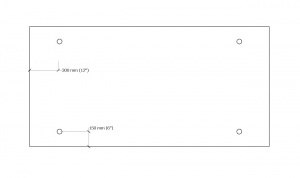

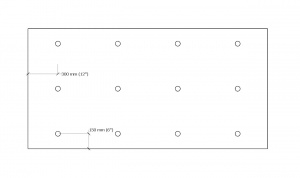

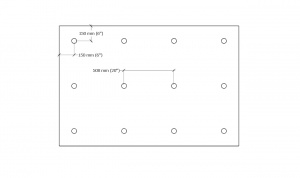

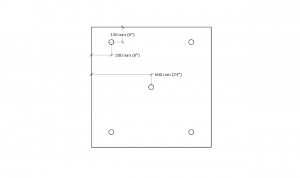

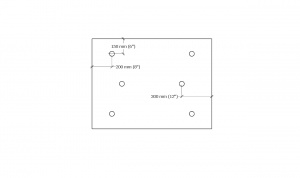

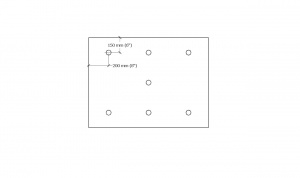

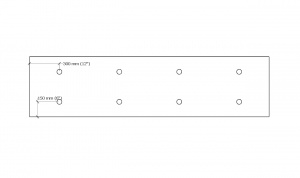

| − | <li> | + | <li>Each roof area, at each level (elevation), shall be divided into three principal roof zones (Figure 3.1.), and the ''Design Authority'' shall be responsible for calculating the ''Specified Wind Loads'' for each zone (Ref. the "British Columbia Building Code", Division B, Part 4, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbp4s41r2 Article 4.1.7.6., "External Pressure Coefficients for Low Buildings"]). |

| − | + | <li>Roof zones are defined in this Standard as follows: | |

| − | <li> | ||

<ol> | <ol> | ||

| − | <li>the '' | + | <li>'''Field (F)''' – the interior of the roof bounded by the ''Edge'' and the ''Corners''. |

| − | <li> | + | <li>'''Edge (E)''' – the perimeter zone (minus the corners), measured as either 10% of the smallest building width ("least horizontal dimension"), or 40% of the building height, whichever is less. Notwithstanding the requirements in the "British Columbia Building Code", the ''Edge'' zone shall not be less than 2.0 m (7'). |

| − | {| class="wikitable" | + | <li>'''Corner (C)''' – part of the perimeter but not less than 2.0 m x 2.0 m (7’ x7’) in size, the ''Corner'' area is defined by the ''Edge'' in both directions at the corners. Where the roof geometry includes an inside corner, the ''corner'' zone dimensions shall be the same as those for an outside corner, applied equidistant in each direction from the inside corner (Figure 3.1.3.-A). |

| − | |+Figure 3. | + | </li></ol> |

| + | {| class="wikitable"; table style="background-color:white"; border="#A9A9A9;" | ||

| + | |+ <small>Figure 3.1.3.-A (Click to expand)</small> | ||

|- | |- | ||

| − | | | + | | [[File:Figure 3.1.jpg|link=http://rpm.rcabc.org/images/1/11/Figure_3.1.jpg | 400 px]] |

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<br> | <br> | ||

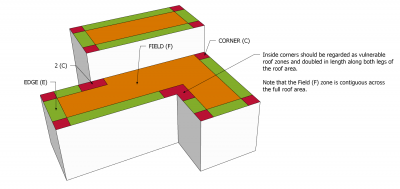

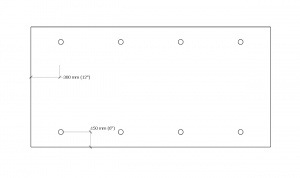

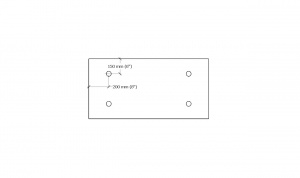

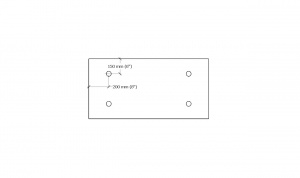

| − | + | <li>A roof area that is divided into smaller segments by means of ''control joints'' (roof dividers, i.e., a fire wall) or ''expansion joints'', shall be considered one roof area for the purpose of calculating the ''Specified Wind Loads'', unless the height of a ''control joint'' or ''expansion joint'' exceeds 1 m (39"), in which case the ''Specified Wind Loads'' for each roof segment shall be calculated separately (See Figure 3.1.3.-B). | |

| − | <li | + | <li>When a building is designed with multiple roof levels (at different elevations), and the roofs are adjacent each other (having a common wall), the ''Specified Wind Loads'' for each level, and for each roof area on that level, shall be calculated separately from loads for the adjacent level, unless the elevation difference between adjacent roof levels is less than 1.524 m (5’) (Ref. Figure 3.1.3.-B). |

| − | + | <li>When the shape of a single-level roof varies in width or length, the smallest width dimensions shall be used in the calculation of ''Specified Wind Loads'' (Ref. “minimum effective width” as defined in the "British Columbia Building Code", Division B, Part 4, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbp4s41r2 Article 4.1.7.2., "Classification of Buildings"]). | |

| − | <li> | + | {| class="wikitable"; table style="background-color:white"; border="#A9A9A9;" |

| − | {| class="wikitable" | + | |+ <small>Figure 3.1.3.-B (Click to expand)</small> |

| − | |+Figure 3.3 | ||

|- | |- | ||

| − | | [[File:Figure 3.3. | + | | [[File:Figure 3.1.3.-B.png|link=https://rpm.rcabc.org/images/d/da/Figure_3.1.3.-B.png | 400 px]] |

|} | |} | ||

| − | </li> | + | <br> |

| − | </ol> | + | <li>When a roof area intersects the corner of a wall, the ''Edge'' zone on either side of the wall corner must be treated as a roof ''Corner'' (2 x C) (Figure 3.1.3.-B). |

| + | <li>When an existing roof system is specified for partial replacement, the ''Design Authority'' must | ||

| + | <ol> | ||

| + | <li>calculate the ''Specified Wind Loads'' for the roof, | ||

| + | <li>determine if securement of the remaining roof components (left in situ) is sufficient to resist the ''Specified Wind Loads'', | ||

| + | <li>determine a suitable method of securement or have the ''system'' of securement engineered, and | ||

| + | <li>calculate and design securement for any ''overburden'', amenities, or equipment. | ||

| + | </ol></li> | ||

| + | <li><span class="principles">''Roof systems'' should be designed in conjunction with the electrical systems for the building, to avoid unnecessary interference with ''roof system'' securement</span> (See also [[#2.1.8. Electrical Cables and Boxes | Subsection 2.1.8., "Electrical Cables and Boxes"]]). | ||

| + | <li>Mansards are a ''roof system'' and are therefore subject to the requirements in this Part. | ||

| + | <li>Securement of an adjoining ''water-shedding system'' shall be made in accordance with the requirements in the applicable Standard. | ||

| + | <li>''Vegetated Roof Systems'' specified for | ||

| + | <ol> | ||

| + | <li>buildings up to 20 m (65') in height shall be designed to resist ''Specified Wind Loads'' using the [https://nrc.canada.ca/en/research-development/products-services/software-applications/wind-load-calculators-roof-cladding-vegetated-roof-assembly "Wind Load Calculator for Vegetated Roof Assembly"] or, in the alternative, another method that is its equal or superior, and | ||

| + | <li>buildings greater than 20 m (65') in height shall be designed to resist '' Specified Wind Loads'' using methods that are acceptable to the ''Authority Having Jurisdiction'' (AHJ). | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| − | ==== | + | ====3.1.3.3. Resistance to Specified Wind Loads==== |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <ol> | |

| − | + | <li>The wind uplift resistance capabilities of the selected ''roof system'' must equal or exceed the ''Specified Wind Loads'' calculated for each roof zone to which the ''system'' will be applied (see [[#3.1.3.2. Calculation of Specified Wind Loads | Article 3.1.3.2.]]). | |

| − | + | <li>Engineered designs to resist wind uplift may refer to the "British Columbia Building Code", Div. B, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbacr2 Appendix C, "Table C-2"], which lists various types of loads, including wind loads, for specific reference locations throughout the province. | |

| + | </li></ol> | ||

| − | === | + | ====3.1.3.4. Resistance to Other Loads==== |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<ol> | <ol> | ||

| − | <li> | + | <li>In addition to its capacity to resist ''Specified Wind Loads'', the ''roof system'' must be capable of resisting or accommodating |

| − | <li>< | + | <ol> |

| + | <li>all anticipated live and dead loads, including (without limitation) other environmental loads, such as rain and snow, expected for the building’s size and location, | ||

| + | <li>gravity ("drag") loads, | ||

| + | <li>{{hilite | loads from ''overburden'' || 2023-June-16 }} (See [[#Part 14 - The Roof as a Platform | Part 14]]), and | ||

| + | <li>thermal expansion and contraction of the ''roof system'' components. | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | ====3.1.3.5. Submittals==== | ||

| + | |||

| + | <ol> | ||

| + | <li>The ''Design Authority'' must submit documentation in support of a "System with Proven Past Performance", as required in [[#3.1.4.3. Specifying an Assembly with Proven Past Performance | Article 3.1.4.3.]] | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.1.4. Conventionally Insulated Roof Systems=== | ||

| + | (The requirements in [[#3.1.3. All Systems | Subsection 3.1.3., "All Systems"]], shall be read together with the following articles) | ||

| + | |||

| + | ====3.1.4.1. Securement Against Specified Wind Loads==== | ||

| + | (See [[Notes to SBS Standard#A-3.1.4.1.| Note A-3.1.4.1.]]) | ||

| + | |||

| + | <ol> | ||

| + | <li>New and fully replaced ''conventionally insulated systems'' shall satisfy the requirements of the "British Columbia Building Code" and this Part, and shall be (when applicable) | ||

| + | <ol> | ||

| + | <li>an Adhesive Applied Roof System ("AARS"), | ||

| + | <li>a Partially Adhered Roof System ("PARS"), or | ||

| + | <li>a Mechanically Attached Roof System ("MARS"), | ||

| + | </li></ol> | ||

| + | which may be specified as | ||

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite | a ''Tested Assembly''|| 2020-July-3 }}, |

| − | + | <li>{{hilite | an ''Assembly with Proven Past Performance''|| 2020-July-3 }}, or | |

| − | + | <li>{{hilite | an ''assembly'' with custom-engineered securement|| 2020-July-3 }}. | |

| − | + | </li></ol> | |

| − | + | </li></ol> | |

| − | + | ||

| − | + | ====3.1.4.2. Specifying a Tested Assembly==== | |

| − | + | (See [[Notes to SBS Standard#A-3.1.4.2.| Note A-3.1.4.2.]]) | |

| − | | | ||

| − | | | ||

| − | |- | ||

| − | |||

| − | |- | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | <li> | ||

| − | |||

| − | |||

| − | |||

| − | + | <ol> | |

| − | (''' | + | <li>Only roof assemblies that have been tested by qualified facilities wholly independent of ''roof system'' manufacturers, using CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition), will be considered valid ''Tested Assemblies'', for the purposes of this Standard (See [http://rpm.rcabc.org/index.php/CSA_A123.21_Qualified_Test_Facilities '''here'''] for a list of qualified testing agencies). |

| + | <li><span class="recommended">The ''Design Authority'' is strongly encouraged to specify the application of a ''Tested Assembly'', for any design of a new or fully replaced membrane waterproofing ''roof system''</span>. | ||

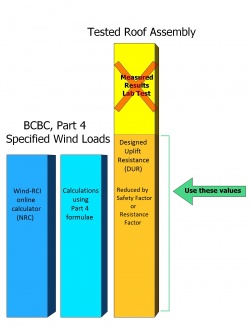

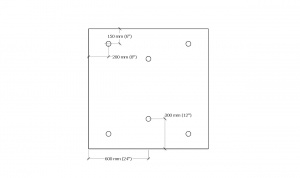

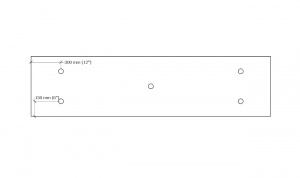

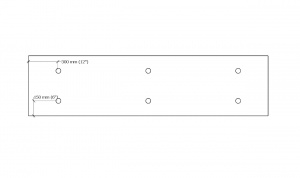

| + | <li>The ''Design Authority'' must use only the test observation readings that have been adjusted for the "Safety Factor" (CSA-A123.21, prior to the 2019 edition) or the "Resistance Factor" (CSA-A123.21, 2019 and newer), which must equal or exceed the highest ''Specified Wind Loads'' for the roof (this adjusted value is called the ''Dynamic Uplift Resistance'', or DUR. See Figure 3.1.4.-A). | ||

| + | <li>When a ''Tested Assembly'' report indicates only one system of securement, that system shall be applied to all roof zones; alternatively, zone-specific securement requirements may be extrapolated by a ''Registered Professional'' "skilled in the work concerned", using ANSI-SPRI WD-1, "Wind Design Standard Practice for Roofing Assemblies" (see the "British Columbia Building Code", Division B, Part 5, Notes to Part 5, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbp5n "A-5.2.2.2.(4)"]). | ||

| − | + | {| class="wikitable"; table style="background-color:white"; border="#A9A9A9;" | |

| − | + | |+{{hilite | <small>Figure 3.1.4.-A (Click to expand)</small> || 2020-July-3 }} | |

|- | |- | ||

| − | | | + | | [[File:Figure 3.4.jpg|link=http://rpm.rcabc.org/images/d/d8/Figure_3.4.jpg | 250 px]] |

| − | |||

| − | |||

|} | |} | ||

| + | </li></ol> | ||

| − | + | ====3.1.4.3. Specifying an Assembly with Proven Past Performance==== | |

| − | + | (See the "British Columbia Building Code", Division B, Part 5, Notes to Part 5, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbp5n "A-5.1.4.1.(5)"] for an expanded explanation of the tests for "proven past performance") | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | + | <ol> |

| + | <li>A new ''conventionally insulated'' ''roof assembly'' (the ''new roof assembly'') may be designed using a ''model roof assembly'' as a reference (the roof ''Assembly with Proven Past Performance''), but only when | ||

| + | <ol> | ||

| + | <li>a ''Tested Assembly'' cannot be used, | ||

| + | <li>the material components identified in a ''Tested Assembly'' are not accepted by the '''''RoofStar Guarantee Program''''', and the test report offers no RoofStar-accepted alternates, | ||

| + | <li>a ''Tested Assembly'' is not available because a material or ''system'' has not been tested, or because the ''Specified Wind Loads'' exceed the capacity of an available or suitable ''Tested Assembly'', | ||

| + | <li>the ''model roof assembly'' | ||

| + | <ol> | ||

| + | <li>is an existing ''roof assembly'' constructed on a real, existing building (the ''model building''), | ||

| + | <li>demonstrates resistance to negative wind loads that are the same as, or greater than, the ''Specified Wind Loads'' which the ''new roof assembly'' must be designed to resist, | ||

| + | <li>has a history of performance equal to or longer than the expected service life of the ''new roof assembly'', and | ||

| + | <li>is designed with only RoofStar-accepted materials that possess properties "identical or superior to those of the...assembly used as a reference" (Ref. the "British Columbia Building Code", Division B, Part 5, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dbp5n "Notes to Part 5"]), | ||

| + | </li></ol> | ||

| + | <li>the ''model building'' | ||

| + | <ol> | ||

| + | <li>is similar in dimensions, exposure, openings, and importance to the building that will support the ''new roof assembly'', and | ||

| + | <li>is situated in conditions representative of the building that will support the ''new roof assembly'' (the term "representative" refers to conditions that include, without limitation, dynamic loads caused by proximity to other structures because of funneling or building harmonics). | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | <li>To qualify for a '''''RoofStar Guarantee''''', a ''new roof assembly'' patterned after an ''Assembly with Proven Past Performance'' must be supported with a letter of assurance provided to the '''''Guarantor''''' by the ''Design Authority'', or by the manufacturer of the ''Assembly with Proven Past Performance'', signed by the Principal or a person having the authority of the Principal, stating that the ''new roof assembly'' will resist the ''Specified Wind Loads'' calculated for the ''new roof assembly''. | ||

| + | <li>A ''new roof assembly'' patterned after an ''Assembly with Proven Past Performance'' may be used for partial roof replacement. | ||

| + | <li>Published approvals issued by an insurer or underwriter, or roof assembly designs warranted or guaranteed by anyone other than the '''''Guarantor''''', do not satisfy the requirements for a roof ''Assembly with Proven Past Performance''. | ||

| + | </li></ol> | ||

| + | ====3.1.4.4. Specifying a Custom-engineered Securement Design==== | ||

| − | < | + | <ol> |

| + | <li>When, for various reasons, a system of securement cannot be designed using either a ''Tested Assembly'' or an ''Assembly with Proven Past Performance'', the securement system must be designed by a ''Registered Professional'' "skilled in the work concerned" (See the "British Columbia Building Code", Division C, Part 2, [http://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dcp2s22r2 Article 2.2.1.2., "Structural Design"]). | ||

| + | </li></ol> | ||

| − | The | + | ===3.1.5. Uninsulated Systems=== |

| + | (The requirements in [[#3.1.3. All Systems | Subsection 3.1.3., "All Systems"]], shall be read together with the following articles) | ||

| − | ==== | + | ====3.1.5.1. Securement against Specified Wind Loads==== |

| − | + | <ol> | |

| − | + | <li>All uninsulated ''roof systems'' must be designed to resist displacement by ''Specified Wind Loads'', using the options articulated in [[#3.1.4.1. Securement Against Specified Wind Loads | Article 3.1.4.1.]] | |

| − | + | </li></ol> | |

| − | |||

| − | === | + | ===3.1.6. Protected Roof Systems=== |

| − | + | (The requirements in [[#3.1.3. All Systems | Subsection 3.1.3., "All Systems"]], shall be read together with the following articles) | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ====3.1.6.1. Securement of Ballasted Roof Systems==== | |

| + | (Also see [[#9.1.6. Protected Roof Systems | Subsection 9.1.6., "Protected Roof Systems"]]) | ||

| − | + | <ol> | |

| − | {| class="wikitable | + | <li>''Roof systems'' secured with gravel ballast, pavers, or a combination of each, must be designed to resist displacement by ''Specified Wind Loads'', regardless of any ''overburden'' the design may call for. |

| + | <li>The securement of all ''roof systems'' held in place by ballast must be designed by a ''registered professional'' "skilled in the work concerned" ("British Columbia Building Code", Division C, [https://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dcp2s22r2 Section 2.2., "Administration"]), and ballast rates shall conform to | ||

| + | <ol> | ||

| + | <li>the minimum requirements in Table 3.1. (Ref. [[#3.3.5.1. Ballasted Systems | Article 3.3.5.1., "Ballasted Systems"]], and [[#9.3.6. Protected Roof Systems | Subsection 9.3.6., "Protected Roof Systems"]]), or | ||

| + | <li>extrapolated values using ANSI-SPRI RP-4 (latest edition), "Wind Design Standard for Ballasted Single-ply Roofing Systems". | ||

| + | </li></ol> | ||

| + | <li>{{hilite | Ballast size for all ballasted ''roof systems'' shall conform to ASTM D7655/D7655M-12, "Standard Classification for Size of Aggregate Used as Ballast for Membrane Roof Systems". || 2023-June-16 }} | ||

| + | <li>To facilitate resistance to ''Specified Wind Loads'', | ||

| + | <ol> | ||

| + | <li>a filter fabric is required beneath gravel or paver ballast, and | ||

| + | <li>a protection layer is required beneath crushed ballast. | ||

| + | </li></ol> | ||

| + | <li><span class="recommended">On roofs specified to utilize gravel ballast, no fewer than two parallel rows of pavers should be considered for ''Corner'' and ''Edge'' zones, to prevent or reduce wind scouring of the gravel</span>. | ||

| + | <li>When pavers are selected as ballast for a ''roof system'', the ''Design Authority'' must determine the support and placement of pavers to resist displacement by ''Specified Wind Loads''. | ||

| + | </li></ol> | ||

| + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.1., RGC Ballast Guide</small> | ||

| + | |- | ||

| + | ! XPS Insulation<br>Thickness !! Stone Ballast Required Weight !! Ballast Depth<br>(approximate) | ||

| + | |- | ||

| + | | Up to 50.8 mm (2") || 60 Kg/M<sup>2</sup> (12 lb./sf) || 44.45 mm (1-3/4") | ||

| + | |- | ||

| + | | 76.2 mm (3") || 80 Kg/M<sup>2</sup> (17 lb./sf) || 57.15 mm (2-1/4") | ||

| + | |- | ||

| + | | 101.6 mm (4") || 108 Kg/M<sup>2</sup> (22 lb./sf) || 76.2 mm (3") | ||

| + | |- | ||

| + | | 125 mm (5") || 132 Kg/M<sup>2</sup> (27 lb./sf) || 88.9 mm (3-1/2") | ||

| + | |- | ||

| + | | 152.4 mm (6") || 156 Kg/M<sup>2</sup> (32 lb./sf) || 107.95 mm (4-1/4") | ||

| + | |- | ||

| + | | 177.8 mm (7") || 180 Kg/M<sup>2</sup> (37 lb./sf) || 125 mm (5") | ||

| + | |- | ||

| + | | 203.2 mm (8") || 204 Kg/M<sup>2</sup> (42 lb./sf) || 139.7 mm (5-1/2") | ||

|- | |- | ||

| − | |||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ====3.1.6.2. Securement of Modified Protected Roof Systems==== | |

| − | + | <ol> | |

| + | <li>Modified ''protected roof systems'' shall be secured according to the requirements for ''conventionally insulated'' roofs supporting overburden. | ||

| + | </li></ol> | ||

| − | + | ===3.1.7. Roof Replacement and Alterations=== | |

| − | + | ====3.1.7.1. Complete Roof System Replacement==== | |

| − | |||

| − | |||

| − | + | <ol> | |

| + | <li>Complete ''roof system'' replacement ''projects'' must be designed to secure the new ''roof system'' against displacement by ''Specified Wind Loads''. | ||

| + | </li></ol> | ||

| − | + | ====3.1.7.2. Partial Roof System Replacement==== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <ol> | |

| + | <li>Partial roof replacements must be designed to secure the ''roof system'' against displacement by ''Specified Wind Loads'', in keeping with the requirements in [[#3.1.3.2. Calculation of Specified Wind Loads | Article 3.1.3.2.]] (See also [[#3.3.6.2. Partial Roof Replacement | Article 3.3.6.2.]]). | ||

| + | <li>When specifying securement for a partial roof replacement, the securement system must be designed and specified by the ''Design Authority'' (See also [[#1.1.4. Replacement and Alterations | Subsection 1.1.4., "Replacement and Alterations"]]); <span class="recommended">nevertheless, mechanical fastening, when practicable, is the recommended method for securing new materials to an existing ''roof system''</span> (See [[Notes to SBS Standard#A-3.7.7.2. | Note A-3.1.7.2.]]). | ||

| + | </li></ol> | ||

| − | + | ==Section 3.2. Materials== | |

| − | + | ===3.2.1. Material Properties=== | |

| − | + | ====3.2.1.1. Substituting Materials Used in a Tested Assembly==== | |

| − | + | (See [[Notes to SBS Standard#A-3.2.1.1. | Note A-3.2.1.1.]]) | |

| − | |||

| − | # | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | ==== | + | <ol> |

| + | <li>{{hilite | When a manufacturer's ''Tested Assembly'' incorporates materials (and listed alternates) that are not part of the '''''RoofStar Guarantee Program''''', the ''Design Authority'' must identify appropriate substitutions for those materials from the list of|| 2021-October-30 }} [http://rpm.rcabc.org/index.php?title=Division_C:_Accepted_Materials RoofStar-accepted Materials], and obtain | ||

| + | <ol> | ||

| + | <li>{{hilite | written approval from the technical manager of the ''manufacturer'' stating that the substituting material will not reduce the capabilities of the ''Tested Assembly''|| 2021-October-30 }}, or | ||

| + | <li>{{hilite | a letter of support issued by a registered professional qualified to perform the work in Part 4 of the Building Code (Ref. the "British Columbia Building Code", Division C, Part 2, [http://free.bcpublications.ca/civix/document/id/public/bcbc2018/bcbc_2018dcp2s22r2 Article 2.2.1.2., "Structural Design"])|| 2021-October-30 }}. | ||

| + | </li></ol> | ||

| + | <li><span class="principles">{{hilite | Any material substitution should|| 2021-October-30 }}</span> | ||

| + | <ol> | ||

| + | <li><span class="principles">{{hilite | be limited to one (1) material component from the ''Tested Assembly'', but the substitution of more than one material component is permissible provided the substitution complies with the other requirements in this Article|| 2021-October-30 }}</span>, and | ||

| + | <li><span class="principles">{{hilite | be made in keeping with the decision process flows for MARS, PARS and AARS assemblies published in|| 2021-October-30 }}</span> CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition), "Annex F". | ||

| + | </li></ol> | ||

| + | <li>{{hilite | Because of its nature, a ''new roof assembly'' patterned after an ''Assembly with Proven Past Performance'' does not qualify for material substitution|| 2021-October-30 }}. | ||

| + | </li></ol> | ||

| − | + | ===3.2.2. Securement Materials=== | |

| + | ====3.2.2.1. Fasteners==== | ||

| − | + | <ol> | |

| − | ''' | + | <li>The minimum requirements in this Article apply to any ''roof system'', regardless of requirements published elsewhere. |

| − | + | <li><span class="principles">The ''Design Authority'' should specify the correct type of fastener, keeping in mind</span> | |

| − | + | <ol> | |

| − | + | <li><span class="principles">pull-out strength,</span> and | |

| − | + | <li><span class="principles">corrosion resistance (contributing factors to fastener corrosion may include dissimilar metal contact, excessive building humidity, corrosive chemicals within components of the ''roof system'', or corrosive elements provided within the building envelope etc.)</span>. | |

| − | + | </li></ol> | |

| − | |+ Table 3.2 | + | <li>Fasteners must be capable of securing the ''roof system'' components to resist ''Specified Wind Loads''. |

| + | <li>Unless otherwise permitted in writing by the ''manufacturer'', fasteners shall be resin-coated, self-drilling screws manufactured with recessed heads, and must be used in combination with plates, as shown in Table 3.2. | ||

| + | </li></ol> | ||

| + | {| class="wikitable" style="margin-left: 20pt; margin-right: auto;border-color:#E7E9E9;vertical-align:top;text-align:center;" | ||

| + | |+ <small>Table 3.2., Minimum Fastener and Plate Requirements</small> | ||

| + | |- | ||

| + | ! Material !! Fastener<br>Size !! Plate | ||

| + | |- | ||

| + | | Deck overlays || #12 || 73.03 mm (2-7/8”) Hexagonal, 76.2 mm (3”) Round or Square | ||

| + | |- | ||

| + | | Insulation || #12 || 73.03 mm (2-7/8”) Hexagonal, 76.2 mm (3”) Round or Square | ||

| + | |- | ||

| + | | Insulation Overlays || #12 || 73.03 mm (2-7/8”) Hexagonal, 76.2 mm (3”) Round or Square | ||

|- | |- | ||

| − | + | | Membranes || #14 || Proprietary | |

|- | |- | ||

| − | | | + | |} |

| + | |||

| + | ====3.2.2.2. Adhesives==== | ||

| + | |||

| + | <ol> | ||

| + | <li>{{hilite | Adhesives used to secure any ''roof system'' materials must be acceptable to the ''manufacturer'' and be capable of resisting ''Specified Wind Loads''. || 2023-June-16 }} | ||

| + | <li>Adhesives listed in a selected ''Tested Assembly'' | ||

| + | <ol> | ||

| + | <li>must be used to secure applicable layers within the ''roof system'', and | ||

| + | <li>may be substituted only with products listed in the ''Tested Assembly'' report. | ||

| + | </li></ol> | ||

| + | <li>In the absence of a ''Tested Assembly'', or for adhered and partially adhered ''roof assemblies'' with ''Proven Past Performance'', adhesives used to secure new roofing materials must be acceptable to the ''manufacturer'' and must be demonstrably capable of resisting ''Specified Wind Loads''. | ||

| + | <li>Bitumen used as a hot-applied adhesive must be Type 3 or SEBS. | ||

| + | </li></ol> | ||

| + | |||

| + | ====3.2.2.3. Gravel Ballast==== | ||

| + | (See also Table 3.1. in [[#3.1.6.1. Securement of Ballasted Roof Systems | Article 3.1.6.1.]]) | ||

| + | |||

| + | <ol> | ||

| + | <li>Gravel ballast used to secure a ''roof system'' must be washed (clean) round or crushed stone, and must conform to ASTM D7655/D7655M-12, "Standard Classification for Size of Aggregate Used as Ballast for Membrane Roof Systems", or to Table 3.3. | ||

| + | <li>The minimum requirements in this Article must not be reduced except by a written Variance that shall be endorsed in writing by the owner or the owner's representative, and submitted to the '''''RoofStar Guarantee Program''''' as part of the '''''Guarantee''''' record. | ||

| + | </li></ol> | ||

| + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.3., RGC Ballast Grade Guide</small> | ||

|- | |- | ||

| − | + | ! Nominal size !! Percentage Passing | |

|- | |- | ||

| − | | | + | | 38.1 mm (1-1/2") || 100% |

|- | |- | ||

| − | | | + | | 25.4 mm (1") || 70 - 100% |

|- | |- | ||

| − | | | + | | 19.05 mm (3/4") || 5 - 20 % |

|- | |- | ||

| − | | | + | | 12.7 mm (1/2") || 0 - 6 % |

|- | |- | ||

| − | | | + | | 4.76 mm (3/16") || 0 - 2 % |

|- | |- | ||

|} | |} | ||

| − | ==== | + | ====3.2.2.4. Pavers and Pedestals==== |

| − | |||

| − | |||

| − | + | <ol> | |

| − | + | <li>Pavers that are partially supported (i.e., with pedestals) should be capable of resisting anticipated loads (i.e., hydraulically pressed concrete pavers). | |

| − | + | <li>Pedestals | |

| − | < | + | <ol> |

| − | =====< | + | <li><span class="principles">should be adjustable when a level surface is required</span>, |

| − | + | <li>must be purpose-made, and | |

| − | + | <li>must include an integral spacer rib measuring at least a 3.18 mm (1/8”) in width, to uniformly separate pavers. | |

| − | + | </li></ol> | |

| − | # | + | </li></ol> |

| − | + | ||

| − | + | ==Section 3.3. Application== | |

| − | + | ===3.3.1. Guarantee Term Requirements=== | |

| − | + | ====3.3.1.1. RoofStar 5-year and RoofStar 10-year Guarantee==== | |

| − | + | ||

| − | :{| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" | + | <ol> |

| − | |+ Table 3. | + | <li>To qualify for a '''''RoofStar 5-year''''' or '''''RoofStar 10-year Guarantee''''', all ''projects'' shall comply with the requirements in this Part. |

| + | </li></ol> | ||

| + | |||

| + | ====3.3.1.2. RoofStar 15-Year Guarantee==== | ||

| + | |||

| + | <ol> | ||

| + | <li>All ''projects'' intended to qualify for a '''''RoofStar 15-year Guarantee''''' shall comply with the requirements in this Standard for a '''''RoofStar 5-year''''' or '''''RoofStar 10-year Guarantee''''', and shall | ||

| + | <ol> | ||

| + | <li>conform to the specified design when enhanced ''roof system'' securement is required (See [[#3.1.2.1. RoofStar 5-year and RoofStar 10-year Guarantee | Article 3.1.2.1.]]). | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.3.2. All Systems=== | ||

| + | ====3.3.2.1. Securing Systems with Mechanical Fasteners==== | ||

| + | |||

| + | <ol> | ||

| + | <li>Unless otherwise specified by a ''Tested Assembly'', a ''roof assembly'' with ''Proven Past Performance'', or a custom-engineered ''assembly'', | ||

| + | <ol> | ||

| + | <li>fastener patterns shall conform to Tables 3.5. through 3.10., | ||

| + | <li>the minimum number of fasteners must conform to the requirements in Table 3.4., and | ||

| + | <li>fasteners shall be installed at least 152.4 mm (6”) from panel corners, measured from each edge of the panel, but the precise placement of fasteners shall be confirmed with the ''manufacturer''. | ||

| + | </li></ol> | ||

| + | <li>Fasteners used to secure boards from curling, or to secure boards at slope transitions, shall be additional to the minimum number of fasteners and plates required by a ''Tested Assembly'', a ''roof assembly'' with ''Proven Past Performance'', a custom-engineered ''assembly'', or the patterns shown in Tables 3.4. through 3.10. | ||

| + | <li>When mechanically attached membranes are installed together with new insulation, the ''insulation assembly'' {{hilite | (with or without an ''insulation overlay'')|| 2020-July-3 }} must be held in place independently from the membrane, with no fewer than four (4) fasteners per panel. | ||

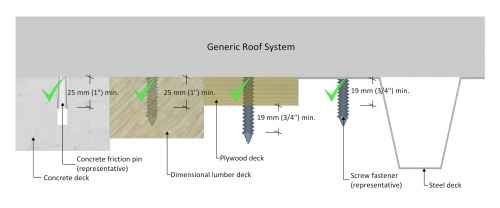

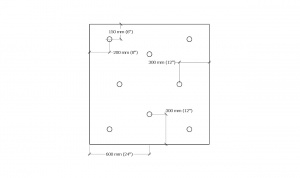

| + | <li>{{hilite | Regardless of where fasteners are used in the ''roof system'', when they penetrate and secure another material to a substrate, mechanical fasteners must conform to the requirements illustrated in {{hilite | Figure 3.4.|| 2021-October-30 }} and shall (unless exceeded by the fastener manufacturer’s published requirements)|| 2020-July-3 }} | ||

| + | <ol> | ||

| + | <li>{{hilite |penetrate through the bottom surface of|| 2021-October-30 }} | ||

| + | <ol> | ||

| + | <li>steel ''decks'' at least 19.05 mm (3/4") (<span class="principles">fasteners should penetrate the top flutes only)</span>, and | ||

| + | <li>{{hilite | plywood sheathing by at least 19.05 mm (3/4")|| 2021-October-30 }}. | ||

| + | </li></ol> | ||

| + | <li>{{hilite |penetrate into solid dimensional lumber or concrete by at least 25.4 mm (1")|| 2021-October-30 }}. | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | :{| class="wikitable" style="background-color:white"; border="#A9A9A9;" | ||

| + | |+ <small>Figure 3.3.2.-A (Click to expand)<br>(Note: these requirements may be exceeded by the fastener manufacturer’s published requirements)</small> | ||

| + | |- | ||

| + | | [[File:Figure 3.5.jpg|link=http://rpm.rcabc.org/images/9/95/Figure_3.5.jpg| 500 px]] | ||

| + | |} | ||

| + | |||

| + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.4., RGC Mechanical Fastening (minimum requirements)</small> | ||

|- | |- | ||

! colspan="1" rowspan="2" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | Material Dimensions | ! colspan="1" rowspan="2" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | Material Dimensions | ||

| Line 292: | Line 479: | ||

! colspan="1" rowspan="1" style="width: 100px;vertical-align:top;text-align:center;background: #A9A9A9;" | Corner | ! colspan="1" rowspan="1" style="width: 100px;vertical-align:top;text-align:center;background: #A9A9A9;" | Corner | ||

|- | |- | ||

| − | ! colspan="1" rowspan="1" style="vertical-align:top;text-align:left;" | | + | ! colspan="1" rowspan="1" style="vertical-align:top;text-align:left;" | 1219.2 mm x 2438.4 mm (48" x 96") || || || |

|- | |- | ||

| style="vertical-align:top;text-align:left;" | Deck Overlay supporting mechanically attached materials || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background:#ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background:#ffffcc;" | 4 | | style="vertical-align:top;text-align:left;" | Deck Overlay supporting mechanically attached materials || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background:#ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background:#ffffcc;" | 4 | ||

|- | |- | ||

| − | | style="vertical-align:top;text-align:left;" | | + | | style="vertical-align:top;text-align:left;" | {{hilite | Insulation or Insulation Overlay supporting mechanically attached materials || 2020-July-3 }} || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | {{hilite | 4 || 2020-July-3 }} || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | {{hilite | 4 || 2020-July-3 }} || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | {{hilite | 4 || 2020-July-3 }} |

|- | |- | ||

| style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 12 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 15 | | style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 12 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 15 | ||

| Line 303: | Line 490: | ||

|- | |- | ||

|} | |} | ||

| − | + | ||

| − | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | | + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" |

| + | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | 1219.2 mm x 1828.8 mm (48" x 72") || || || | ||

|- | |- | ||

| style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 12 | | style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 12 | ||

|- | |- | ||

|} | |} | ||

| − | + | ||

| − | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | | + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" |

| + | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | 1219.2 mm x 1219.2 mm (48" x 48") || || || | ||

|- | |- | ||

| style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 5 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 | | style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 5 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 | ||

|- | |- | ||

|} | |} | ||

| − | + | ||

| − | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | | + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" |

| + | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | 914.4 mm x 1219.2 mm (36" x 48") || || || | ||

|- | |- | ||

| style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 7 | | style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 7 | ||

|- | |- | ||

|} | |} | ||

| − | + | ||

| − | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | | + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" |

| + | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | 609.6 mm x 2438.4 mm (24" x 96") || || || | ||

|- | |- | ||

| style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 5 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 | | style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 5 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 6 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 8 | ||

|- | |- | ||

|} | |} | ||

| − | + | ||

| − | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | | + | {| class="wikitable" style="text-align: left; margin-left: 20pt; margin-right: auto; border: none;" |

| + | ! colspan="1" rowspan="1" style="width: 500px;vertical-align:top;text-align:left;" | 609.6 mm x 1219.2 mm (24" x 48") || || || | ||

|- | |- | ||

| style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 5 | | style="vertical-align:top;text-align:left;" | Insulation || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 4 || style="width: 100px;vertical-align:top;text-align:center;background: #ffffcc;" | 5 | ||

| Line 334: | Line 526: | ||

|} | |} | ||

| − | :{| class="wikitable" style="text-align: center; margin-left: 20pt; margin-right: auto; border: none;" | + | :{{hilite | NOTE: Tables 3.5. through 3.10. illustrate fastener patterns and placement based on historical Guarantee requirements, to provide optimum wind uplift resistance. These patterns are to be used only when patterns are not provided in a ''Tested Assembly'', a ''roof assembly'' with ''Proven Past Performance'', or in a custom-engineered ''assembly''. Fasteners may be located within 50.8 mm (2") of position shown in diagrams in any direction, but this must be validated by the ''manufacturer''. || 2023-June-16 }} |

| − | |+ Table 3. | + | |

| − | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | | + | {| class="wikitable" style="text-align: center; margin-left: 20pt; margin-right: auto; border: none;" |

| + | |+ <small>Table 3.5. (Click on drawing to expand)</small> | ||

| + | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | 1219.2 mm x 2438.4 mm (48" x 96") | ||

|- | |- | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ||

| Line 342: | Line 536: | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ||

|- | |- | ||

| − | | [[File: | + | | style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x8 (4 fasteners).jpg | link=http://rpm.rcabc.org/images/4/4f/Table_3.4_-_4x8_%284_fasteners%29.jpg | 300 px]] '''4 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x8 (4 fasteners).jpg | link=http://rpm.rcabc.org/images/4/4f/Table_3.4_-_4x8_%284_fasteners%29.jpg | 300 px]] '''4 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x8 (4 fasteners).jpg | link=http://rpm.rcabc.org/images/4/4f/Table_3.4_-_4x8_%284_fasteners%29.jpg | 300 px]] '''4 Fasteners''' |

| + | |- | ||

| + | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ||

| + | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Perimeter | ||

| + | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ||

|- | |- | ||

| − | | [[File: | + | | style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x8 (8 fasteners).jpg | link=http://rpm.rcabc.org/images/b/b7/Table_3.4_-_4x8_%288_fasteners%29.jpg | 300 px]] '''8 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x8 (12 fasteners).jpg | link=http://rpm.rcabc.org/images/c/c9/Table_3.4_-_4x8_%2812_fasteners%29.jpg | 300 px]] '''12 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x8 (15 fasteners).jpg | link=http://rpm.rcabc.org/images/5/58/Table_3.4_-_4x8_%2815_fasteners%29.jpg | 300 px]] '''15 Fasteners''' |

|- | |- | ||

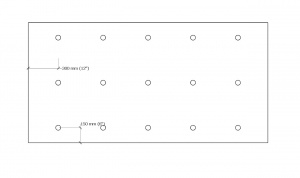

| − | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | | + | |} |

| + | |||

| + | {| class="wikitable" style="text-align: center; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.6. (Click on drawing to expand)</small> | ||

| + | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | 1219.2 mm x 1828.8 mm (48" x 72") | ||

|- | |- | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ||

| Line 352: | Line 554: | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ||

|- | |- | ||

| − | | [[File: | + | | style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 4x6 (6 fasteners).jpg | link=http://rpm.rcabc.org/images/9/94/Table_3.5_-_4x6_%286_fasteners%29.jpg | 300 px]] '''6 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 4x6 (8 fasteners).jpg | link=http://rpm.rcabc.org/images/8/88/Table_3.5_-_4x6_%288_fasteners%29.jpg | 300px]] '''8 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 4x6 (12 fasteners).jpg | link=http://rpm.rcabc.org/images/c/c7/Table_3.5_-_4x6_%2812_fasteners%29.jpg | 300 px]] '''12 Fasteners''' |

|- | |- | ||

| − | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | | + | |} |

| + | |||

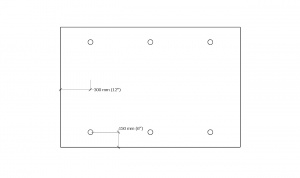

| + | {| class="wikitable" style="text-align: center; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.7. (Click on drawing to expand)</small> | ||

| + | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | 1219.2 mm x 1219.2 mm (48" x 48") | ||

|- | |- | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ||

| Line 360: | Line 566: | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ||

|- | |- | ||

| − | | [[File: | + | | style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x4 (5 fasteners).jpg | link=http://rpm.rcabc.org/images/f/f6/Table_3.4_-_4x4_%285_fasteners%29.jpg | 300 px]] '''5 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x4 (6 fasteners).jpg | link=http://rpm.rcabc.org/images/7/76/Table_3.4_-_4x4_%286_fasteners%29.jpg | 300 px]] '''6 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.4 - 4x4 (8 fasteners).jpg | link=http://rpm.rcabc.org/images/7/76/Table_3.4_-_4x4_%288_fasteners%29.jpg | 300 px]] '''8 Fasteners''' |

|- | |- | ||

| − | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | | + | |} |

| + | |||

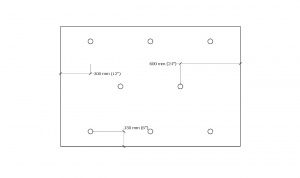

| + | {| class="wikitable" style="text-align: center; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.8. (Click on drawing to expand)</small> | ||

| + | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | 914.4 mm x 1219.2 mm (36" x 48") | ||

|- | |- | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ||

| Line 368: | Line 578: | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ||

|- | |- | ||

| − | | [[File: | + | | style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 3x4 (4 fasteners).jpg | link=http://rpm.rcabc.org/images/9/9f/Table_3.5_-_3x4_%284_fasteners%29.jpg | 300 px]] '''4 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 3x4 (6 fasteners).jpg | link=http://rpm.rcabc.org/images/d/d1/Table_3.5_-_3x4_%286_fasteners%29.jpg | 300 px]] '''6 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 3x4 (7 fasteners).jpg | link=http://rpm.rcabc.org/images/e/ed/Table_3.5_-_3x4_%287_fasteners%29.jpg | 300 px]] '''7 Fasteners''' |

|- | |- | ||

| − | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | | + | |} |

| + | |||

| + | {| class="wikitable" style="text-align: center; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.9. (Click on drawing to expand)</small> | ||

| + | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | 609.6 mm x 2438.4 mm (24" x 96") | ||

|- | |- | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ||

| Line 376: | Line 590: | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ||

|- | |- | ||

| − | | [[File: | + | | style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 2x8 (5 fasteners).jpg | link=http://rpm.rcabc.org/images/3/39/Table_3.5_-_2x8_%285_fasteners%29.jpg | 300 px]] '''5 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 2x8 (6 fasteners).jpg | link=http://rpm.rcabc.org/images/6/69/Table_3.5_-_2x8_%286_fasteners%29.jpg | 300 px]] '''6 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 2x8 (8 fasteners).jpg | link=http://rpm.rcabc.org/images/7/76/Table_3.5_-_2x8_%288_fasteners%29.jpg | 300 px]] '''8 Fasteners''' |

|- | |- | ||

| − | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | | + | |} |

| + | |||

| + | {| class="wikitable" style="text-align: center; margin-left: 20pt; margin-right: auto; border: none;" | ||

| + | |+ <small>Table 3.10. (Click on drawing to expand)</small> | ||

| + | ! colspan="3" rowspan="1" style="width: 500px;vertical-align:centre;text-align:center;background: #A9A9A9;" | 609.6 mm x 1219.2 mm (24" x 48") | ||

|- | |- | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Field | ||

| Line 384: | Line 602: | ||

! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ! colspan="1" rowspan="1" style="width: 300px; vertical-align:top;text-align:center;" | Corner | ||

|- | |- | ||

| − | | [[File: | + | | style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 2x4 (4 fasteners).jpg | link=http://rpm.rcabc.org/images/f/f9/Table_3.5_-_2x4_%284_fasteners%29.jpg | 300 px]] '''4 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 2x4 (4 fasteners).jpg | link=http://rpm.rcabc.org/images/f/f9/Table_3.5_-_2x4_%284_fasteners%29.jpg | 300 px]] '''4 Fasteners''' || style="width: 100px;vertical-align:top;text-align:center;background: #fff;" | [[File:Table 3.5 - 2x4 (5 fasteners).jpg | link=http://rpm.rcabc.org/images/b/b3/Table_3.5_-_2x4_%285_fasteners%29.jpg | 300 px]] '''5 Fasteners''' |

|- | |- | ||

|} | |} | ||

| − | + | ====3.3.2.2. Securing Systems with Adhesives==== | |

| + | |||

| + | <ol> | ||

| + | <li><span class="principles">Adhesives may be used to secure new roofing materials to an existing ''roof system''</span>, provided the specific application procedures and methods are engineered by or for the ''Design Authority''. | ||

| + | <li>Notwithstanding Sentence (1), the use of adhesive to secure insulation shall conform to [[#7.3.3.1. Adhesive-applied Insulation | Article 7.3.3.1.]] | ||

| + | </li></ol> | ||

| + | |||

| + | ====3.3.2.3. Securing Roofs with Overburden==== | ||

| + | |||

| + | <ol> | ||

| + | <li>Any ''overburden'', including ''Vegetated Roof Systems'', must be installed in keeping with the designed securement methods and systems specified by the ''Design Authority'', and in alignment with the requirements in [[#Part 14 - The Roof as a Platform | Part 14]]. | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.3.3. Conventionally Insulated Roof Systems=== | ||

| + | (The requirements in [[#3.3.2. All Systems | Subsection 3.3.2., "All Systems"]], shall be read together with the following articles) | ||

| + | |||

| + | ====3.3.3.1. General Requirements==== | ||

| + | |||

| + | <ol> | ||

| + | <li>New and fully replaced ''Conventionally Insulated Systems'' must be secured to conform to the Building Code, and shall be capable of resisting displacement by ''Specified Wind Loads'' using | ||

| + | <ol> | ||

| + | <li>a ''Tested Assembly'', | ||

| + | <li>an ''Assembly with Proven Past Performance'', or | ||

| + | <li>an ''assembly'' with custom-engineered securement. | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.3.4. Uninsulated Systems=== | ||

| + | (The requirements in [[#3.3.2. All Systems | Subsection 3.3.2., "All Systems"]], shall be read together with the following articles) | ||

| + | |||

| + | ====3.3.4.1. General Requirements==== | ||

| + | |||

| + | <ol> | ||

| + | <li>All uninsulated ''roof systems'' that are not secured with ballast shall conform to the requirements in [[#3.1.4.1. Securement Against Specified Wind Loads | Article 3.1.4.1.]] for ''conventionally insulated systems''. | ||

| + | <li>Uninsulated ''roof systems'' secured with gravel ballast, pavers or both must be installed following the requirements in [[#3.3.5.1. Ballasted Systems|Article 3.3.5.1.]] | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.3.5. Protected Roof Systems=== | ||

| + | (The requirements in [[#3.3.2. All Systems | Subsection 3.3.2., "All Systems"]], shall be read together with the following articles) | ||

| + | |||

| + | ====3.3.5.1. Ballasted Systems==== | ||

| + | (Note: the reader must consult the Design and Application requirements for ''protected roof systems'' in [[#Part 9 - Roof Field (Membrane Systems) | Part 9]]). | ||

| − | == | + | <ol> |

| − | + | <li>''Roof systems'' secured with gravel ballast, pavers, or both must be constructed to resist displacement by ''Specified Wind Loads''. | |

| − | + | <li>To facilitate resistance to ''Specified Wind Loads'', | |

| − | < | + | <ol> |

| + | <li>a filter fabric is required beneath gravel or paver ballast, | ||

| + | <li>a protection layer is required beneath crushed ballast, and | ||

| + | <li>gravel ballast must conform to the specified design. | ||

| + | </li></ol> | ||

| + | <li>Gravel ballast shall | ||

| + | <ol> | ||

| + | <li>be washed (clean) round or crushed stone, and | ||

| + | <li>be selected (according to the specified design) to resist flotation and ''Specified Wind Loads''. | ||

| + | </li></ol> | ||

| + | <li>Pavers and unit-type masonry, such as brick or stone, must be supported by | ||

| + | <ol> | ||

| + | <li>purpose-made pedestals conforming to the requirements in [[#3.2.2.4. Pavers and Pedestals | Article 3.2.2.4.]], | ||

| + | <li>a proprietary drainage layer overlaid with a filter fabric mat, or | ||

| + | <li>a drainage layer of loose aggregate (such as pea gravel) measuring at least 25.4 mm (1”) in depth, installed over a filter fabric. | ||

| + | </li></ol> | ||

| + | <li>Pedestals | ||

| + | <ol> | ||

| + | <li>must permit at least 12.7 mm (1/2″) of vertical separation between the paver and the underlying substrate, to provide airflow for drying surfaces and assist in leveling, | ||

| + | <li><span class="principles">should not impede the flow of water or air, and</span> | ||

| + | <li><span class="principles">should uniformly distribute the dead load of pavers, and other unit masonry products, as well as predicted live loads</span>. | ||

| + | </li></ol> | ||

| + | <li>Pavers must be tied together when specified by the design. | ||

| + | </li></ol> | ||

| + | |||

| + | ===3.3.6. Roof Replacement and Alterations=== | ||

| + | ====3.3.6.1. Complete Roof System Replacement==== | ||

| + | |||

| + | <ol> | ||

| + | <li>''Roof systems'' that are removed and replaced in their entirety (excluding the air or vapour controls, which may be left in place at the discretion of the ''Design Authority'') must be secured following the requirements for new ''roof systems''. | ||

| + | </li></ol> | ||

| + | ====3.3.6.2. Partial Roof Replacement==== | ||

| − | [[ | + | <ol> |

| + | <li>When only a portion of an existing ''roof system'' is specified for replacement, the new materials must be secured to resist ''Specified Wind Loads'' (See also [[#1.1.4. Replacement and Alterations | Subsection 1.1.4., "Replacement and Alterations"]]). | ||

| + | <li>Mechanical fastening is the most reliable method for securing new materials installed over an existing ''roof assembly'', but when mechanical fastening is not practicable, the ''system'' of securement must be | ||

| + | <ol> | ||

| + | <li>custom-engineered, or | ||

| + | <li>patterned after a ''roof assembly'' with ''Proven Past Performance'', in keeping with the requirements in [[#3.1.4.3. Specifying an Assembly with Proven Past Performance | Article 3.1.4.3.]] | ||

| + | </ol></li> | ||

| + | </ol></li> | ||

| − | |||

</div><!-- mainBodyDiv --> | </div><!-- mainBodyDiv --> | ||

</div><!-- row --> | </div><!-- row --> | ||

| − | <div | + | <div class="col-md-12"> |

| − | + | <hr> | |

| − | < | + | |

| − | + | [[Waterproofing Systems|<i class="fa fa-chevron-circle-left" ></i> ''Waterproofing Systems'']] | |

| + | |||

| + | [[Main Page | <i class="fa fa-home fa"></i> Home]] | ||

</div> | </div> | ||

| + | |||

| + | {{Tempate:RPM Page Footer with Copyright and Current Date}} | ||

Latest revision as of 21:22, 3 October 2023

Contents

- 1 Section 3.1. Design

- 2 Section 3.2. Materials

- 3 Section 3.3. Application

Wind Uplift Resource Centre

Securing the Roof Assembly

|

The following content is replicated from Part 3 of the Standard for SBS-modified Bitumen Membrane Roof Systems, located in Division B: Standards, and is largely identical to Part 3 found in any of the other membrane Standards available in this Manual. As a Part of an entire Standard, it must be read together with all the other Parts. |

Click on the gif above to see the full high-definition video, which illustrates why roof system securement requirements matter (NOTE: the video shows a mechanically fastened, conventionally insulated EPDM roof system constructed to the RoofStar Guarantee Standard of the time (2013). The membrane "flutter" in wind is common for this type of roof system).

Section 3.1. Design

3.1.1. General

3.1.1.1. Scope

(See Note A-3.1.1.1.)

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

- This Part applies to all new roofs, and to both full and partial replacement roof systems.

- This Part sets out the requirements for

- material substitution (applicable to Tested Assemblies),

- fastener and adhesive application (minimum numbers and spacing),

- roofs that support overburden, or fixed amenities and equipment, and

- roofs where only part of the system must be replaced.

- Conventionally insulated roof systems designed and constructed with sheet membranes must be secured using

- a Tested Assembly (a membrane roof system, together with a specified roof deck, tested for its wind resistance capabilities using CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition)(See Note A-3.1.1.1.(4)), or

- an Assembly with Proven Past Performance (an existing, representative roof system, together with a specified roof deck, which is used as a “proven” pattern for securing a new roof system on the building under consideration; see Article 3.1.4.3.).

- When neither of the foregoing options is available to the Design Authority to conform to the Code, the roof system must be secured using a custom engineered design (See Article 3.1.4.4.).

3.1.1.2. Intent

(See Note A-3.1.1.2.)

- The requirements in this Part intend to support and conform to or exceed the Building Code.

3.1.1.3. Limit of Liability under RoofStar Guarantee

- Notwithstanding Article 3.1.1.2., the materials presented herein are based on an interpretation of the Code and are not the Code itself; therefore, the reader is responsible to exercise good judgement, and to read, understand and comply with the Code, as and how it applies to the reader’s particular project and its design requirements.

- Where the Code can be shown to exceed the requirements, guiding principles, and recommendations of this Part or any related Part in this Standard, the Code shall prevail.

- Compliance with this Part or the Code does not guarantee that a roof will not succumb to forces exerted by wind, and therefore neither the Guarantor nor the Contractor will accept any responsibility for damage to, or failure of, a roof system caused by wind; too many variables beyond the control of this Standard affect the wind resistance performance of a roof system, including (without limitation)

- the continuity or discontinuity of air and vapour control layers of the entire building enclosure,

- openings in the building (windows and doors, which are often occupant-controlled and not static), and

- wind strength, which may exceed the codified numeric wind speed values used to calculate wind resistance for the roof system (Ref. "British Columbia Building Code", Division B, Appendix C, "Table C-1").

3.1.1.4. Definitions

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part:

- CSA Standard means the CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition).

- Registered Professional has the same meaning as that used in the "British Columbia Building Code", Division C, Section 2.2., "Administration".

- Specified Wind Load means the calculated force of wind exerted on the roof of a specific building, according to the requirements in the "British Columbia Building Code", Division B, Part 4, Section 4.1., "Structural Loads and Procedures".

- System of securement means a specific pattern of mechanical fasteners or adhesives, including specific materials or brands, size, and spacing.

3.1.2. Guarantee Term Requirements

3.1.2.1. RoofStar 5-year and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

3.1.2.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Part for a RoofStar 5-year or RoofStar 10-year Guarantee, and shall

- comply with the higher securement requirements when enhanced roof system securement is required by the membrane manufacturer, to meet their system warranty requirements ("enhanced securement" may exceed the securement stated or specified in a Tested Assembly, an Assembly with Proven Past Performance, or a custom-engineered design; see also Article 1.1.2.1., RoofStar 15-Year Guarantee, for further general requirements).

3.1.3. All Systems

3.1.3.1. Responsibility for Design

- The Design Authority is responsible for determining Specified Wind Loads for each roof system and each roof area of a project, including roofs that support Vegetated Roof Systems or any other overburden, amenities, or equipment.

- Acceptance of a roof for a RoofStar Guarantee is predicated on the assumption that the Design Authority has performed Due Diligence with respect to Specified Wind Loads and has provided the Contractor with sufficient information to construct a roof system that complies with the Code.

3.1.3.2. Calculation of Specified Wind Loads